Top Affordable Suppliers & Factories for Direct Metal Laser Sintering (DMLS) Solutions

As a forefront exporter of Direct Metal Laser Sintering (DMLS) technology, we specialize in providing high-quality metal solutions tailored to diverse industries. Our advanced DMLS processes enable the precise fabrication of intricate geometries, ensuring exceptional durability and performance. At Hunan Ningxiang JiWeiXin Metal Powder Co., Ltd., we leverage cutting-edge metal powders to enhance the sintering process, resulting in superior parts ready for immediate use or further finishing. With years of experience, our factory upholds stringent quality control standards, ensuring each product adheres to international benchmarks. Whether serving small businesses or large enterprises, our dedication to excellence makes us the trusted partner for metal additive manufacturing. Partner with us to elevate your production capabilities and achieve outstanding results with DMLS technology, as your satisfaction remains our priority in driving innovation for your projects.Don't Miss These Direct Metal Laser Sintering Dmls Industry Leaders Trusted by Pros

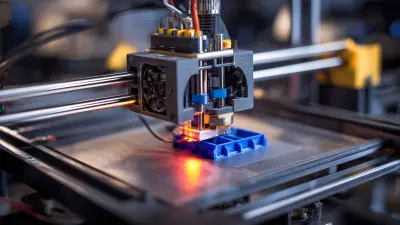

As the demand for advanced manufacturing solutions continues to rise, Direct Metal Laser Sintering (DMLS) has emerged as a pivotal technology in various industries. This cutting-edge additive manufacturing process utilizes high-powered lasers to fuse powdered metals into complex geometries, offering unparalleled design flexibility and rapid prototyping capabilities. For global buyers looking to leverage this technology, understanding the industry leaders in DMLS is crucial to ensuring high-quality outcomes. Among the most reputable players in the DMLS space are companies that specialize in the production of high-quality metal powders. These firms focus on producing spherical Aluminum Powders and aluminum-based alloys, which are essential for achieving optimal sintering results. Their commitment to research and development ensures that they provide not only the best materials but also the technical support necessary to overcome challenges in the DMLS process. By collaborating with these leaders, procurement professionals can access innovative materials that meet rigorous performance criteria and enhance the efficiency of their manufacturing operations. Investing in relationships with trusted DMLS industry leaders can significantly impact production capabilities and overall product quality. As the landscape of additive manufacturing evolves, aligning with experienced suppliers ensures that businesses remain at the forefront of technological advancements and market trends. Don't miss the opportunity to partner with those who have demonstrated excellence in providing reliable metal powder solutions that drive success in the DMLS arena.

Don't Miss These Direct Metal Laser Sintering DMLS Industry Leaders Trusted by Pros

| Company Type | Experience (Years) | Materials Offered | Applications | Certifications |

|---|---|---|---|---|

| Manufacturing | 15 | Titanium, Aluminum, Stainless Steel | Aerospace, Medical, Automotive | ISO 9001, AS9100 |

| Research & Development | 10 | Nickel Alloys, Cobalt Chrome | Dental, Tooling | ASTM F2971 |

| Prototype Services | 12 | Copper, Inconel | Electronics, Defense | ISO 13485 |

| Contract Manufacturing | 20 | Steel, Superalloys | Oil & Gas, Aerospace | NADCAP |

| Custom Solutions | 8 | Aluminum, Titanium | Consumer Products, Industrial | ISO 9001 |

How To Decide Between Direct Metal Laser Sintering Dmls Ahead of the Curve Delivers Unmatched Quality

D

David Smith

I am very satisfied with my purchase. The customer service team provided excellent assistance throughout.

15 June 2025

C

Charlotte King

A fantastic buying experience. The customer service representatives were very knowledgeable.

24 May 2025

A

Ariana Foster

A worthwhile investment! The customer support was both knowledgeable and helpful.

01 June 2025

E

Elijah Young

Product quality is excellent! The team provided prompt and effective assistance.

14 June 2025

J

James Murphy

Very high-quality product! The customer service team is fantastic!

30 June 2025

J

Jason Taylor

A wonderful product! The after-sales staff really knows their stuff.

11 May 2025