Aluminum Metal Powder is becoming increasingly significant in various industries. Its applications span from aerospace to additive manufacturing. According to a report by MarketsandMarkets, the global aluminum powder market size is projected to reach USD 1.2 billion by 2025. This highlights the growing demand for Aluminum Metal Powder.

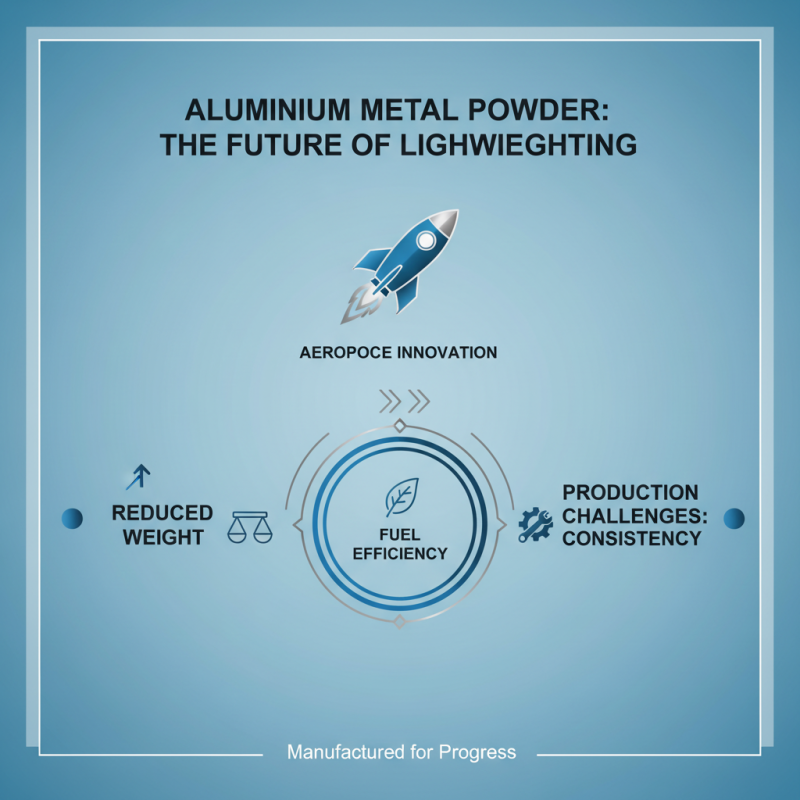

In the aerospace sector, Aluminum Metal Powder contributes to lightweight structures. This enhances fuel efficiency in aircraft. Additionally, in manufacturing industries, it is crucial for producing parts through 3D printing. The material allows for intricate designs, which traditional methods cannot achieve easily. However, challenges like oxidation can hinder performance, requiring careful handling.

Moreover, its use in pyrotechnics and coatings showcases versatility. Nevertheless, not all usage scenarios yield optimal results. Some processes may lead to waste or subpar quality. Hence, understanding how to use Aluminum Metal Powder effectively is essential for maximizing its benefits.

Aluminum metal powder is a versatile material used in various industries. Its properties make it ideal for numerous applications. This powder is lightweight and has a fine particle size. Its high thermal conductivity and low density are significant advantages. This combination allows it to act as an excellent heat conductor in many products.

When used in metalworking, aluminum powder can improve the strength of materials. It enhances the mechanical properties of composites. However, not all aluminum powders perform equally. Some might have impurities that affect their quality. It’s essential to test the powder before use. This can prevent unexpected failures during production.

In the world of additives, aluminum powder is common in paints and coatings. It provides a reflective surface that increases durability. Still, one must be cautious. Wrong particle sizes can lead to inconsistent finishes. As a result, careful selection and testing are crucial before incorporating aluminum powder into any application. This helps in achieving the desired results while avoiding potential drawbacks.

Aluminum metal powder finds use in several industries. It is lightweight and has good conductivity. This makes it ideal for various applications, from construction to electronics. In the construction sector, it is often mixed with concrete. This enhances strength while reducing weight. It can also improve moisture resistance in building materials.

In the realm of 3D printing, aluminum powder plays a crucial role. It allows for the creation of intricate designs that are both durable and lightweight. The powder can be applied in additive manufacturing processes, enabling unique shapes that traditional methods cannot achieve. However, handling aluminum powder requires caution. Fine particles can be hazardous if not properly managed.

In the automotive industry, aluminum powder is used in coatings. These improve the appearance and durability of vehicles. The reflective properties of aluminum enhance aesthetic appeal. Yet, achieving the right balance in formulation can be challenging. It requires testing to determine the best mix for performance and looks. The versatility of aluminum powder is clear, but attention to detail is essential for optimal results.

When working with aluminum metal powder, preparation and handling are crucial for achieving optimal results. Always use appropriate personal protective equipment, such as gloves and masks. This powder is highly flammable. Ensure that your workspace is free from sparks or open flames. Utilize a well-ventilated area or a fume hood to avoid inhaling fine particles.

Storing aluminum powder requires careful consideration. Keep it in a cool, dry place. Use airtight containers to prevent moisture absorption. Moisture can lead to clumping, which affects performance. Familiarize yourself with safety data sheets (SDS) for proper risk assessments. Handle the powder gently, as excessive force can create dust clouds.

If spills occur, act quickly. Use a damp cloth to clean. Avoid sweeping, as this can release particles into the air. Remember that aluminum powder can pose risks if mishandled. Reflect on your processes regularly. Continuous learning enhances safety and efficiency in using this versatile material in different applications.

| Application | Preparation Method | Handling Guidelines | Safety Precautions |

|---|---|---|---|

| Aluminum Powder Coatings | Mixing with resins and solvents | Use a well-ventilated area and wear a mask | Avoid inhalation and contact with skin |

| Aluminum in Pyrotechnics | Blending with oxidizers | Store in a cool, dry place | Handle with care; avoid sparks |

| Aluminum in Additive Manufacturing | Powder recycling and sieving | Use PPE and keep area clean | Minimize dust formation |

| Thermal Insulation | Mixing with insulating agents | Follow mixing ratios accurately | Ensure adequate ventilation |

| Metal Matrix Composites | Incorporation into metal matrices | Use gloves when handling | Store in a stable environment |

When handling aluminum metal powder, safety is paramount. This fine powder can be reactive, especially in certain environments. According to industry reports, dust from aluminum powder poses inhalation risks. Proper ventilation is essential. Always wear appropriate protective gear, including masks and gloves. The Occupational Safety and Health Administration (OSHA) recommends a maximum permissible exposure limit of 15 mg/m3 for total dust.

In addition, aluminum metal powder can cause fires if not stored correctly. Store it in a cool, dry place, away from combustible materials. Use non-sparking tools when transferring this powder. Industry experts note that aluminum dust can ignite in the presence of an ignition source, leading to severe accidents. Regular training on these safety measures can drastically reduce risks.

Make sure to have a safety data sheet (SDS) accessible. An SDS provides critical information about handling, storage, and emergency measures. However, even with precautions, incidents can happen. Reflect on your processes. Are safety protocols being followed strictly? Regular audits of safety practices may highlight areas needing improvement.

This chart illustrates the distribution of aluminum metal powder usage across various industries. Aerospace and automotive applications dominate its use, highlighting the demand for lightweight materials in these sectors.

Aluminum metal powder is increasingly popular in various industries. Its lightweight properties make it ideal for aerospace applications. Manufacturers use it to reduce overall weight and improve fuel efficiency. This innovation, however, can present challenges in production consistency.

In the automotive realm, aluminum powder is found in brake pads and engine components. It enhances performance and reduces emissions. Yet, achieving the right mixture is essential. An incorrect balance may lead to premature wear or reduced efficiency. This leaves engineers with room for improvement and reflection.

Beyond transportation, aluminum powder plays a crucial role in additive manufacturing. It is used to create intricate designs and prototypes. This method allows for creativity but also raises questions about durability. Some products may not withstand harsh conditions. Companies must analyze these risks closely.