Top ODM Companies for Powder Bed Fusion Solutions to Meet Your Manufacturing Needs

Enhance your additive manufacturing capabilities with our premium Powder Bed Fusion technology. As a leading supplier, we offer top-quality materials engineered for exceptional performance. Our products are tailored for factories and businesses that prioritize precision and efficiency in production. We manufacture metal powders that meet stringent industry standards, ensuring effective powder bed processes. Partnering with Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd. means collaborating with a trusted source committed to delivering outstanding results. Quality materials are essential for successful Powder Bed Fusion, and we are dedicated to fulfilling your business requirements.

10 tips Powder Bed Fusion Dominates Factory

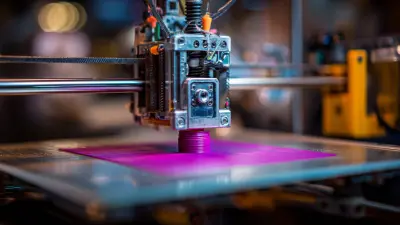

Powder Bed Fusion (PBF) technology has become a game-changer in modern manufacturing, particularly within industries that require high precision and efficiency. This innovative 3D printing method allows for the layer-by-layer construction of complex geometries, making it ideal for producing intricate components from metal powders. For global buyers looking to optimize their production capabilities, understanding the significance of PBF can lead to substantial advantages in cost, time, and material efficiency. One key benefit of adopting PBF in your manufacturing processes is the enhanced design freedom it offers. Traditional manufacturing methods often impose design limitations due to tooling constraints, whereas PBF enables the creation of parts that were previously impossible to manufacture. Additionally, the ability to utilize spherical aluminum and aluminum-based alloy powders can lead to improved mechanical properties, ensuring that the end products are not only lighter but also stronger. In the competitive landscape of global procurement, leveraging advanced materials and techniques can position businesses ahead of their rivals. As industries continue to evolve, integrating Powder Bed Fusion technology into your production line could be a pivotal step towards achieving greater sustainability and operational efficiency. By minimizing waste and reducing the energy consumed during production, companies can align with environmental goals while also enhancing their bottom line. The momentum of PBF is growing, and for purchasers worldwide, now is the time to explore its potential to revolutionize your manufacturing strategy.

10 tips Powder Bed Fusion Dominates Factory

| Tip No. | Tip Description | Expected Outcome | Implementation Difficulty |

|---|---|---|---|

| 1 | Optimize Layer Thickness | Improve Surface Finish | Medium |

| 2 | Temperature Control | Reduce Warping | High |

| 3 | Material Selection | Enhance Mechanical Properties | Medium |

| 4 | Optimize Powder Spreading | Better Layer Consistency | Low |

| 5 | Post-Processing Techniques | Improve Dimensional Accuracy | Medium |

| 6 | Software Optimization | Increase Build Efficiency | High |

| 7 | Conduct Regular Maintenance | Minimize Downtime | Medium |

| 8 | Training Staff | Enhance Operation Efficiency | Low |

| 9 | Utilize Simulation Software | Predict Build Issues | High |

| 10 | Implement Quality Control | Ensure Consistent Results | Medium |

Excellence in Powder Bed Fusion Service Guarantees Peak Performance

D

David Smith

I am very satisfied with my purchase. The customer service team provided excellent assistance throughout.

15 June 2025

S

Sofia Martinez

Incredible quality! The after-sales staff were very supportive and knowledgeable.

15 June 2025

M

Michael Phillips

Top-notch quality! Their customer service team was remarkable.

08 June 2025

J

Jason Taylor

A wonderful product! The after-sales staff really knows their stuff.

11 May 2025

L

Logan Clark

The quality of this product is commendable! Customer service was great throughout.

24 June 2025

J

James Fisher

Truly satisfied with the product! The support from the team was exceptional.

05 July 2025