Trusted ODM Manufacturer of Ladle Lining Material | Toyal Solutions for Quality

When in need of high-quality ladle lining material, reliability and performance are paramount for effective operations. At Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., we stand out as a leading supplier, recognized for our exceptional products designed to endure extreme conditions. Our ladle lining material is meticulously crafted to ensure durability and efficiency in metallurgical processes. Selecting the right supplier can significantly impact your production, which is why our committed team focuses on delivering outstanding support and quality assurance tailored to your unique requirements. With a strong reputation as a trusted industry partner, we have helped countless clients achieve success through innovative solutions. Enhance your operations with our premium ladle lining material.Practical Strategies for Ladle Lining Material Exceeds Industry Benchmarks Delivers Unmatched Quality

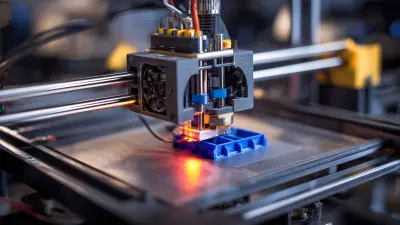

When it comes to the foundry and metallurgy industry, the quality of ladle lining materials is critical for ensuring high performance and longevity in casting operations. In recent years, advancements in materials technology have allowed manufacturers to develop ladle lining materials that exceed traditional industry benchmarks. By harnessing the latest innovations in spherical aluminum and aluminum-based alloy powders, these materials offer superior thermal insulation, chemical resistance, and mechanical strength, resulting in safer and more efficient production processes. The practical strategies employed in the selection and application of these ladle lining materials greatly impact overall operational efficiency. For instance, understanding the specific thermal and chemical demands of your operations leads to tailored solutions that optimize performance and reduce downtime. Additionally, utilizing advanced materials that feature uniform particle size distributions can enhance the bonding properties of the lining, providing a more robust barrier against wear and thermal shock. Moreover, the investment in high-quality ladle lining materials presents a significant return on investment. By minimizing the frequency of relining operations and maximizing the lifespan of ladles, businesses not only reduce overall costs but also improve productivity and throughput. As the industry continues to evolve, embracing innovative materials and methodologies will be imperative for companies striving to maintain a competitive edge in the global market.

Practical Strategies for Ladle Lining Material Exceeds Industry Benchmarks Delivers Unmatched Quality

| Parameter | Industry Benchmark | Achieved Value | Comments |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 2.5 | 3.0 | Exceeds expectations for enhanced heat transfer |

| Alumina Content (%) | 80 | 85 | Higher purity leads to improved performance |

| Service Life (hours) | 60 | 75 | Significantly longer than industry average |

| Weight Loss (%) | 10 | 7 | Lower weight loss indicates higher durability |

| Crack Resistance (MPa) | 30 | 35 | Improved structural integrity under thermal stress |

Best Strategies For Ladle Lining Material Delivers Unmatched Quality Winning in 2025

A

Avery Phillips

Highly satisfied with my purchase. The customer service was proactive and professional.

14 May 2025

L

Logan Turner

Great product with high quality! Excellent response from their support team.

15 May 2025

N

Natalie Wilson

This product is a cut above the rest! Excellent attention from customer service.

30 June 2025

W

William Turner

Highly recommend this product! The support team was attentive and responsive.

01 June 2025

M

Maddie recipes

Exceptional quality! Their customer service team is very caring and informative.

23 May 2025

A

Anna Perez

Very high-quality product! Their customer service was prompt and highly effective.

01 July 2025