High Purity Aluminum Powder ODM Exporter | Trusted Partner of TOYAL

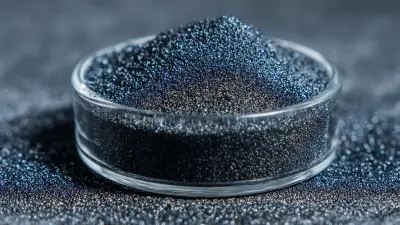

As a leading supplier of High Purity Aluminum Powder, I recognize the unique requirements of manufacturers in need of dependable materials. Our aluminum powder distinguishes itself with its remarkable purity, which ensures enhanced performance across diverse applications, including aerospace and automotive sectors. Partnering with industry frontrunners such as TOYAL, we maintain rigorous quality standards to meet the expectations of our discerning clientele. At Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., we prioritize customer satisfaction, offering timely delivery and competitive pricing to support your production goals. Whether you operate a small enterprise or a large-scale facility, our High Purity Aluminum Powder can significantly elevate the quality of your products. Connect with us to learn how we can become your trusted partner in sourcing top-tier aluminum powder, and let's enhance your manufacturing processes together.Methods To choose High Purity Aluminum Powder Now Trending Manufacturer

When selecting a high purity aluminum powder manufacturer, it's essential to focus on several key factors to ensure you partner with a reliable and reputable supplier. First, consider the manufacturer's experience and expertise in the field. Companies that have been actively involved in the research and development of aluminum powders for several years tend to have a deeper understanding of customer needs and the nuances of production processes. Look for manufacturers that specialize in Spherical Aluminum Powder and aluminum-based alloy powder, as these products often meet higher quality standards and can be tailored for various applications. Another crucial aspect is the quality control measures implemented by the manufacturer. High purity aluminum powder requires precision during production, so it’s beneficial to choose a supplier that adheres to strict quality management systems. Certification such as ISO can be a good indicator of a manufacturer’s commitment to quality and consistency. Additionally, researching customer reviews and case studies can provide insight into the manufacturer’s track record and customer satisfaction rates. Lastly, consider the flexibility and responsiveness of the manufacturer when it comes to order volumes and customization options. A manufacturer who can quickly adapt to changing market demands and provide tailored solutions will be an asset to your supply chain. In a time when industries are evolving rapidly, partnering with a manufacturer who is progressive and innovative will help you stay ahead of the competition and ensure you have access to the best materials for your applications.

Methods To Choose High Purity Aluminum Powder Now Trending Manufacturer

| Parameter | Description | Recommended Value | Current Trends |

|---|---|---|---|

| Purity Level (%) | The percentage of aluminum in the powder without impurities | 99.9 | High demand for 99.9% purity in aerospace applications |

| Particle Size (µm) | The average diameter of aluminum powder particles | 10-500 | Trend towards ultrafine powders for enhanced reactivity |

| Production Method | Method used to produce the aluminum powder | Gas Atomization | Preference for gas atomized powders for uniformity |

| Packaging | Type of packaging used for the powder | Vacuum Sealed Bags | Growing trend for sustainable packaging |

| Applications | Primary use cases for high purity aluminum powders | Aerospace, Electronics, Additive Manufacturing | Increasing use in 3D printing technologies |

How To Decide Between High Purity Aluminum Powder in 2025 Trusted by Pros

M

Madison Mitchell

Very durable and well-made product. The after-sales support was incredibly helpful.

20 May 2025

A

Abigail Stewart

This product is a game-changer! The support staff were courteous and very knowledgeable.

12 May 2025

A

Ariana Foster

A worthwhile investment! The customer support was both knowledgeable and helpful.

01 June 2025

D

David Lopez

Amazing quality! The support team was knowledgeable and gave me great assistance.

23 June 2025

M

Mason Davis

The quality is really impressive! The customer service was friendly and effective.

04 July 2025

A

Anna White

Impressive quality! The customer service team ensured everything went smoothly.

18 June 2025