Top DMLs Printing Exporter & Manufacturer for Quality Printing Solutions

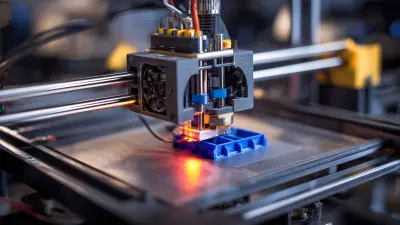

For top-tier Dmls Printing solutions, our DMLS technology guarantees unparalleled precision and durability in every part produced. Recognizing the need for a dependable supplier in the realm of metal 3D printing, Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd stands out with its commitment to exceptional service and high-quality materials. Serving various industries, including aerospace and medical, we provide customized solutions tailored to meet your unique requirements. Collaborate with us and elevate your production capabilities through our state-of-the-art DMLS printing services!

Practical Methods To Dmls Printing Your End-to-End Solution Manufacturer

In today's competitive landscape, manufacturers are increasingly turning to Direct Metal Laser Sintering (DMLS) as a viable method for producing high-performance parts efficiently. To fully harness the benefits of DMLS, it is crucial to partner with a reliable supplier that provides end-to-end solutions. This article outlines practical methods to streamline the process of integrating DMLS into your manufacturing operations, ensuring you can meet evolving market demands. First, choose a supplier with advanced metal powders specifically designed for DMLS applications. The quality and composition of the powder play a vital role in achieving optimal results, such as improved mechanical properties and surface finishes. A partner with expertise in producing spherical aluminum and aluminum-based alloy powders can offer tailored materials that enhance the DMLS process, ensuring compatibility and superior performance. Next, collaborate closely with your supplier during the design and prototyping phases. By utilizing simulation tools and rapid prototyping techniques, you can identify potential issues early in the design process, reduce material wastage, and expedite time-to-market. Additionally, a comprehensive supplier can provide technical support and insights throughout the production cycle, leveraging their experience to enhance your manufacturing capabilities and drive innovation. By implementing these methods, you can maximize the advantages of DMLS while establishing a robust manufacturing foundation.

Practical Methods To Dmls Printing Your End-to-End Solution Manufacturer

| Process Name | Description | Materials Used | Applications | Advantages | Challenges |

|---|---|---|---|---|---|

| Laser Melting | Fuses metal powder with a laser to create dense parts. | Stainless Steel, Titanium, Aluminum | Aerospace, Medical, Automotive | High precision, multi-material capabilities | Cost of materials, longer print times |

| Metal Binder Jetting | Involves binding metal powder with a liquid binder. | Stainless Steel, Bronze | Heavy Equipment, Art, Prototypes | Fast processing, large build volume | Low density, requires additional sintering step |

| Direct Energy Deposition | Melt and deposit material on a substrate using an energy source. | Nickel-based Alloys, Titanium | Repair applications, Tooling | Material flexibility, repair capabilities | Requires skilled operation, complex setups |

| Selective Laser Sintering | Uses laser to sinter powdered material into a solid structure. | Nylon, Polyamide, TPU | Functional Parts, Prototyping | Suitable for complex geometries, strong parts | Post-processing required, surface finish issues |

Top Picks For Dmls Printing Dominates in 2025

K

Kevin Martinez

Top-quality product! The service personnel were attentive and provided fantastic support.

22 May 2025

S

Sophia Young

The quality was exactly what I was looking for. Their support team was exceptional!

22 June 2025

G

Grace Johnson

I am thoroughly impressed! The support team really knows how to assist efficiently.

29 June 2025

H

Henry Carter

The quality is superb! Their customer service staff were very attentive.

07 July 2025

N

Natalie Wilson

This product is a cut above the rest! Excellent attention from customer service.

30 June 2025

A

Anna Perez

Very high-quality product! Their customer service was prompt and highly effective.

01 July 2025