Aluminum Bronze Powder is gaining traction for various industrial applications due to its unique properties. The market for aluminum bronze is projected to surpass $1 billion by 2025, driven by increased demand in maritime and aerospace sectors. This copper-aluminum alloy exhibits excellent corrosion resistance and high strength, making it ideal for challenging environments.

Utilizing Aluminum Bronze Powder requires an understanding of its properties and applications. The powder can be used in coatings, additive manufacturing, and new metal formulations. Despite its advantages, users must consider its cost and processing challenges. It is essential to use the right techniques for optimal results and to reflect on potential drawbacks in application methods.

Adopting Aluminum Bronze Powder can lead to innovative solutions, but awareness of limitations is crucial. Companies must invest in proper training and equipment. There is significant potential for growth in sectors demanding durable and efficient materials. As industries evolve, Aluminum Bronze Powder may play a pivotal role in shaping future applications.

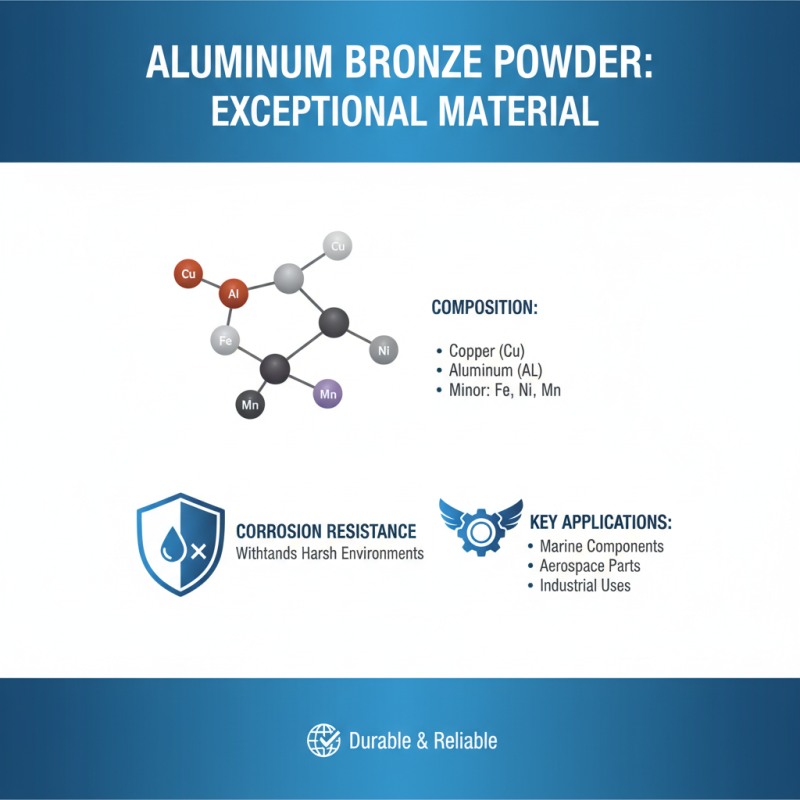

Aluminum bronze powder is a valuable material known for its unique composition. It typically contains copper, aluminum, and small amounts of iron, nickel, or manganese. This blend contributes to its exceptional properties. Aluminum bronze powder has excellent corrosion resistance. It withstands harsh environments and retains its integrity over time. Many industries use it for various applications, such as in marine components and aerospace parts.

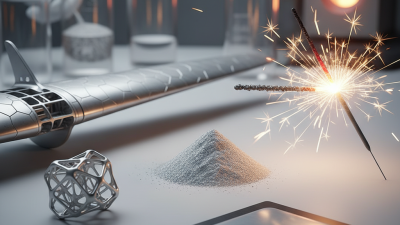

The powder's thermal and electrical conductivity are also noteworthy. These characteristics make it useful in electronics and thermal applications. However, using aluminum bronze powder isn't straightforward. The powder must be handled properly to ensure optimal performance. It can be challenging to achieve the right mixture with other metals, impacting the end product's quality.

Additionally, health and safety precautions are necessary. Breathing in fine powder can be harmful. Always use proper protective gear when working with it. The learning curve can be steep for newcomers, causing frustration. Nonetheless, when used correctly, aluminum bronze powder can significantly enhance product durability and performance.

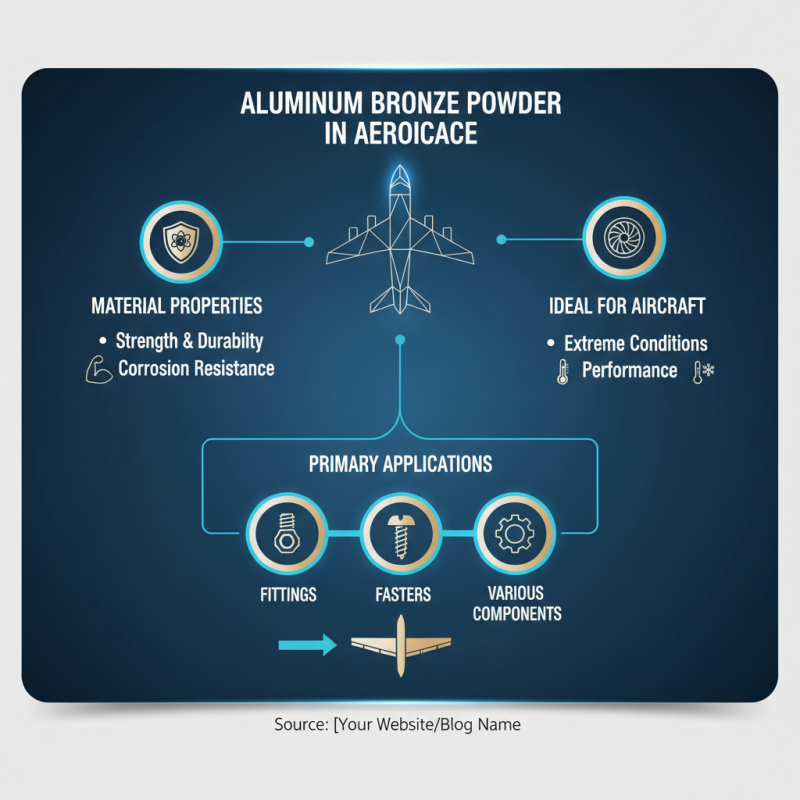

Aluminum bronze powder finds extensive applications in the aerospace industry. This unique material combines strength and resistance to corrosion, making it ideal for aircraft components. One prominent use is in manufacturing various parts, such as fittings and fasteners. These components require durability and performance under extreme conditions.

When using aluminum bronze powder, consider the temperature and pressure requirements. It’s essential to optimize the sintering process for better mechanical properties. Testing the final product for fatigue and strength is vital. These tests ensure that components won't fail during operation.

Tips for effective use: Always conduct thorough research on the alloy composition. Variations can impact performance significantly. Regularly review your processes; small adjustments can lead to substantial improvements. Be prepared to face challenges, such as blending the powder consistently. Continuous refinement is critical for success in aerospace applications.

Aluminum bronze powder plays a crucial role in marine engineering solutions. Its unique properties make it ideal for applications in harsh environments. This powder is known for its corrosion resistance and durability. When applied effectively, it enhances the performance of marine components.

In marine settings, aluminum bronze provides strength against saltwater corrosion. It is often used in shipbuilding and underwater applications. Crews should consider proper mixing techniques to achieve optimal results. Poor mixing may lead to uneven properties in the final product. This can compromise strength and longevity.

Tips: Always test a small batch before full-scale application. This ensures that the properties meet the project requirements. Regular maintenance of tools and equipment is essential. Contaminants can affect the quality of the mixture. Reliability is key; trust your observations. If something seems off, it probably is.

Utilizing aluminum bronze powder can be challenging but rewarding. Each application has unique needs. Finding the right formulation might take time. However, the payoff in performance can be significant. Remember, patience and precision can lead to superior outcomes.

Aluminum bronze powder is gaining traction in the automotive industry. This material boasts remarkable strength and corrosion resistance. According to a recent market analysis, the demand for aluminum bronze in automotive applications is projected to grow by 8% annually through 2025. These statistics underline the powder’s rising significance.

Automakers appreciate aluminum bronze powder for its lightweight properties. A reduction in weight translates to improved fuel efficiency, a primary concern for manufacturers. This powder also enhances parts like bearings and bushings, extending their lifespan significantly. Some studies show that components made from this alloy can increase durability by 30% compared to traditional materials.

Despite its advantages, challenges remain. The cost of aluminum bronze can be higher than alternatives. Companies must weigh this against potential savings on maintenance and replacement. In some applications, consistency in powder quality varies, leading to performance uncertainty. Ongoing research aims to address these issues, refining production methods to ensure reliability and affordability.

Aluminum bronze powder is widely used in various applications, but safety is paramount when handling it. Proper storage and handling practices protect both users and the environment. Always store aluminum bronze powder in a cool, dry place. Use sealed containers to prevent moisture absorption, which can affect its quality.

When handling aluminum bronze powder, it is crucial to wear appropriate personal protective equipment (PPE). Goggles and gloves are essential to avoid direct contact. Dust masks can also help prevent inhalation of fine particles. Ensuring adequate ventilation in your workspace is another key factor. This reduces the risk of inhaling any powder that may become airborne.

Tips: Regularly check storage containers for any signs of damage. This can help prevent accidental spills. Make a habit of washing hands after handling the powder, even if gloves are worn. It's always better to be cautious. Reflect on past experiences to identify areas of improvement in your handling procedure, and don't hesitate to make adjustments for safety.

| Application | Best Practices | Storage Conditions | Safety Measures |

|---|---|---|---|

| Aerospace Components | Ensure uniform particle size for consistent properties. | Store in a dry, cool place away from moisture. | Use appropriate PPE, including gloves and masks. |

| Marine Hardware | Mix thoroughly to prevent segregation. | Keep in sealed containers to avoid contamination. | Follow local regulations for dust control. |

| Electrical Connectors | Use precise dosing to maintain conductivity. | Store in airtight containers away from heat. | Implement fire safety measures in storage areas. |

| Artistic Sculptures | Mix with binders for better adhesion. | Avoid exposure to direct sunlight to prevent degradation. | Use ventilation when working with powder to minimize inhalation. |