Top Metal Sintering Printers Reviewed | Best Picks from TOYAL Manufacturers

For high-quality Metal Sintering Printers, finding a reliable manufacturer is essential. With extensive industry experience, we prioritize precision and durability in every machine produced. Our printers are engineered to meet the demanding requirements of modern manufacturing, ensuring outstanding metal part production. At Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., our state-of-the-art factory utilizes advanced technology for superior performance. As a B2B purchaser, you need equipment that enhances productivity and provides consistent results. We are dedicated to offering exceptional support and customized solutions tailored to your specific needs. Partner with us to elevate your production capabilities and achieve your manufacturing goals!

10 tips Metal Sintering Printer Exceeds Industry Benchmarks Ahead of the Curve

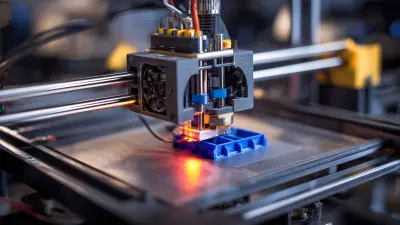

In the rapidly evolving landscape of manufacturing, metal sintering technology is setting unprecedented standards. This blog explores ten essential tips for utilizing metal sintering printers that not only meet but exceed industry benchmarks. As an innovative solution, metal sintering plays a pivotal role in creating high-quality parts with complex geometries and tailored properties, making it a game-changer for manufacturers seeking competitive advantages. To maximize the performance of metal sintering printers, companies should focus on meticulous powder selection, ensuring the use of high-purity spherical metal powders, particularly aluminum and its alloys. These powders significantly enhance flowability and packing density, resulting in superior sintering outcomes. Additionally, attention to process parameters such as temperature and pressure can lead to remarkable improvements in sintered part density and mechanical properties. Investing in advanced R&D and staying informed about the latest advancements in metal powder technology is equally crucial. Collaborating with experts in the field can offer insights into process optimization and new material possibilities. By adopting these strategies, manufacturers can stay ahead of the curve, leveraging metal sintering technology to create durable, lightweight components that meet the high demands of today’s competitive markets.

10 Tips: Metal Sintering Printer Exceeds Industry Benchmarks Ahead of the Curve

| Dimension | Value |

|---|---|

| Print Resolution | 50 microns |

| Build Volume | 300 x 300 x 400 mm |

| Layer Thickness | 0.1 - 1 mm |

| Max Temperature | 1200 °C |

| Material Compatibility | Stainless Steel, Titanium, Aluminum |

| Print Speed | 30 mm/hour |

| User Software | Custom Slicing Software |

| Energy Consumption | 1.5 kWh |

| Warranty | 2 years |

| Price Range | $50,000 - $70,000 |

How To Select Metal Sintering Printer Manufacturers You Can Rely On More Than a Supplier - A Partner

C

Chloe Norton

This product exceeded my expectations. The follow-up service was prompt and professional.

17 May 2025

A

Avery Phillips

Highly satisfied with my purchase. The customer service was proactive and professional.

14 May 2025

N

Natalie Wilson

This product is a cut above the rest! Excellent attention from customer service.

30 June 2025

S

Sophie Wilson

Such a great product! The after-sales team was very knowledgeable.

31 May 2025

T

Taylor Adams

Impressive craft and quality! Customer support was proactive and very professional.

22 May 2025

M

Maya Lewis

Incredible quality and great customer service! They helped me with every question.

19 June 2025