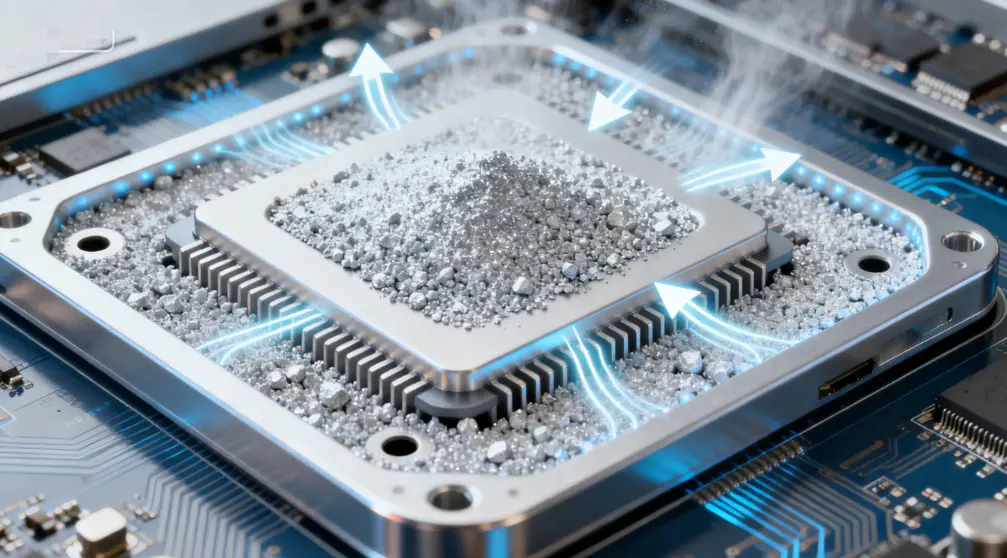

Aluminium Powder in Thermal Management and Heat Dissipation Applications

In modern electronics and industrial equipment, thermal management has become a critical factor that determines product reliability and performance. As devices grow smaller and more powerful, the demand for high-efficiency heat sink fillers and advanced 3d Printing Materials continues to rise. At JiWeiXin, our thermal management aluminium powder solutions are engineered to meet these growing needs with precision, consistency, and proven performance.

Why Aluminium Powder Matters in Thermal Applications

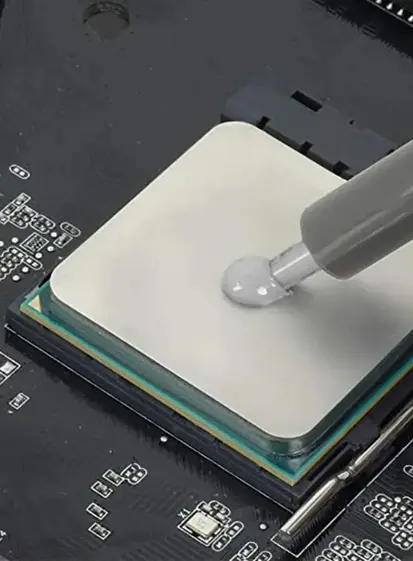

Aluminium is widely recognized for its excellent thermal conductivity, lightweight properties, and corrosion resistance. When processed into high-purity spherical aluminium powder, it becomes a key functional material for heat dissipation products such as thermal interface materials, conductive adhesives, and aluminum-based heat sinks.

JiWeiXin’s aluminium powder for thermal management offers high thermal conductivity combined with easy dispersibility in polymer or resin matrices. This makes it ideal for applications in LED lighting systems, automotive electronics, and power modules — sectors where temperature control directly influences device longevity.

Performance Advantages of JiWeiXin Thermal Management Aluminium Powder

Our products are produced through nitrogen gas atomization, ensuring uniform particle shape, controlled size distribution, and low oxygen content. These characteristics allow better contact between metal particles, significantly enhancing heat transfer pathways.

Key advantages include:

- Superior heat conductivity: Enables faster dissipation of heat in confined electronic environments.

- Excellent sphericity and flowability: Ideal for both coating processes and metal 3D printing materials.

- Stable chemical properties: Ensures long-term performance under varying thermal cycles.

- Customizable particle sizes: Available for powder metallurgy, 3d Printing Powder, and thermally conductive paste formulations.

Integration with 3D Printing and Metal Additive Manufacturing

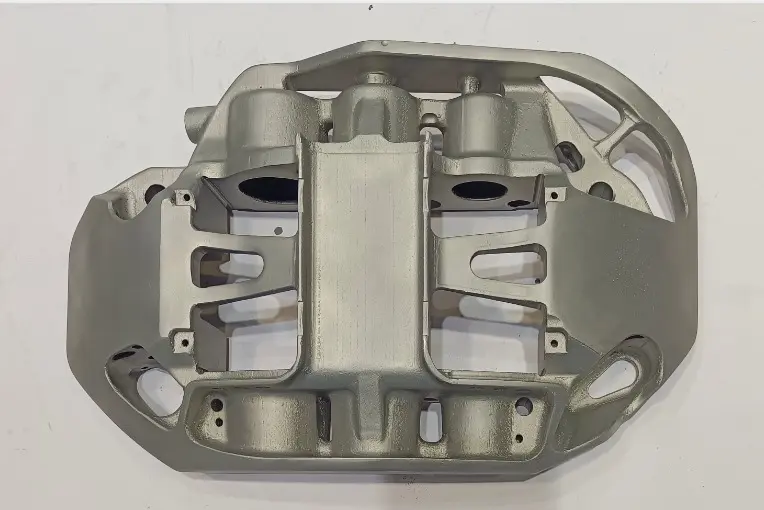

Beyond traditional applications, aluminium powder is also a foundational material in metal 3D printing. JiWeiXin’s advanced metal powder for 3D printing and 3D printing materials have been developed for high-precision components used in automotive, aerospace, and consumer electronics.

These metal 3D printing materials enable designers to create complex geometries with integrated cooling channels, improving heat dissipation efficiency while reducing overall weight. The compatibility between our thermal management aluminium powder and additive manufacturing technologies demonstrates how traditional thermal materials can evolve into modern 3D printing powder applications.

Sustainable and Reliable Supply

JiWeiXin maintains a stable annual production capacity of 10,000 tons, ensuring reliable supply to global partners. Our facility operates under ISO9001:2015 and ISO14001:2015 standards, guaranteeing consistent product quality and environmental responsibility. Each batch of aluminium powder undergoes rigorous inspection for purity, particle size, and thermal conductivity performance before shipment.

Conclusion

As the global push for miniaturization and high-performance devices continues, thermal management aluminium powder plays a vital role in next-generation heat dissipation systems. JiWeiXin remains committed to developing advanced heat sink filler materials and metal powder for 3D printing that deliver both efficiency and reliability.

For more information or technical specifications of our 3D printing powder and thermal-grade aluminium materials, please visit site_b0436501-adc8-42b9-9cd2-2ac7bc3020b8 or contact our technical team for tailored solutions.