High-Quality Material Jetting Solutions by TOYAL for Superior 3D Printing Performance

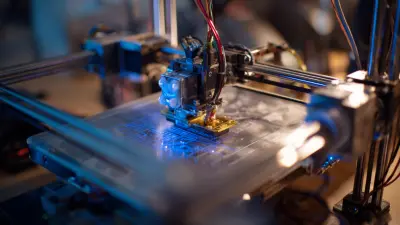

In the realm of advanced manufacturing, Material Jetting stands out as a transformative approach for producing precision parts. At Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., we cater to the specific needs of factories aiming to enhance their production capabilities. Our focus on high-quality material jetting solutions allows for the creation of intricate designs and complex geometries, leading to exceptional results and optimized manufacturing processes. Utilizing cutting-edge technology and premium materials, we ensure that our products consistently meet the highest industry standards.Popular Material Jetting For the Current Year Leads the Global Market

In recent years, material jetting has emerged as a leading technology within the additive manufacturing sector, capturing the interest of global buyers seeking innovative solutions. This technique leverages the capabilities of advanced printing technology to produce intricate and high-quality components with impressive accuracy and detail. As demand for lightweight, high-performance materials increases, industries such as aerospace, automotive, and electronics are exploring the expansive possibilities offered by material jetting. The introduction of spherical aluminium powders and aluminium-based alloy powders has played a pivotal role in this transformative process, resulting in lighter and more durable end products. Spherical aluminium powders, known for their excellent flow characteristics and uniform particle size, significantly enhance the performance of printed components. The refined properties of these powders facilitate improved layer adhesion, reduced porosity, and enhanced surface finish. Moreover, as manufacturers prioritize sustainability, the ability to produce complex geometries with reduced waste makes material jetting an attractive option. This technology not only meets the stringent requirements of modern engineering applications but also aligns with global sustainability goals. As businesses worldwide pivot towards more efficient production techniques, the adoption of material jetting is expected to accelerate. Buyers interested in exploring these advanced materials will find an expanding array of options that cater to their specific needs, allowing for greater customization and innovation in their products. Staying ahead in the competitive global market requires leveraging these advancements, making material jetting a key focus for procurement strategies in the coming years.

Popular Material Jetting For the Current Year Leads the Global Market

| Material Type | Market Share (%) | Growth Rate (CAGR) | Application Area | Key Features |

|---|---|---|---|---|

| Photopolymers | 35 | 15% | Healthcare | High accuracy, smooth surface finish |

| Thermoplastics | 30 | 12% | Aerospace | Durability, heat resistance |

| Metals | 25 | 10% | Automotive | High strength, excellent machinability |

| Ceramics | 10 | 8% | Electronics | Insulation, high temperature resistance |

| Composite Materials | 5 | 18% | Sports Equipment | Lightweight, high strength-to-weight ratio |

Champions of Material Jetting Is The Best Supplies the World’s Top Brands

J

Jessica Miller

Fantastic product with outstanding quality. The support team answered all my queries with great professionalism.

03 July 2025

A

Abigail Stewart

This product is a game-changer! The support staff were courteous and very knowledgeable.

12 May 2025

A

Aaliyah Evans

Outstanding experience from start to finish! The service quality was superb.

05 June 2025

M

Michael Phillips

Top-notch quality! Their customer service team was remarkable.

08 June 2025

C

Chloe Roberts

Excellent quality and service! The staff was very supportive throughout.

07 June 2025

J

James Lewis

A reliable product with excellent quality and service! Highly recommend.

27 May 2025