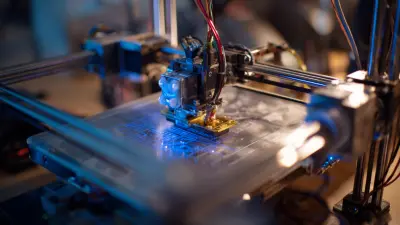

Top DML 3D Printing Companies Driving Innovation in Manufacturing Today

As a leading player in the DMLS 3D printing sector, Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd. recognizes the critical role of high-quality metal powders in additive manufacturing. We are a trusted supplier for renowned manufacturers, providing premium-grade materials essential for precise and efficient printing. Our specialized DMLS 3D print powders are designed to enhance the performance of your 3D printing processes, ensuring they meet the stringent demands of your projects. With a strong commitment to innovation and customer satisfaction, we aim to support your manufacturing goals and help elevate your production capabilities. Join the ranks of many satisfied clients who rely on our exceptional materials. Let's collaborate to advance your projects to new heights!Practical Methods To Dmls 3d Print Winning in 2025 Trusted by Pros

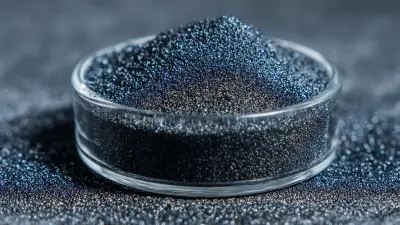

As the world moves towards more advanced manufacturing techniques, the adoption of DMLS (Direct Metal Laser Sintering) 3D printing is becoming increasingly essential for industries aiming for superior quality and performance. In 2025, companies looking to stay ahead must embrace practical methods for harnessing DMLS technology, trusted by professionals across various sectors. The key to success lies in the quality of the metal powders used, particularly spherical Aluminium and Aluminium-based alloy powders, which play a pivotal role in achieving optimal sintering results. To effectively leverage DMLS technology, procurement teams should focus on sourcing high-quality metal powders that enhance the mechanical properties and surface finish of printed parts. Engaging with industry experts and suppliers who specialize in cutting-edge materials ensures that you are not just purchasing products, but also gaining valuable insights into material behavior, compatibility, and best practices for 3D printing processes. By fostering strong partnerships with trusted suppliers, companies can improve their product development cycles, reduce waste, and optimize their production efficiency. As we approach 2025, businesses must prioritize innovation and quality in their manufacturing processes. Emphasizing the importance of high-standard Aluminium powders in DMLS will empower companies to innovate confidently, producing complex geometries and lightweight components that meet the demands of modern engineering. This proactive approach not only enhances product performance but also positions businesses as leaders in the competitive landscape of advanced manufacturing.

Practical Methods To DMLS 3D Print Winning in 2025 Trusted by Pros

| Method | Advantages | Challenges | Recommended For |

|---|---|---|---|

| Laser Power Adjustment | Improves surface finish and reduces defects | Requires precise calibration | Advanced users and professionals |

| Optimal Layer Thickness | Balances speed and detail | May sacrifice strength | General users and hobbyists |

| Post-Processing Techniques | Enhances part performance and aesthetic | Time-consuming | Designers and manufacturers |

| Material Selection | Diverse options for varied applications | Compatibility issues | Industry professionals |

| Simulation and Testing | Predicts performance and reduces errors | Complexity in setup | Engineers and analysts |

Finding Your Perfect Match Dmls 3d Print Factory Now Trending

K

Kevin Martinez

Top-quality product! The service personnel were attentive and provided fantastic support.

22 May 2025

N

Natasha Cox

Truly impressive product quality. The team was helpful and professional throughout.

01 June 2025

A

Alexander Moore

This company exceeded my quality expectations! Customer service was exceptional.

31 May 2025

D

David Lopez

Amazing quality! The support team was knowledgeable and gave me great assistance.

23 June 2025

S

Serena White

The craftsmanship and quality are outstanding! They provided great customer support.

06 June 2025

J

James Fisher

Truly satisfied with the product! The support from the team was exceptional.

05 July 2025