Affordable Powder Bed and Inkjet Head 3D Printing Solutions from Top Suppliers

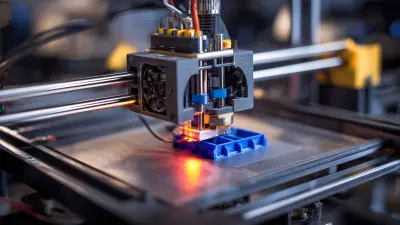

As a prominent player in the 3D printing sector, we recognize the growing demand for innovative solutions such as Powder Bed And Inkjet Head 3d Printing. Our cutting-edge technology enhances precision and efficiency for a wide range of applications. At Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., we are committed to quality and serve as trusted exporters, providing products tailored to your operational needs. Our experienced team is focused on helping businesses achieve their objectives with exceptional service and forward-thinking solutions. Whether in manufacturing or design, our powder bed and inkjet head technology is designed to elevate your projects and give you a competitive advantage in your market. Partner with us to meet your 3D printing requirements effectively!How To Evaluate Powder Bed And Inkjet Head 3d Printing Is The Best Factory

When evaluating the best factory for powder bed and inkjet head 3D printing, there are several critical factors to consider. The quality of metal powders plays a significant role in achieving high-resolution and durable prints. Spherical Aluminium powder and Aluminium-based alloy powders are essential for ensuring a smooth flow throughout the printing process, contributing to both the precision and integrity of the final product. It’s important for procurement managers to thoroughly assess the supplier’s production capabilities and technological innovations, as these can directly impact the consistency and performance of the materials used in additive manufacturing. Another key consideration is the supplier's experience and expertise in the field. Established manufacturers that have a solid track record in R&D and production processes are more likely to provide materials that are tailored to the specific needs of various applications. The reputation of a company, along with its commitment to quality control and customer support, should also be evaluated. Buyers should seek out factories that not only produce high-quality powders but also possess the capability to collaborate on custom projects, ensuring that their unique specifications are met. Lastly, geographic proximity can influence lead times and shipping costs, making it essential for global buyers to consider the logistics involved in procurement. Factories with streamlined processes and efficient supply chains can significantly enhance the overall procurement experience, allowing businesses to maintain timely production schedules. By focusing on these elements when choosing a partner for powder bed and inkjet head 3D printing, global buyers can ensure they are making informed decisions that will contribute to successful outcomes in their manufacturing initiatives.

How To Evaluate Powder Bed And Inkjet Head 3D Printing Is The Best Factory

| Evaluation Criteria | Powder Bed 3d Printing | Inkjet Head 3D Printing |

|---|---|---|

| Layer Resolution | 50 - 100 microns | 25 - 200 microns |

| Material Variety | Metals, Plastics, Ceramics | Polymers, Composites |

| Print Speed | 10 - 20 cm³/hr | 30 - 50 cm³/hr |

| Cost Efficiency | Moderate | High |

| Post-Processing | Requires Sintering | Minimal |

| Strength of Parts | High | Moderate |

| Typical Applications | Aerospace, Automotive | Prototyping, Art |

Pinpointing Powder Bed And Inkjet Head 3d Printing Global Reach Outperforms the Competition

I

Isabella Allen

Impressive product! The support team displayed great professionalism in addressing my concerns.

27 June 2025

J

Jacob Edwards

The craftsmanship is excellent. I was very pleased with the customer service I received.

16 June 2025

N

Natalie Wilson

This product is a cut above the rest! Excellent attention from customer service.

30 June 2025

G

Grace Wood

Quality product! The follow-up service from the team was impressive.

18 May 2025

C

Christopher White

Impressive product! The support team was highly professional and responsive.

27 June 2025

A

Anna White

Impressive quality! The customer service team ensured everything went smoothly.

18 June 2025