Aluminum Bronze Powder is a versatile material used in various projects. It boasts excellent strength and corrosion resistance. Artisans and engineers appreciate its golden hue and unique properties. Whether crafting jewelry or creating intricate components, this powder is valuable.

When employing Aluminum Bronze Powder, understanding its characteristics is crucial. It flows well and can bond effectively. However, achieving the desired results requires some practice. This material can be tricky, particularly for newcomers. It's easy to underestimate the importance of proper techniques.

Each project presents its own challenges and learning opportunities. Mistakes may happen along the way, but they lead to growth. With careful experimentation, you can unlock the true potential of Aluminum Bronze Powder. Embrace the journey, as every attempt brings you closer to mastery.

Aluminum bronze powder is a valuable material in various applications. It consists mainly of copper and aluminum, which gives it unique properties. This alloy is known for its excellent corrosion resistance and strength. It has a gold-like appearance, making it visually appealing for artistic projects.

When using aluminum bronze powder, it's essential to consider its particle size. Finer powders can provide better coverage but might be more difficult to work with. Coarser powders are easier to handle but may not give the desired finish. Mixing techniques can also impact the final result. Incorrect ratios might lead to uneven color distribution, which can be frustrating.

The melting point of aluminum bronze varies with composition but typically ranges from 900 to 1,050°C. This can make casting and molding a challenge for beginners. Inconsistent heating can lead to defects in the final product. Always test small batches first. This can help you understand how the material behaves under different conditions. Learning from these experiences can lead to better outcomes in future projects.

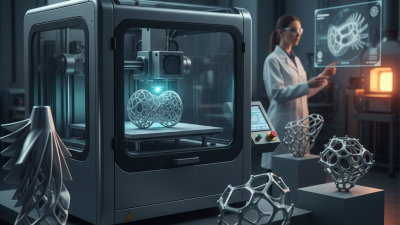

Aluminum bronze powder has various applications across multiple industries, thanks to its unique properties. In marine environments, it resists corrosion effectively. It can be used in boat components and offshore platforms. The durability of aluminum bronze makes it a go-to material for parts that face harsh conditions.

In the automotive sector, aluminum bronze powder is increasingly popular. It is utilized in manufacturing gears and bearings. These components benefit from the powder's excellent wear resistance. However, the fine particles can be tricky to work with. Ensuring consistent quality is essential to avoid failures in critical applications.

In the art world, aluminum bronze powder serves as a medium for creating metallic finishes in sculptures. Artists appreciate its rich golden hue and malleability. Mixing it with different binders can produce varied textures. Yet, the mixing process can be unpredictable. Artists might find that they need to experiment to achieve the desired effect. The beauty of aluminum bronze powder lies in its versatility, but also its challenges.

When preparing aluminum bronze powder for your projects, careful consideration is essential. Start by assessing the particle size. Finer powders may blend easily but can also agglomerate. This could lead to uneven distribution in your mixture. Consider using sieving techniques to achieve the desired consistency.

The level of oxidation can also impact the powder's performance. Ensure your materials are fresh and store them properly to maintain quality.

Humidity is a critical factor too. Aluminum bronze powder can absorb moisture, affecting its flowability and reactivity. Keep your workspace dry and use desiccants if necessary. Mixing techniques matter. Inadequate mixing can lead to clumps or inconsistencies. Experiment with various methods to find what works best for your specific application. You might realize some methods yield better results than others.

Lastly, safety cannot be overlooked. Always wear appropriate protective gear when handling powders. Spills can create hazards, and the dust can be harmful if inhaled. A clean, organized workspace aids in safety and efficiency. Reflect on these points often. Each project is an opportunity to improve your preparation and handling of aluminum bronze powder.

When working with aluminum bronze powders, proper mixing and handling are crucial.

Always wear protective gear. Dust can be harmful when inhaled. Use a mask and goggles,

even if the workspace seems clean. Store powders in sealed containers. This keeps moisture out and maintains their quality.

Mixing requirements vary. Use proper mixing techniques to ensure even distribution. Avoid using excessive force,

as it can lead to clumping. While a blender may seem efficient, it can generate heat and alter properties.

Hand mixing can be labor-intensive, but it can also yield better results

if done carefully. Remember to check for consistency.

Handling aluminum bronze requires a bit of practice. Be mindful of static electricity;

it can cause powders to fly. Sometimes, the powders may not mix thoroughly, resulting in uneven textures.

Adjusting techniques may be necessary. Experiment with different methods. It's okay to make mistakes;

learning helps improve future projects.

When working with aluminum bronze powder, safety must be a top priority. This fine metal powder can pose serious health risks if not handled correctly. Always wear protective gear. Gloves, goggles, and masks are essential. Even small particles can irritate the skin or lungs. Mishaps can occur, leading to unwanted exposure.

Ensure proper ventilation in your workspace. A fume hood or an open area can help minimize inhalation risks. If you notice any unusual symptoms while using the powder, stop immediately. It’s better to pause and assess the situation than to continue recklessly. Clean spills promptly using a vacuum designed for metal powders. Water can create sludge, which may spread contamination further.

Storage also requires attention. Keep aluminum bronze powder in a cool, dry place, away from any ignition sources. Sealed containers will help prevent accidental exposure. Misplacing a container can cause confusion later. Not following these safety measures can lead to accidents that are easily avoidable. Think critically about your work environment and procedures.