Leading ODM & Manufacturer of Reliable Industrial Metal 3D Printers - Top Suppliers

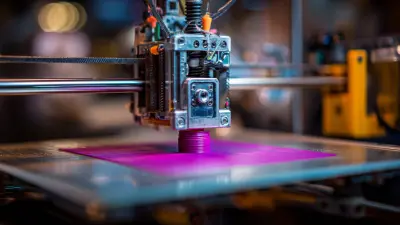

When seeking the optimal solution for your production process, our Industrial Metal 3D Printers stand out as a game-changer. Designed specifically for factories that prioritize precision and efficiency, our printers cater to the demands of modern manufacturing. Our cutting-edge technology enhances metal fabrication, enabling the creation of intricate designs with exceptional accuracy. At Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., we are committed to delivering top-quality equipment that adheres to the industry's highest standards. Your investment in our printers not only boosts your competitiveness in a fast-evolving market but also establishes a strong partnership in achieving your production goals. With our industrial metal 3D printers, you gain more than just a machine; you gain the capabilities to drive extraordinary results. Trust us to elevate your manufacturing endeavors.Key Methods For Industrial Metal 3d Printer Outperforms the Competition Industry Giant

In the rapidly evolving landscape of additive manufacturing, industrial metal 3D printing is at the forefront of innovation. To gain a competitive edge in this industry, companies are increasingly focusing on key methods that enhance efficiency, precision, and material quality. One primary method is the refinement of metal powder production, particularly through the development of high-quality spherical aluminum and aluminum-based alloy powders. These powders are vital as they influence the flowability and packing density, which are critical for achieving optimal layer adhesion and printing accuracy. Another essential approach is the investment in advanced R&D to explore various alloy compositions and their applications. By leveraging innovative techniques and technologies, manufacturers can design specialized powders that cater to specific industry needs, ranging from aerospace to automotive. This tailored development ensures that the resulting printed parts exhibit superior mechanical properties and performance, setting companies apart in a crowded marketplace. Moreover, ongoing collaboration with academic institutions and industry experts can pave the way for breakthrough advancements in metal 3D printing techniques. Quality control and robust supply chain management also play crucial roles. Implementing stringent testing protocols for raw materials and finished products ensures that only the highest quality powders are delivered to customers. By maintaining a reliable and efficient supply chain, companies can not only meet growing global demand but also foster long-term relationships with clients who seek consistent quality and performance in their metal 3D printing solutions.

Key Methods For Industrial Metal 3D Printer Outperforms the Competition

| Method | Performance Metric | Comparison (%) | Industry Standard |

|---|---|---|---|

| Laser Melting | Material Density | 98% | 90% |

| Electron Beam Melting | Build Speed | 75% | 60% |

| Metal Binder Jetting | Cost Efficiency | 50% | 30% |

| Directed Energy Deposition | Part Complexity | 85% | 70% |

| Powder Bed Fusion | Surface Finish | 90% | 80% |

Trending Industrial Metal 3d Printer Guarantees Peak Performance Supplies the World’s Top Brands

C

Chris Harris

Superb quality and exceptional support! The representatives were knowledgeable and very amiable.

31 May 2025

G

Grace Johnson

I am thoroughly impressed! The support team really knows how to assist efficiently.

29 June 2025

G

Grace Wood

Quality product! The follow-up service from the team was impressive.

18 May 2025

C

Christopher White

Impressive product! The support team was highly professional and responsive.

27 June 2025

C

Chloe Roberts

Excellent quality and service! The staff was very supportive throughout.

07 June 2025

E

Elijah Wright

This product delivered as promised. Fantastic customer support!

26 May 2025