Top High-Quality Laser Sintering 3D Printers for Companies and Factories

As a leader in advanced manufacturing solutions, we proudly offer our exceptional Laser Sintering 3D Printers, designed for businesses aiming to innovate their production techniques. Renowned for their precision and reliability, our printers effortlessly manage complex geometries. At Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., we are committed to fulfilling the diverse needs of our clients as a trusted exporter and manufacturer in the industry. Our technology promotes rapid prototyping and minimizes material waste, providing a sustainable manufacturing option. By choosing our products, you partner with a dedicated company focused on your success. Our tailored solutions enhance production capabilities across various industries, including aerospace, automotive, and medical. Elevate your business potential with our cutting-edge machinery.Key Steps to Choosing Laser Sintering 3d Printer Sets the Industry Standard Factory-Direct Excellence

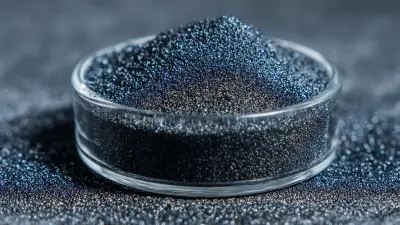

When it comes to selecting a laser sintering 3D printer that meets the industry's highest standards, understanding the fundamental components of the printing process is crucial. The first step involves assessing the types of metal powders available for printing, particularly spherical aluminum and aluminum-based alloy powders, which are known for their superior flowability and packing density. Quality metal powder plays a pivotal role in achieving precision and ensuring optimal mechanical properties in the final product. Therefore, choosing the right supplier with expertise in producing high-quality powders is vital for successful outcomes. Next, consider the technological capabilities of the printers themselves. Advanced laser sintering technologies not only enhance the precision of print but also increase production efficiency. Look for features such as multi-laser systems, which can significantly reduce processing time, and fully integrated software solutions that streamline design-to-production workflows. Additionally, ensure that the printer supports a wide range of materials to facilitate diverse applications, allowing for innovation and versatility in your projects. Lastly, sourcing directly from manufacturers can have a significant impact on both cost and performance. Factory-direct purchasing minimizes markup costs often associated with distributors and ensures that you are receiving the latest technological advancements directly from the source. This ensures not only superior product quality but also access to expert support and resources that can help in resolving any production challenges you may encounter. By taking these key steps, global procurement professionals can confidently invest in laser sintering technologies that comply with industry standards and drive business growth.

Key Steps to Choosing Laser Sintering 3D Printer Sets the Industry Standard Factory-Direct Excellence

| Feature | Importance | Considerations | Examples |

|---|---|---|---|

| Build Volume | High | Ensure it meets your project requirements | 300 x 300 x 300 mm |

| Layer Thickness | Medium | Thinner layers ensure finer details | 20-100 microns |

| Material Compatibility | High | Supports a range of materials | Nylon, TPU, Metal |

| Print Speed | Medium | Faster speeds reduce turnaround time | Up to 100 mm/s |

| User Interface | Medium | Ease of use and accessibility | Touchscreen, Software Integration |

| Post-Processing Options | Low | Availability of finishing tools | Sanding, Painting |

| Technical Support | High | Access to assistance and resources | 24/7 Support, Online Resources |

Premier Laser Sintering 3d Printer Supplies the World’s Top Brands Stands Out

J

James Thompson

The quality speaks for itself, but the outstanding customer service was the cherry on top!

03 July 2025

C

Chloe Norton

This product exceeded my expectations. The follow-up service was prompt and professional.

17 May 2025

S

Sophia Harris

Amazing product quality! The support team was knowledgeable and very helpful.

01 July 2025

M

Michael Phillips

Top-notch quality! Their customer service team was remarkable.

08 June 2025

J

Jason Taylor

A wonderful product! The after-sales staff really knows their stuff.

11 May 2025

J

James Fisher

Truly satisfied with the product! The support from the team was exceptional.

05 July 2025