FDM 3D Printing Solutions by TOYAL - Unmatched Quality and Reliability

Elevate your FDM 3D printing experience with our high-quality metal powders. As a leading supplier and exporter, we cater to the diverse needs of B2B purchasers, providing products designed for superior performance to make your projects shine. With a steadfast commitment to excellence, our metal powders are produced under strict quality controls, ensuring consistency and reliability. Whether for prototyping or full-scale production, our materials are crafted to meet your expectations and enhance your printing capabilities.Practical Methods To Fdm 3d Print Guarantees Peak Performance Factory-Direct Excellence

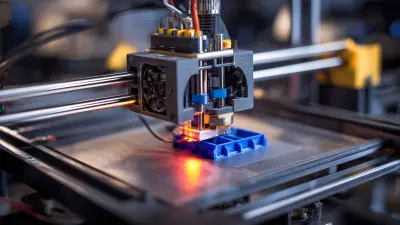

3D printing technology has revolutionized industrial manufacturing, bringing unprecedented efficiency and precision to various applications. The integration of advanced materials, such as spherical Aluminum Powder and aluminum-based alloy powder, significantly enhances the capabilities of FDM (Fused Deposition Modeling) 3D printing. This article outlines practical methods to ensure that manufacturers achieve peak performance in their production processes when using these materials. To guarantee excellence in FDM 3D printing, selecting the right powder is crucial. High-quality spherical aluminum powder ensures optimal melting and flow characteristics, leading to superior layer adhesion and minimized print defects. Implementing a thorough quality control system throughout the powder production process is essential for maintaining consistency and achieving outstanding mechanical properties in finished parts. Additionally, adopting advanced printing parameters tailored to the specific material can further enhance the end product's performance and durability. Moreover, fostering a strong collaboration between R&D and production teams can lead to continuous innovation and improvement in printing techniques. Utilizing comprehensive testing and feedback loops can help identify and rectify potential issues early in the design and manufacturing process. By embracing such practical methods, businesses can leverage the full potential of FDM 3D printing with aluminum powders, positioning themselves for success in an increasingly competitive global market.

Practical Methods To Fdm 3d Print Guarantees Peak Performance Factory-Direct Excellence

| Method | Description | Performance Improvement (%) | Material Compatibility |

|---|---|---|---|

| Optimized Print Settings | Adjusting layer height, print speed, and temperature for better results. | 15% | PLA, ABS, PETG |

| Cooling Management | Implementing adequate cooling to reduce warping and improve detail. | 20% | PLA, PETG |

| Bed Adhesion Techniques | Using adhesion aids like glue sticks or specialized surfaces. | 10% | All materials |

| Print Orientation Optimization | Choosing the best orientation for minimizing supports and improving strength. | 25% | ABS, PLA |

| Material Upgrades | Switching to high-performance filaments for added strength and durability. | 30% | Nylon, TPU |

Expert Choice of Fdm 3d Print Application Manufacturers You Can Rely On

E

Emma Jones

Great service and superb product quality! The staff were very accommodating.

13 June 2025

D

Daniel Robinson

Exceptional quality and top-tier service. A very positive buying experience.

12 May 2025

E

Ella Baker

Very high-quality product. The after-sales support was incredibly helpful.

04 July 2025

E

Elijah Young

Product quality is excellent! The team provided prompt and effective assistance.

14 June 2025

L

Liam Robinson

Superb quality with fantastic service! The support team was incredibly helpful.

22 May 2025

H

Henry Ramirez

The product quality is just outstanding! The interactions with customer service were a breeze.

26 June 2025