Top Metal 3D Printers by Leading Companies: Quality Machines for Optimal Performance

Elevate your production capabilities with our high-quality Metal 3D Printer Machine. Designed for precision and reliability, this advanced printer enhances your metal additive manufacturing processes, allowing for the easy creation of complex geometries. Its robust construction ensures durability, while the intuitive interface caters to both experienced professionals and newcomers alike. At Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., we deliver exceptional machinery tailored to your specific business needs. You can trust our commitment to quality, ensuring you invest in a product that fosters innovation and growth. Contact us to learn how our Metal 3D Printer Machine can transform your operations.Tips & Tricks for Metal 3d Printer Machine Trusted by Pros Market Leader

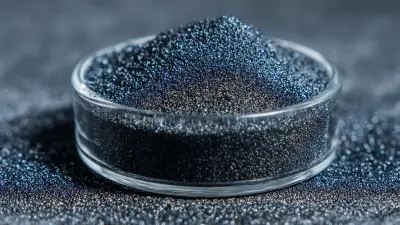

When it comes to maximizing the capabilities of metal 3D printers, both novice and experienced users can benefit from the right tips and tricks. As the demand for advanced manufacturing techniques grows, professionals in the industry rely on efficient and high-quality metal powders to elevate their printing projects. Spherical Aluminum Powder and aluminum-based alloy powders have emerged as essential materials, providing excellent flowability and packing density, which are crucial for achieving intricate designs and robust parts. First, understanding the properties of your metal powder is key. The particle size and shape significantly affect the printing process and the final product’s performance. For instance, using spherical particles can enhance the flow characteristics during the printing process, leading to more uniform layers and reduced porosity in the final part. Additionally, maintaining optimal powder handling practices, such as preventing contamination and ensuring proper storage conditions, will not only prolong the powder's usability but also enhance the quality of the printed components. Furthermore, fine-tuning the printer settings is vital. Each metal powder may require specific parameters regarding temperature, layer thickness, and printing speed to achieve the best results. Keeping up with the latest advancements in printer technology and software can also lead to improved efficiency and output quality. Regularly conducting maintenance on your machines and using reliable suppliers for high-quality materials can establish a solid foundation for successful 3D printing projects, enabling businesses to stay competitive in a rapidly evolving market. By adopting these strategies, professionals can harness the full potential of metal 3D printing and drive innovation in their manufacturing processes.

Tips & Tricks for Metal 3D Printer Machine Trusted by Pros Market Leader

| Tip Category | Tip | Pros' Recommendation |

|---|---|---|

| Material Selection | Choose the right metal powder | Use high-quality, certified powders |

| Printer Settings | Optimize print speed and temperature | Start with manufacturer-recommended settings |

| Post-Processing | Properly cool parts after printing | Avoid warping by gradual cooling |

| Maintenance | Regularly clean the print chamber | Use recommended cleaning supplies |

| Calibration | Calibrate the machine before every job | Run calibration checks every two weeks |

| Layer Management | Adjust layer height based on part size | Use finer layers for intricate designs |

Popular Metal 3d Printer Machine Supplier Guarantees Peak Performance

M

Madison Mitchell

Very durable and well-made product. The after-sales support was incredibly helpful.

20 May 2025

M

Matthew Hill

Premium quality and fantastic service! The staff was very engaging and knowledgeable.

02 July 2025

L

Lily King

I love the quality of this product! The staff were incredibly helpful throughout the process.

21 May 2025

J

James Harris

Impressive quality! The support team is incredibly professional and responsive.

22 June 2025

N

Natalie Wilson

This product is a cut above the rest! Excellent attention from customer service.

30 June 2025

S

Sophie Collins

A great purchasing experience! The quality is impressive and the support team is amazing.

30 May 2025