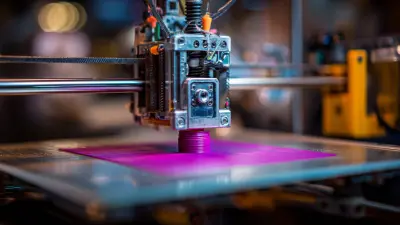

Leading Metal 3D Printing Technologies for OEMs and Exporters in 2023

For high-quality Metal 3D Printing Technologies, partnering with trusted exporters is essential. At Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., we provide outstanding metal powders tailored to meet various application needs. Our focus is on delivering products that exceed industry standards, ensuring your 3D printing projects achieve optimal quality and performance. With our commitment to precision and innovation, we enhance your production processes and support your business in a competitive market. Experience a seamless collaboration where expertise and dedication bring your ideas to life through our advanced technologies and superior materials.Top 5 Metal 3d Printing Technologies From Concept to Delivery Application

The rapid advancements in metal 3D printing technologies have revolutionized manufacturing, enabling innovations from concept to delivery. In this competitive landscape, understanding the top five metal 3D printing technologies can significantly enhance production efficiency and product quality for global purchasers. First, Powder Bed Fusion (PBF) stands out for its ability to create complex geometries with high precision, utilizing a laser or electron beam to fuse metal powders layer by layer. This method is ideal for producing intricate parts with excellent mechanical properties. Next, Directed Energy Deposition (DED) allows for the addition of material during the printing process, making it suitable for repairing components or adding features, leading to reduced waste and enhanced sustainability. Another notable technology is Binder Jetting, which involves applying a liquid binding agent to layers of metal powder, followed by post-processing to achieve the final component. This method is incredibly efficient for producing large quantities of parts at a lower cost. Additionally, Material Extrusion is gaining traction due to its simplicity and the ability to work with various metal feedstocks, making it accessible for smaller manufacturers. Lastly, Hybrid Manufacturing combines traditional machining with 3D printing, optimizing the strengths of both methods for superior end products. Understanding these technologies enables procurement professionals to make informed decisions that align with their production goals and market demands.

Top 5 Metal 3D Printing Technologies From Concept to Delivery Application

| Technology | Process Type | Materials Used | Applications | Pros | Cons |

|---|---|---|---|---|---|

| Selective Laser Melting (SLM) | Powder Bed Fusion | Aluminum, Titanium, Stainless Steel | Aerospace, Medical, Automotive | High precision, Complex geometries | High cost, Slow production speed |

| Electron Beam Melting (EBM) | Powder Bed Fusion | Titanium, Cobalt-Chromium | Aerospace, Medical Implants | Excellent mechanical properties, Minimal residual stress | Equipment cost, Requires vacuum environment |

| Binder Jetting | Binder Jetting | Stainless Steel, Bronze | Jewelry, Art, Prototyping | Fast production, Large build sizes | Lower density, Post-processing required |

| Metal Material Extrusion | Material Extrusion | Steel, Copper, Titanium | Tooling, Aerospace, Automotive | Cost-effective, Good for small runs | Limited material properties, Requires debinding |

| Direct Energy Deposition (DED) | Direct Energy Deposition | Titanium, Nickel Alloys | Repair, Coatings, Aerospace | On-the-fly repair, Versatile materials | Lower build accuracy, Expensive equipment |

Best Way To Metal 3d Printing Technologies Exceeds Industry Benchmarks Market Leader

J

Jessica Miller

Fantastic product with outstanding quality. The support team answered all my queries with great professionalism.

03 July 2025

M

Matthew Anderson

An excellent purchase. The quality stands out, and the support team is incredibly responsive.

29 May 2025

A

Aaliyah Evans

Outstanding experience from start to finish! The service quality was superb.

05 June 2025

S

Sophie Wilson

Such a great product! The after-sales team was very knowledgeable.

31 May 2025

A

Anna White

Impressive quality! The customer service team ensured everything went smoothly.

18 June 2025

L

Lily Clark

Excellent quality! The service staff was friendly and very knowledgeable.

19 May 2025