Laser Powder Bed Fusion: Toyal's Premier Factory Solutions & Export Services

As a key player in the Laser Powder Bed Fusion industry, we at Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd. recognize the critical role of high-quality metal powders in manufacturing. Our extensive range of advanced materials is specifically engineered for Laser Powder Bed Fusion processes. With our foundation in Hunan, we are committed to excellence and innovation, ensuring that our products meet the diverse needs of your applications. Our years of experience guarantee reliability and expertise, making us a trusted partner for businesses aiming to enhance their production capabilities and market competitiveness. Partnering with us means investing in superior materials designed to optimize efficiency and increase output. Let's connect to discuss how our tailored solutions can elevate your operations.Best Options For Laser Powder Bed Fusion Winning in 2025 Service

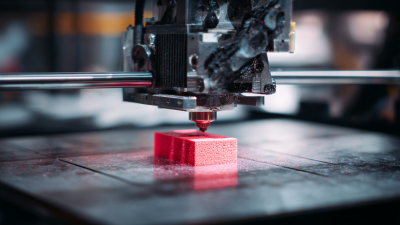

As industries increasingly turn to advanced manufacturing technologies, Laser Powder Bed Fusion (LPBF) stands out as a revolutionary method for creating intricate parts with superior mechanical properties. By harnessing the precision of laser technology, LPBF allows for the production of complex geometries that traditional manufacturing struggles to achieve. In 2025, the focus will shift towards optimizing LPBF techniques, emphasizing the significance of high-quality metal powders in achieving optimal results. For procurement professionals, understanding the crucial role of metal powder in LPBF processes is essential. The selection of the appropriate powder can significantly enhance the efficiency and quality of the manufactured parts. Spherical Aluminum Powders and aluminum-based alloy powders are some of the most promising options for LPBF due to their excellent flowability and packing density, which improve layer uniformity and reduce defects. As the demand for lightweight and high-strength components grows across various industries such as aerospace, automotive, and medical, investing in high-quality metal powders will be critical for staying competitive in the market. Looking ahead, adopting a strategic approach to selecting suppliers of superior metal powders will optimize LPBF outcomes. Collaboration with experienced manufacturers will not only ensure the consistent quality necessary for high-performance applications but also foster innovation in material development. As this technology matures, focusing on cutting-edge material science will drive businesses toward sustainable and efficient production methods, ultimately redefining the future of manufacturing in 2025 and beyond.

Best Options For Laser Powder Bed Fusion Winning in 2025 Service

| Material Type | Applications | Build Speed (cm³/h) | Layer Thickness (mm) | Operating Temperature (°C) |

|---|---|---|---|---|

| Aluminum Alloys | Aerospace, Automotive | 80 | 0.02 - 0.1 | 600 |

| Titanium Alloys | Medical, Aerospace | 50 | 0.01 - 0.08 | 800 |

| Stainless Steel | Tooling, Industrial Parts | 70 | 0.02 - 0.1 | 500 |

| Nickel Alloys | Aerospace, Oil & Gas | 40 | 0.03 - 0.1 | 900 |

| Cobalt Chrome | Medical, Dental | 60 | 0.02 - 0.1 | 700 |

Best Methods To Laser Powder Bed Fusion Delivers Unmatched Quality Factory

D

David Smith

I am very satisfied with my purchase. The customer service team provided excellent assistance throughout.

15 June 2025

J

James Thompson

The quality speaks for itself, but the outstanding customer service was the cherry on top!

03 July 2025

C

Chloe Norton

This product exceeded my expectations. The follow-up service was prompt and professional.

17 May 2025

S

Sophia Harris

Amazing product quality! The support team was knowledgeable and very helpful.

01 July 2025

C

Christopher White

Impressive product! The support team was highly professional and responsive.

27 June 2025

A

Ava Campbell

Been impressed with the quality! The customer support staff was professional and friendly.

26 June 2025