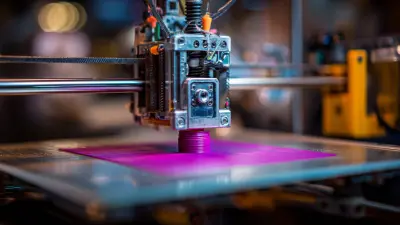

Top Laser Metal Sintering 3D Printers: Best Brands & Suppliers for Quality Builds

When considering a Laser Metal Sintering 3D printer, the TOYAL model stands out for its combination of quality and affordability. Ideal for factories that require reliability and precision in metal printing, this printer excels at transforming metal powder into complex structures with exceptional surface finishes and mechanical properties. Offered by Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., this advanced technology is designed to be accessible for businesses of all sizes. Its seamless integration into production lines enhances efficiency and streamlines processes. For those seeking a high-performing yet cost-effective solution in metal printing, this option proves to be an investment in the future of manufacturing.Where the Value Lies Laser Metal Sintering 3d Printer Now Trending Application

In recent years, the demand for laser metal sintering (LMS) 3D printing technology has surged, revolutionizing various industries by enabling the production of complex metal parts with unprecedented precision and efficiency. This advanced additive manufacturing technique utilizes a high-powered laser to fuse metal powders into solid structures, allowing for intricate designs that are often impossible to achieve through traditional manufacturing methods. The value of LMS technology lies not only in its ability to reduce waste and lead times but also in its capacity to produce lightweight components ideal for aerospace, automotive, and medical applications. As global procurement teams seek to enhance their production capabilities, the focus has shifted towards materials that can optimize the performance and longevity of end products. Spherical Aluminum Powder and aluminum-based alloy powders are particularly noteworthy for their role in improving the sintering process. With their excellent flowability and packing characteristics, these materials enable consistent layer thickness and higher density in the final printed objects, thus ensuring improved mechanical properties. Furthermore, sustainability in manufacturing practices is becoming increasingly important, and LMS adds significant value by minimizing material usage and energy consumption. As companies navigate the competitive landscape, investing in laser metal sintering technology not only positions them at the forefront of innovation but also aligns with global trends towards responsible production. Companies are encouraged to explore this transformative technology to unlock new potential in their manufacturing processes, adapt swiftly to market demands, and meet the needs of a diverse and evolving customer base.

Where the Value Lies: Laser Metal Sintering 3D Printer Now Trending Application

| Application Field | Material Used | Technology Benefits | Cost Efficiency (%) | Market Growth (YoY %) |

|---|---|---|---|---|

| Aerospace | Titanium Alloys | High strength-to-weight ratio | 15% | 12% |

| Medical Devices | Cobalt-Chromium Alloys | Biocompatibility | 20% | 10% |

| Automotive | Aluminum Alloys | Lightweight components | 18% | 8% |

| Tooling | Steel Alloys | Durability and precision | 25% | 15% |

| Jewelry | Precious Metals | Complex designs and customization | 30% | 20% |

Curated Selection of Laser Metal Sintering 3d Printer Pioneers in the Field Outperforms the Competition

L

Laura Garcia

Great value for the price! The after-sales support was exceptional—very professional staff.

24 May 2025

O

Oliver Evans

Fantastic buy! The quality is impressive, and the customer support team was very supportive.

15 May 2025

L

Logan Turner

Great product with high quality! Excellent response from their support team.

15 May 2025

O

Olivia Brown

Very satisfied! The product quality is excellent, and support was outstanding.

05 July 2025

A

Ava Campbell

Been impressed with the quality! The customer support staff was professional and friendly.

26 June 2025

M

Matthew Moore

Exceptional quality! The customer service team has been very professional and attentive.

16 May 2025