How to Choose the Right Materials for 3D Printing in the Metal Manufacturing Field?

As additive manufacturing continues to reshape the production landscape, selecting the right raw materials has become one of the most important decisions for manufacturers striving for precision, performance, and cost efficiency. In fields such as automotive and aerospace, where lightweight and high-strength materials are essential, understanding how to choose suitable metal powders for 3D printing is key. Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., a dedicated manufacturer of Aluminum Powder, offers valuable guidance based on its advanced Aluminum Alloy Powder technology.

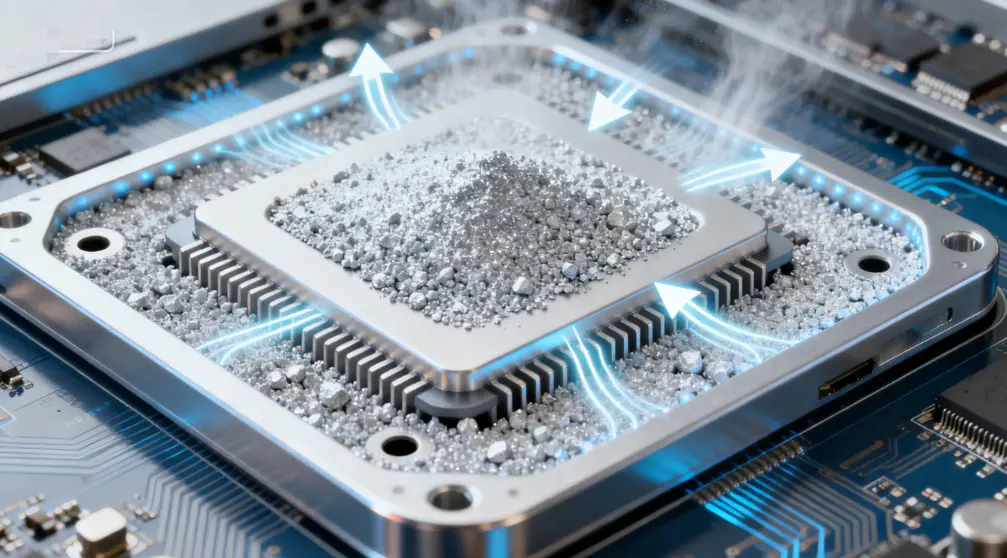

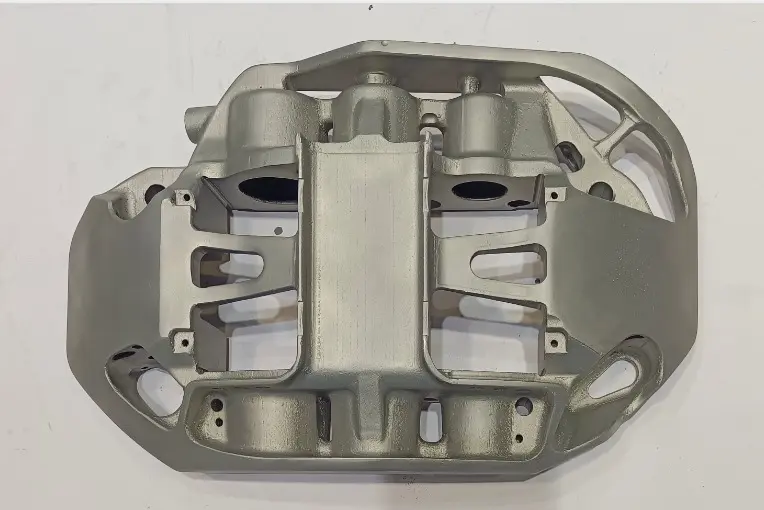

One of the first factors to consider when selecting metal powders is flowability. Good flowability ensures stable powder spreading during the printing process, leading to consistent layer formation and high surface quality. JiWeiXin’s aluminum alloy powder features excellent flow characteristics, making it ideal for high-precision and large-scale additive manufacturing tasks. This is particularly important for complex automotive components such as wheels, brake calipers, and structural brackets, where precise geometry and uniform density are required.

Another critical parameter is oxygen content. Excessive oxygen in metal powders can lead to oxidation, porosity, and reduced mechanical strength in finished parts. JiWeiXin employs strict powder production and inert environment processing techniques to maintain ultra-low oxygen content, ensuring improved strength, enhanced fatigue resistance, and stability under demanding operating conditions. This is especially valuable in aerospace applications, where safety and performance cannot be compromised.

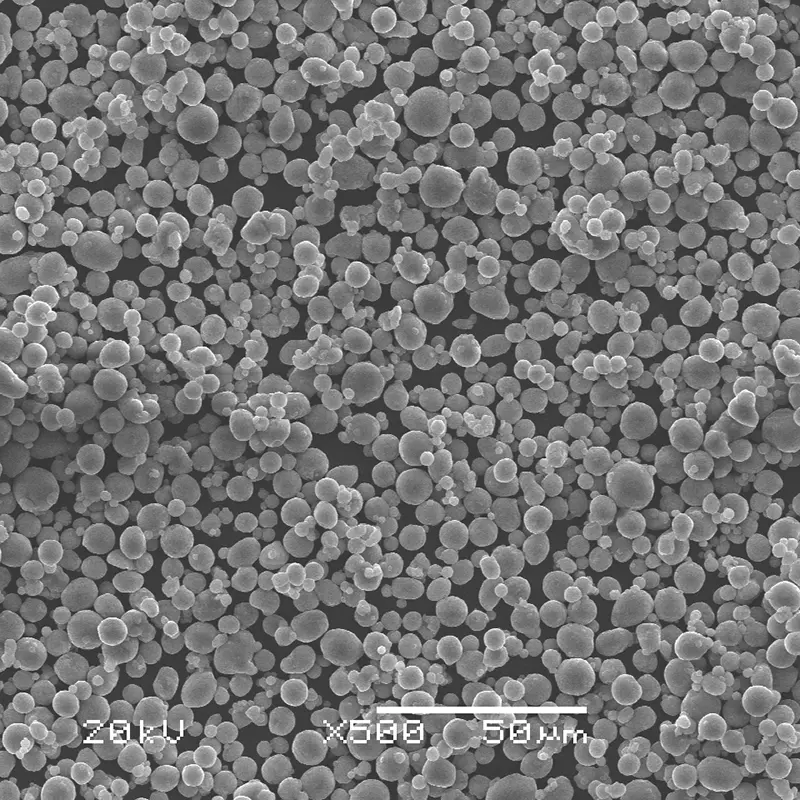

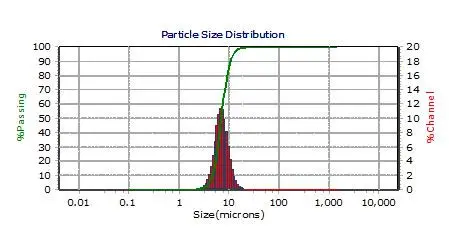

Particle size distribution also plays a key role. A controlled, uniform particle size allows for optimized packing density and smoother surface finish. JiWeiXin’s aluminum alloy powder is available in various particle size ranges to meet diverse printing requirements, from fine-detail precision parts to high-strength functional components. Manufacturers can select customized powder specifications according to their printing equipment and performance needs.

Beyond physical properties, it’s important to evaluate the application intent. Aluminum alloy powders are highly suitable for industries pursuing lightweight solutions. For automotive systems, lightweight components contribute to fuel efficiency and overall performance. In aerospace, weight reduction directly translates into lower energy consumption and operational cost savings. Aluminum alloys provide the perfect balance of strength, corrosion resistance, and cost-effectiveness, making them an excellent choice for high-performance engineering.

“At JiWeiXin, our mission is to provide stable, high-purity aluminum alloy powders that support innovation across global manufacturing sectors,” said a spokesperson for the company. “By focusing on purity control, powder consistency, and customizable formulations, we help customers optimize printing efficiency and achieve better product outcomes.”

As 3D printing continues to accelerate industrial innovation, choosing the right metal powder is more than a technical decision—it is an investment in quality, efficiency, and future competitiveness.

For more information, visit: https://site_b0436501-adc8-42b9-9cd2-2ac7bc3020b8/