Uncoated Aluminum Powder plays a crucial role in various industries. Its unique properties make it a valuable resource. This lightweight material is often used in manufacturing and construction. Companies appreciate its excellent corrosion resistance and conductivity.

In the automotive sector, Uncoated Aluminum Powder enhances lightweight designs. This leads to improved fuel efficiency. In the aerospace industry, this powder helps create durable components, reducing the overall weight of aircraft.

However, industries must consider the limitations of Uncoated Aluminum Powder. For example, its performance can fluctuate depending on the environment. Companies may need to adapt their usage to different conditions. Despite these challenges, its versatility remains evident in numerous applications.

Uncoated aluminum powder serves vital roles in the aerospace industry. Its lightweight nature contributes to improved fuel efficiency. This advantage is crucial for airlines seeking to reduce operational costs. The fine particles of aluminum offer excellent thermal conductivity. This property helps manage heat in various aerospace components.

The powder is often used in advanced manufacturing techniques. For example, it plays a role in 3D printing. This method allows for the creation of complex and lightweight parts. However, ensuring the appropriate particle size and shape is essential. Too large particles can lead to weak structures.

**Tips:** Always consider the application when choosing aluminum powder. Particle size affects strength and weight. Regular quality checks are necessary. Any inconsistencies can impact safety and performance. Collaboration with specialists can enhance the design process. This step ensures optimal use of aluminum powder.

Uncoated aluminum powder has gained traction in automotive manufacturing due to its lightweight and versatile properties. This material helps reduce overall vehicle weight, enhancing fuel efficiency. Cars become more eco-friendly when they consume less fuel. Besides, these powders are used in various coatings and paints. This can boost a vehicle's aesthetic appeal while providing protection against rust.

The use of uncoated aluminum powder isn’t without challenges. For instance, achieving the right consistency in particle size is crucial. If not properly processed, this can lead to uneven application. This inconsistency might impact the overall performance of the vehicle. Additionally, exposure to moisture can affect the powder's quality. Manufacturers need to ensure proper storage conditions, which adds complexity to the production process.

Despite these hurdles, many manufacturers are enthusiastic about using uncoated aluminum powder. Its potential benefits are substantial, though it requires careful management. Overall, the push towards sustainable practices is driving interest in this material. Continued innovation and research could lead to even broader applications in the industry.

This chart illustrates the various applications of uncoated aluminum powder across different industries, highlighting their relative utilization levels.

Uncoated aluminum powder is gaining traction in pharmaceuticals and healthcare products. Its lightweight properties make it ideal for various applications. In drug formulations, it acts as a flow agent. This improves the mixing and granulation process.

Moreover, it aids in the manufacturing of medical devices. The fine particles ensure a smooth surface finish. This enhances comfort for patients. The challenge lies in quality control. Maintaining consistent particle size is crucial. This ensures effectiveness in applications.

In topical creams and ointments, uncoated aluminum powder serves as a protective barrier. It contributes to the stability of formulations. Yet, there can be variability in performance. Understanding the reaction with other ingredients is essential. Overall, its role is significant, but it needs careful handling in development.

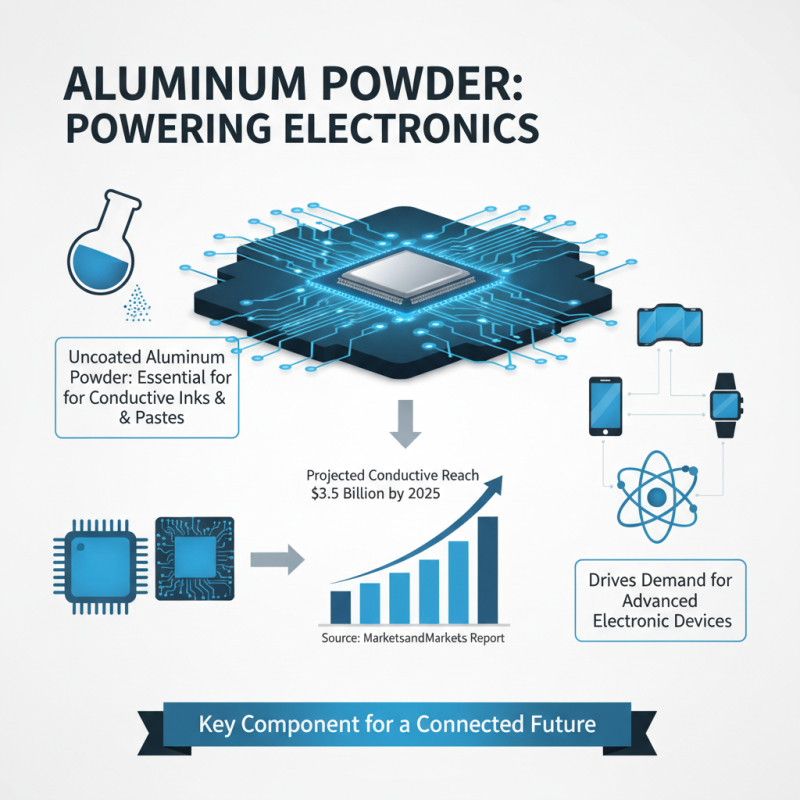

Uncoated aluminum powder plays a crucial role in the electronics and electrical equipment industry. It serves as an essential component in conductive inks and pastes. According to a report by MarketsandMarkets, the global conductive inks market is projected to reach $3.5 billion by 2025. This growth is partly due to the high demand for advanced electronic devices that use aluminum powder.

The lightweight and conductive properties of aluminum powder enhance the performance of electronic components. In applications such as touchscreens, aluminum acts as a functional layer for better conductivity. Recent trends indicate that over 25% of electronic devices now incorporate some form of aluminum-based materials. This integration has led to innovations in miniaturizing electronic devices.

Despite its benefits, challenges remain. The quality of aluminum powder can vary significantly. Not all powders offer the same level of conductivity or consistency. Manufacturers must navigate these variances to meet industry standards. Additionally, environmental concerns around aluminum extraction and processing need addressing as industries strive for sustainability. Balancing performance with ecological responsibility is increasingly important.

Uncoated aluminum powder plays a significant role in the paints and coatings industry. Its unique properties contribute to enhancing product performance. When mixed into paints, it can provide both aesthetic appeal and functional advantages. For instance, it adds a metallic sheen that many find visually appealing. This effect is often used in decorative finishes.

However, achieving the right balance can be tricky. Too much aluminum powder can lead to issues like poor adhesion. It is essential to test formulations to avoid common pitfalls. Experimentation with different ratios can lead to improved results, but meticulous monitoring is crucial. Every mix is an opportunity to learn.

Tips for using aluminum powder: ensure the mixing environment is clean. Even tiny particles can alter performance. Also, consider the application technique; it affects the final appearance. Lastly, store aluminum powder properly to maintain its properties, preventing moisture absorption. Understanding these factors can elevate your coating products to the next level.