For Aluminum metal matrix composite

It was collected by sealing atomization, classification, blending and sieving process. During the production process, it is controlled by strict controlling method to keep the particle size distribution and stable chemical content; The powder is light weight, good thermal conductivity, excellent mechanical properties and good wear resistance.

Physical properties:

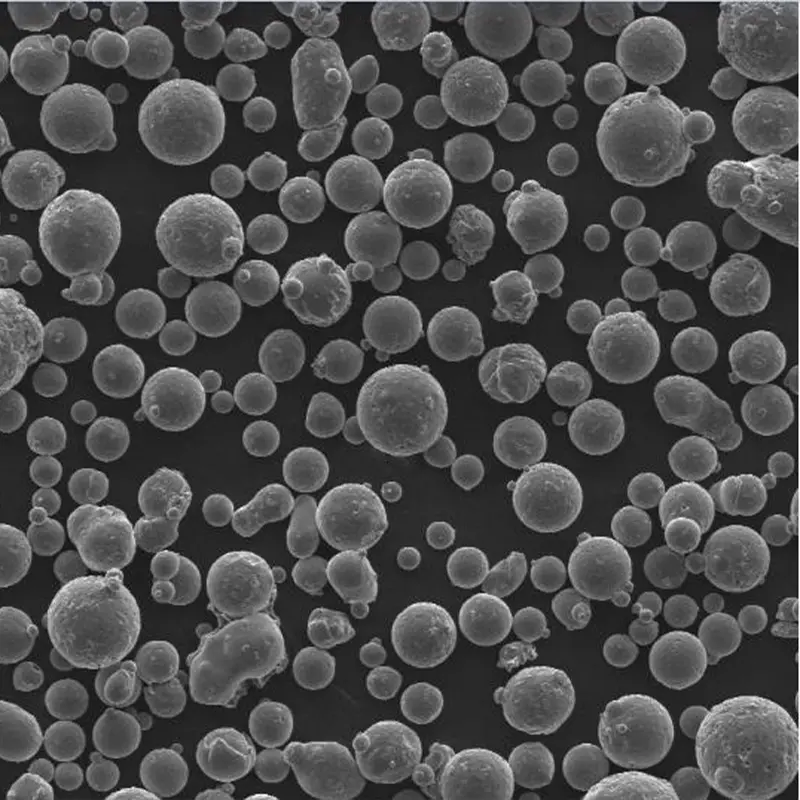

Morphology: Spherical particles

Phase transition point: Varies by alloy formulation and micron-level dimensions

Mass density: 2.699g/cm³ (alloy-dependent)

Volatile components: Non-emissive

Incompatibilities: Avoid exposure to aqueous solutions, corrosive chemicals, and electrostatic environments

Product series: 6xxx, eg.,6013,6061,6063,6092

Product particle size: 0~75µm, 8~10µm, 18~20µm, 15~53µm, 0~25µm, 20~63µm, 20~30µm, 50~150µm

Container loading: 16-18MT per 20'FCL

Packaging options: 25kg/160kg/200kg steel containers with palletization

Distribution channels: Multimodal transportation solutions

Annual throughput: 1,000 metric tons

Lead time: 60-90 days including DG certification

Compliance:

Quality control system: GB/T19001:2016 /ISO9001:2015

Environment control system: GB/T 24001:2016 /ISO14001:2015

Quality Assurance:

ICP-OES analysis for raw material purity verification

Laser particle sizing for gradation control

Hygroscopicity monitoring through moisture analyzers

Gas element quantification via dedicated oxygen detectors

Application:

Primarily employed in aluminum matrix composite (AMC) fabrication

Process characteristics:

Sealed-phase atomization with integrated classification and homogenization processes ensures consistent particle morphology and chemical stability. The final product exhibits low mass density, optimized heat transfer efficiency, exceptional structural integrity, and anti-abrasion performance.

For technical specifications, please contact: info@hnjwx.com

Field:

Consumer electronics

Mechanical parts

Nuclear industry

Heating dissipation

Additive manufacturing

For 6061 alloy powder Example:

| Si | Cu | Mg | Cr | Fe | Mn | Zn | Ti | Co | Al | |

| Detection value | 0.45 | 0.21 | 1.12 | 0.15 | 0.10 | ≤0.01 | 0.02 | ≤0.01 | <0.01 | Margin |