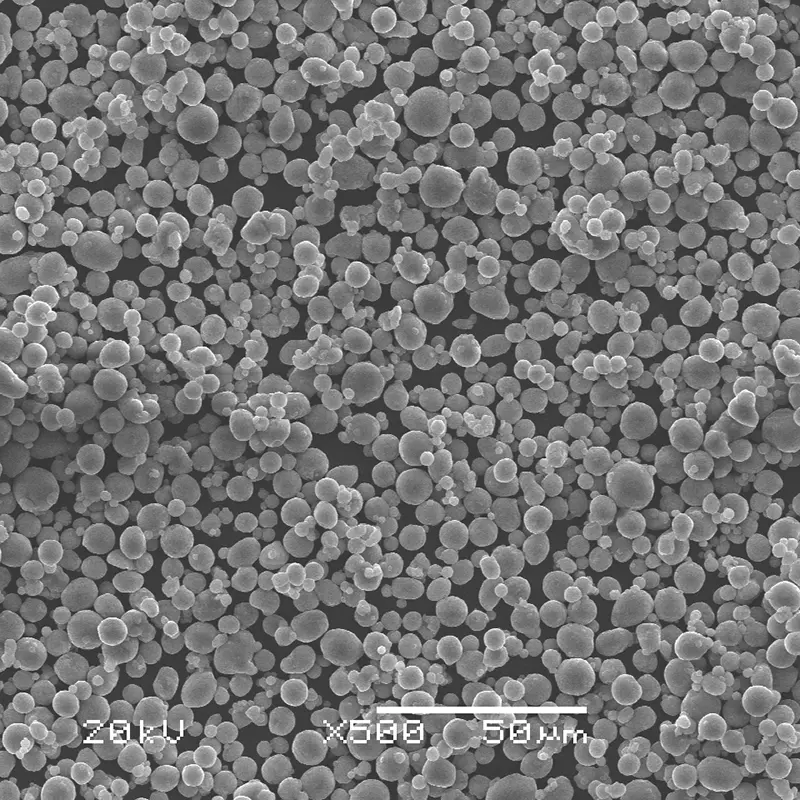

Fabricated Aluminum powder for thermal fillers

It was operated by a single independent system. During the production process, it is controlled by strict controlling method to keep the particle size distribution and consistent appearance; It can control the particle size from the plant, and it is acceptable to do customization as per customer’s requirement on the powder.

Particle size: 1~2µm, 5~6µm, 8~10µm,9~11µm, 13~15µm,15~17µm, 19~21µm, 26~29µm, 30~33µm, 40~50µm, 60~70µm, 100µm

Packaging conditions: 25Kg/Iron drum, 160Kg/Iron drum, 200Kg/Iron drum with pallet

Volume: 12.8 tons, 16 tons, 18 tons(Per 20FCL)

Transportation: By road, by air or by sea

Capacity: 8,000 tons annually

Delivery time: 2~3 months including EL application and inspection

Compliance:

Quality control system: GB/T19001:2016 /ISO9001:2015

Environment control system: GB/T 24001:2016 /ISO14001:2015

Quality Assurance:

ICP for testing incoming impurities of aluminum ingot

Laser diffraction testing machine for testing particle size

Oxygen content machine for oxygen volume

Thermal conductivity tester

Application:

Thermal management materials including thermal grease, thermal filler, thermal pad, phase change materials, etc.

Field:

Heating electronic components related involving:

Automobile

Consumer products (Laptop, mobile, computer, etc.)

Industrial application

contact US:

If you are interested in any of these products, please feel free to let us know by emailing us at info@hnjwx.com We will be happy to provide you with more detailed information upon receipt of your detailed specifications.