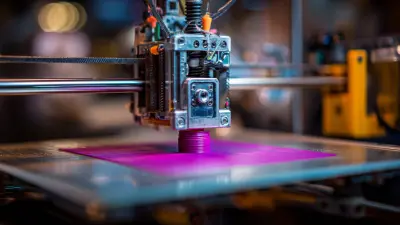

Top DLP 3D Printing Companies in China: Quality Products You Can Trust

As a B2B purchaser, prioritizing reliable and high-quality suppliers is essential. Our DLP 3D printing technology has earned recognition among renowned manufacturers, such as TOYAL. Based in Hunan Ningxiang, we specialize in producing premium metal powders that ensure precision and durability in 3D printing applications. Our DLP 3D printing offers remarkable detail and smooth finishes, making it ideal for both prototyping and end-use parts. With a deep understanding of the unique needs of businesses like yours, our commitment to quality ensures our products align with your specifications. Elevate your manufacturing processes and creative designs with our tailored DLP 3D print solutions. Let's work together to enhance your projects with the precision of our metal powders!Best Way To Dlp 3d Print Your Trusted OEM Partner Trusted by Pros

In the world of 3D printing, especially when dealing with complex designs and high precision requirements, the choice of materials is crucial. One of the most effective methods to achieve superior results in additive manufacturing is through the use of DLP (Digital Light Processing) technology. By leveraging spherical Aluminum Powder and aluminum-based alloy powder, manufacturers can enhance the quality and reliability of their printed components. These materials provide excellent flowability and packing density, allowing for intricate geometries and smooth surface finishes, which are essential for industries that demand top-tier performance. Collaborating with a trusted OEM partner can significantly streamline your production process. Experienced professionals in the field understand the nuances of DLP 3D printing, from material selection to optimizing print settings, ensuring that every project is handled with precision and expertise. A reliable partner not only brings advanced technological capabilities but also possesses a wealth of knowledge about industry standards and compliance, making them invaluable in overcoming challenges and achieving superior product outcomes. As the demand for high-quality 3D printed components continues to rise globally, investing in partnerships with specialized suppliers can set your business apart. By utilizing advanced aluminum powders, you can ensure that your products meet the rigorous standards expected in today's competitive marketplace. This strategic collaboration will enable you to innovate faster, reduce costs, and ultimately drive growth in your operations.

Best Way To Dlp 3D Print Your Trusted OEM Partner Trusted by Pros

| Dimension | Value | Description |

|---|---|---|

| Layer Height | 50 µm | The thickness of each printed layer. |

| Print Speed | 30 mm/s | Speed at which the print head moves. |

| Build Volume | 120 x 70 x 150 mm | Maximum dimensions for printed objects. |

| Materials Used | Photopolymer Resins | Resins used for printing in DLP technology. |

| Post-Processing | Washing and Curing | Steps taken after printing to harden the model. |

| Typical Applications | Prototyping, Jewelry, Dental | Common fields where DLP 3D printing is utilized. |

How To Dlp 3d Print Service Backed by Expertise Outperforms the Competition

S

Samantha Lee

From ordering to delivery, the service was impeccable. The staff was incredibly knowledgeable and helpful!

17 May 2025

C

Chris Harris

Superb quality and exceptional support! The representatives were knowledgeable and very amiable.

31 May 2025

S

Samuel Carter

The quality is unparalleled. The service team handled my queries with utmost professionalism.

22 May 2025

J

John Adams

Truly satisfied with this purchase. Great quality and outstanding support!

19 June 2025

S

Samuel Wright

Fantastic buy! The quality is excellent and the follow-up service was prompt.

12 May 2025

S

Sophie Collins

A great purchasing experience! The quality is impressive and the support team is amazing.

30 May 2025