In the world of additive manufacturing, the choice of materials plays a crucial role. Among these, 3D printer metal material stands out for its strength and versatility. With advancements in technology, metal 3D printing continues to shape various industries, from aerospace to medical devices.

Selecting the right metal material can be daunting. Different applications require different properties. For instance, some projects may demand high corrosion resistance. Others might focus on thermal stability. Each decision impacts the final product's performance.

Despite the growing options, challenges remain. Not all 3D printer metal materials are suitable for every printer. Print quality can vary significantly based on material type. It's essential to weigh the benefits against the limitations. Thus, understanding the nuances of these materials is key for successful outcomes.

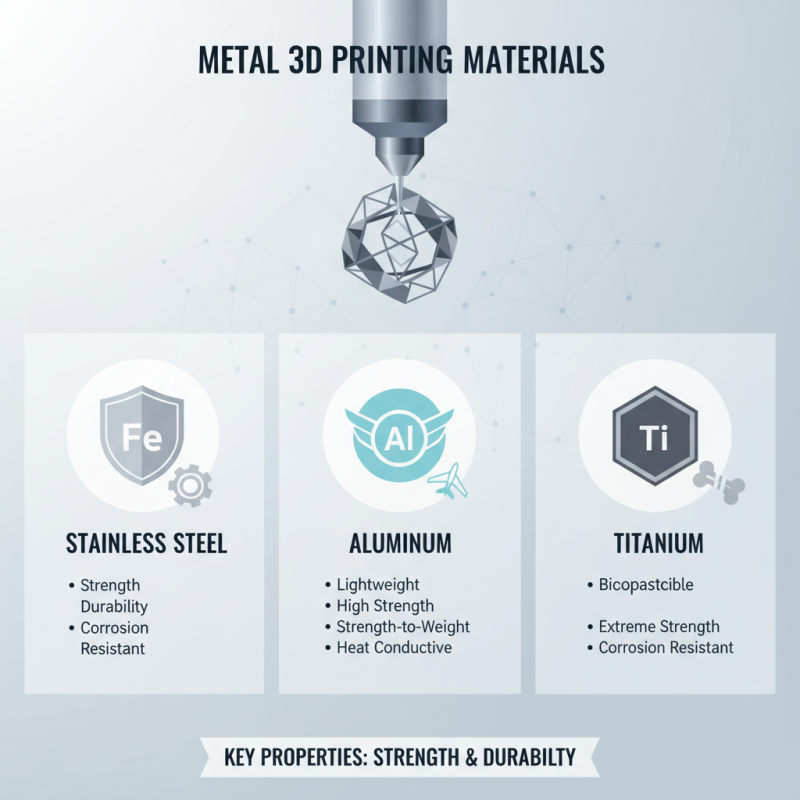

In the world of 3D printing, metal materials play a crucial role. They are essential for producing sturdy and durable parts. Each metal has unique properties that influence the printing process. Common materials include stainless steel, aluminum, and titanium. These metals are often chosen for their strength and resistance to corrosion.

One tip for selecting metal materials is to consider the intended application. Stainless steel is great for functional parts due to its toughness. Aluminum is lightweight, making it ideal for aerospace applications. Titanium, while more expensive, offers unparalleled strength-to-weight ratios. Understanding the material's properties can lead to better prints.

Not all metal prints are flawless. Issues like warping and poor adhesion can occur. It's essential to monitor the printing environment. Ensure proper heating and cooling during the process. Inspect the finished product regularly. This helps catch imperfections early. Finally, experiment with different materials to find the right fit for your project. Each print is a learning opportunity.

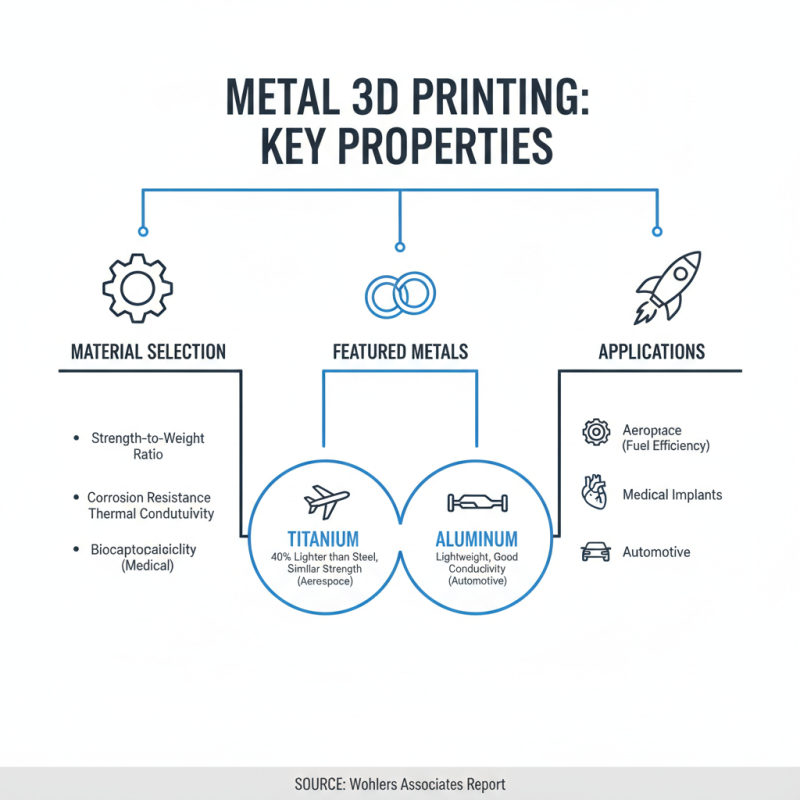

When selecting metal materials for 3D printing, key properties become paramount. Metals like titanium and aluminum shine for their strength-to-weight ratios. According to a report by Wohlers Associates, titanium parts can be 40% lighter than steel while maintaining similar strength. This is crucial in applications such as aerospace, where weight savings translate to fuel efficiency.

However, not all metals provide similar performance in 3D printing. Some may warp significantly during the cooling phase. The thermal properties of metals dictate how they behave under heat. For instance, stainless steel has a higher thermal conductivity, leading to better print quality. Yet, the same property can create challenges in achieving fine details. Achieving optimal layer adhesion often requires precise temperature control.

Furthermore, surface finish quality is another vital property. Some metals yield smoother surfaces than others, impacting post-processing needs. Reports indicate that while titanium can achieve excellent finish quality, it often requires extensive finishing steps. Additionally, printability varies widely among materials. Some may need specific print settings, which can complicate production timelines. This complexity highlights the ongoing need for research and development in metal 3D printing technologies.

When it comes to 3D printing, choosing the right metal material is crucial. The right choice influences the strength, durability, and finish of the final product. Some materials, such as aluminum, are lightweight and easy to work with. Others, like titanium, offer exceptional strength but can be challenging to print. The printing process itself can affect the quality of the material used.

Stainless steel is another popular choice. It's known for its corrosion resistance and strength. However, achieving smooth surfaces can require post-processing efforts. Some users may encounter unexpected warping during the printing phase. This can lead to wasted materials and time. Using nickel alloys can enhance properties but often comes with a steep learning curve. It’s important to experiment to find the best settings for each specific material.

Copper and bronze materials offer unique aesthetic qualities, often providing a distinctive finish. These can be tricky to print, as they may require specialized nozzle temperatures. Users often find that achieving consistency is more challenging than with standard materials. Each metal brings its own set of advantages and obstacles, making careful selection essential for each project.

When it comes to 3D printing with metal, understanding the mechanical properties of materials is crucial. Each metal has unique traits that affect performance. For instance, titanium alloys are known for high strength-to-weight ratios. They are effective for aerospace applications, but their cost can be prohibitive. Stainless steel, on the other hand, offers a balance of strength and corrosion resistance. However, it might not meet the rigidity needed for certain engineering applications.

Aluminum alloys provide excellent thermal conductivity and low density. They are often used in automotive parts. But their strength can vary significantly across different alloys. Research shows that while aluminum shows promise, its performance under stress can be inconsistent. Additionally, copper alloys exhibit superior thermal and electrical conductivity. They excel in specific applications, but their ductility often limits their use in 3D printing.

A comparative study cited that tungsten carbide presents an interesting case. It has high wear resistance but is challenging to print. The mechanical properties are impressive, but the overall success rate is low. Each material comes with advantages and limitations. Engaging with these trade-offs is essential for optimal results in 3D printing projects. Adjusting parameters and understanding these materials allows more refined applications in various industries.

When selecting metal materials for 3D printing, several key factors deserve careful consideration. First, the melt temperature is crucial. Materials like titanium require higher temperatures than aluminum. A study from the Additive Manufacturing Industry reported that over 60% of professionals find temperature adaptability challenging. This challenge can lead to inconsistent prints and operational downtime.

Another important aspect is the mechanical properties of the metals. Stainless steel offers excellent strength but can be hard to process. In contrast, aluminum is lighter and easier to work with but may not meet strength requirements in all applications. A recent analysis found that 45% of engineers faced issues with strength discrepancies during post-processing. Finally, surface finish matters. A rough surface can lead to improper fit in final products. Awareness of these nuances is vital. Understanding specific applications and environments is essential to making informed choices.