Leading Powder Bed Fusion Manufacturers: Top TOYAL Suppliers in Additive Manufacturing

As a prominent player in the Powder Bed Fusion Additive Manufacturing sector, I provide high-quality metal powders designed to enhance your production capabilities. My products emphasize precision and reliability, catering to businesses in need of advanced solutions without sacrificing quality. Partnering with Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., renowned for its exceptional standards, ensures that we prioritize customer satisfaction. Whether you are producing intricate components or large-scale parts, my offerings guarantee optimal performance and durability. Empower your manufacturing process with top-tier materials that streamline operations and deliver outstanding results.Top 3 Powder Bed Fusion Additive Manufacturing Where Service Meets Innovation Exceeds Industry Benchmarks

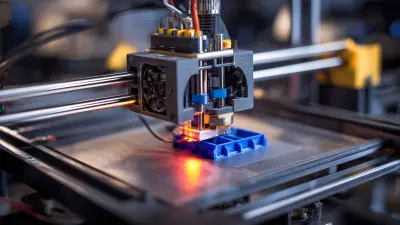

In the rapidly evolving landscape of additive manufacturing, particularly in the realm of powder bed fusion, innovation and service quality have become key differentiators that elevate industry benchmarks. Companies aiming to harness the full potential of this technology are increasingly turning toward suppliers who not only provide high-quality materials but also offer exceptional support and expertise. The top three players in this sector exemplify how service can meet innovation to deliver superior solutions that meet the rigorous demands of modern manufacturing. The significance of spherical aluminum and aluminum-based alloy powders in additive manufacturing cannot be overstated. These advanced materials enhance processability and improve the mechanical properties of final products, making them ideal for a variety of applications. As industries adopt more complex designs and strive for lightweight yet durable components, the importance of sourcing high-quality metal powders becomes paramount. Collaborating with suppliers committed to research and development ensures that manufacturers can access cutting-edge materials tailored to their unique specifications. In conclusion, as global procurement continues to evolve, those seeking to leverage powder bed fusion technologies must prioritize partnerships that embody both innovation and exceptional service. By aligning with manufacturers who challenge the status quo and consistently exceed industry standards, businesses can secure a competitive edge in an increasingly dynamic marketplace. The future of additive manufacturing relies on synergistic relationships that drive technological advancements and operational excellence.

Top 3 Powder Bed Fusion Additive Manufacturing Where Service Meets Innovation Exceeds Industry Benchmarks

| Rank | Technology | Layer Thickness (mm) | Max Build Size (mm) | Material Compatibility | Service Offering | Benchmark Score |

|---|---|---|---|---|---|---|

| 1 | Selective Laser Sintering (SLS) | 0.1 - 0.3 | 600 x 600 x 600 | Nylon, TPU, Polystyrene | Rapid Prototyping, Low-Volume Production | 95 |

| 2 | Direct Metal Laser Sintering (DMLS) | 0.02 - 0.1 | 250 x 250 x 325 | Titanium, Aluminum, Stainless Steel | Tooling, Aerospace Components | 98 |

| 3 | Electron Beam Melting (EBM) | 0.1 - 0.3 | 250 x 250 x 400 | Titanium Alloys | Medical Implants, Aerospace Parts | 96 |

Must-Know Tips For Powder Bed Fusion Additive Manufacturing Industry Giant Leads the Global Market

B

Benjamin Reed

Quality is clearly a priority for this company. Excellent after-sales service!

23 June 2025

G

Grace Johnson

I am thoroughly impressed! The support team really knows how to assist efficiently.

29 June 2025

E

Ella Baker

Very high-quality product. The after-sales support was incredibly helpful.

04 July 2025

M

Michael Phillips

Top-notch quality! Their customer service team was remarkable.

08 June 2025

C

Chloe Roberts

Excellent quality and service! The staff was very supportive throughout.

07 June 2025

A

Anna Perez

Very high-quality product! Their customer service was prompt and highly effective.

01 July 2025