For High-purity atomized Aluminum Powder

It was collected by sealing atomization, classification, blending and sieving process. During the production process, it is controlled by strict controlling method to keep the particle size distribution and stable chemical content; The powder gets lower oxygen, light weight, excellent reflectivity, good thermal conductivity, high active for reducing high purity rare metals.

Physical properties:

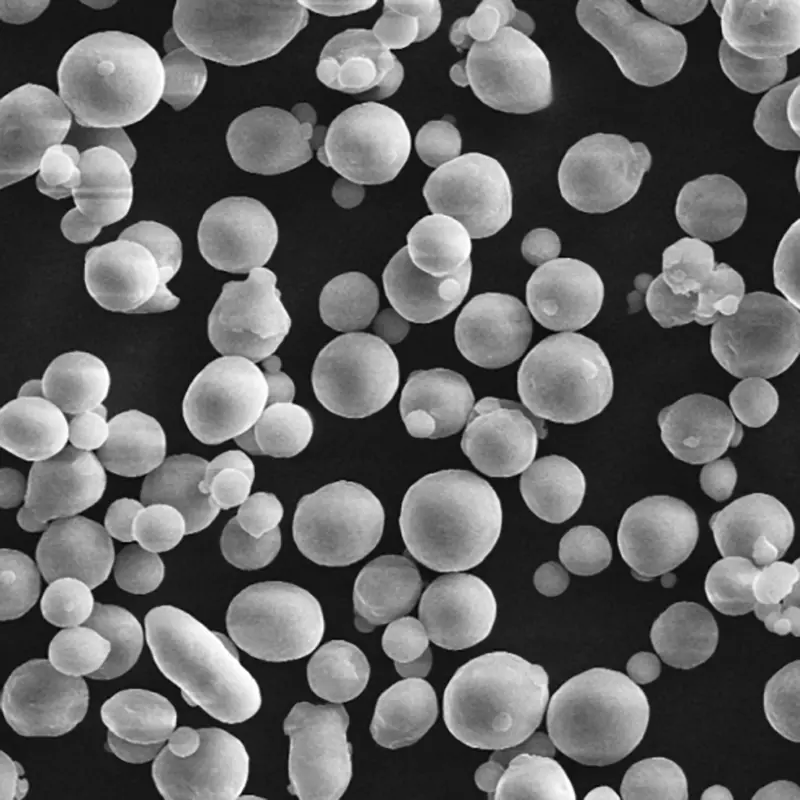

Shape: Spherical

Melting point: 660°C

Density: 2.699g/cm3

Odor: Odorless

Prohibitions: Water, Acid, Alkali, Halogen; Avoid dust spraying in the air and anti-static.

For high-purity aluminum powder: With aluminum purity (Al99.95%, Al99.996%)

Product particle size: 1~2µm, 3~4µm, 5~6µm, 7~8µm, 8~10µm, 20~30µm, 80µm, -325mesh, -200mesh

Packaging conditions: 25Kg/Iron drum, 160Kg/Iron drum, 200Kg/Iron drum with pallet(For special purpose or application, vacuum packaging is available)

Volume: 16 tons, 18 tons(Per 20FCL)

Transportation: By road, by air or by sea

Capacity: 1,000 tons annually

Delivery time: DG inspection, About 2~3 months

Compliance:

Quality control system: GB/T19001:2016 /ISO9001:2015

Environment control system: GB/T 24001:2016 /ISO14001:2015

Quality Assurance:

ICP for testing incoming impurities of aluminum ingot

Laser diffraction testing machine for testing particle size

Moisture tester for testing water content

Oxygen content machine for oxygen volume

Application:

Sputtering target

Powder metallurgy

Trimethylaluminum(TMA)

High-grade metal pigment

High purity alumina

Laminated foil

Reducing agent for high-purity metal

Aluminum nitride

Al Metal matrix composite MMC

Catalyst

Field:

Aviation and Aerospace

Automobile

Semiconductor

Industrial use