Aluminium Flash Powder is a widely used component in various pyrotechnic applications, known for its unique properties that enable rapid ignition and bright flashes of light. According to the Global Pyrotechnics Market Report published by Industry Insights, the demand for Aluminium Flash Powder has seen a steady increase, with projections estimating a compound annual growth rate (CAGR) of 5.2% over the next five years. This growth is largely driven by the expanding fireworks industry and its application in special effects for film and television.

However, the use of Aluminium Flash Powder requires stringent safety precautions to mitigate risks associated with its flammable nature. Dr. Emily Carter, a leading expert in pyrotechnic safety, emphasizes the importance of handling this material with care, stating, "Proper training and adherence to safety protocols are crucial when working with Aluminium Flash Powder to ensure safe and successful outcomes." As the popularity of crafting and pyrotechnics grows among hobbyists and professionals alike, it is imperative to impart essential safety tips and guidelines to facilitate responsible usage of Aluminium Flash Powder in various projects. By promoting awareness and education around safe handling practices, we can significantly reduce the potential risks associated with this powerful material.

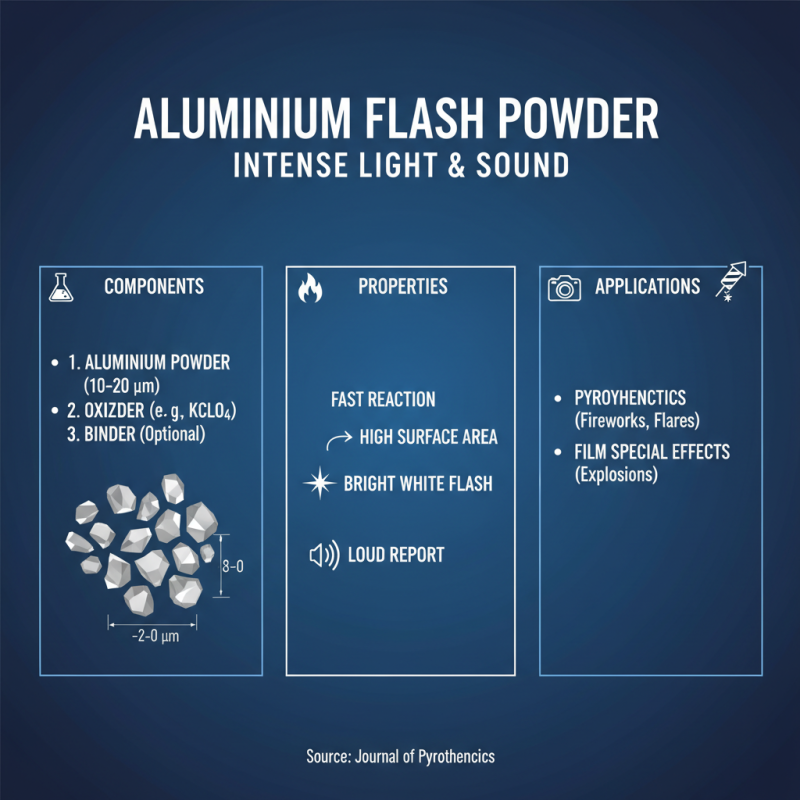

Aluminium flash powder, primarily composed of fine aluminum particles combined with oxidizers like potassium perchlorate, is renowned for its intense combustion and bright white flash. The composition typically includes three components: aluminum powder, an oxidizing agent, and sometimes a binder. According to the Journal of Pyrotechnics, the aluminum particles usually range from 10 to 20 micrometers in size, significantly influencing the reaction rate and the visual effects produced. These particles, due to their large surface area to volume ratio, enhance the powder's reactivity, resulting in a bright flash and a loud report, making them valuable in both pyrotechnics and special effects in the film industry.

Understanding the properties of aluminium flash powder is crucial for safe handling and effective use. It has a relatively low ignition temperature, around 180-200°C, and can be highly sensitive to impacts or static discharge, necessitating stringent safety protocols during storage and application. A report from the National Fire Protection Association (NFPA) highlights that improper handling can lead to hazardous situations, emphasizing the importance of using appropriate containers that are both non-conductive and withstand high temperatures. Additionally, best practices advocate for using in well-ventilated areas to prevent the accumulation of potentially explosive gases, thus ensuring user safety while taking advantage of aluminium flash powder's remarkable visual effects.

When working with aluminium flash powder, safety must be the top priority. This highly reactive material, often used in pyrotechnics and special effects, requires careful handling to prevent accidents. One of the key precautions involves wearing appropriate personal protective equipment (PPE). Make sure to don safety goggles, gloves, and dust masks to protect against any accidental inhalation or contact with the skin.

In addition to PPE, it's crucial to work in a well-ventilated area free from flammable materials. Flash powder can ignite easily, so maintaining a clean workspace helps mitigate risks. Store aluminium flash powder in a cool, dry place, preferably in containers specifically designed for hazardous materials. This minimizes the chance of accidental ignition and ensures the material is kept in optimal conditions.

Lastly, always follow best practices for mixing and using aluminium flash powder. Use non-sparking tools and avoid generating static electricity. When preparing mixtures, do so in small batches to control any reactions. By adhering to these safety tips, you can ensure a safer experience in your projects involving aluminium flash powder.

Proper storage of Aluminium Flash Powder is crucial for ensuring safety and maintaining its effectiveness in various projects. According to a report from the American Institute of Chemical Engineers, about 30% of accidents involving reactive powdered materials can be attributed to improper storage practices. To mitigate risks, storing Aluminium Flash Powder in a cool, dry place is essential. It should be kept away from direct sunlight and potential sources of ignition, as elevated temperatures can increase the reactivity of the powder and lead to hazardous situations.

Moreover, the packaging plays a significant role in maintaining the integrity of Aluminium Flash Powder. Utilizing containers made from non-reactive materials, such as polyethylene or glass, can help to prevent contamination and degradation of the powder. The National Fire Protection Association emphasizes the importance of labeling storage containers clearly, indicating the material inside and any related hazards. This ensures that anyone handling the powder is aware of its properties and can take appropriate precautions. Implementing these best practices can significantly reduce the risks associated with storing Aluminium Flash Powder and support safer working conditions in various applications.

| Storage Method | Temperature Range (°C) | Container Type | Shelf Life (months) | Safety Precautions |

|---|---|---|---|---|

| Cool, dry place | 15 - 25 | Airtight, non-static container | 12 | Avoid moisture, protect from heat |

| Refrigerated storage | 2 - 8 | Glass container with lid | 24 | Ensure airtight seal, handle with care |

| Room temperature | 20 - 22 | Plastic container, preferably HDPE | 6 | Keep away from ignition sources |

| Under inert gas atmosphere | -20 - +20 | Sealed metal containers | 36 | Specialized handling required |

When working with aluminium flash powder, safety should always be your top priority. Mixing and using flash powder requires meticulous attention and adherence to best practices to ensure a smooth and successful project. Always work in a well-ventilated area to minimize the risk of inhaling any fine particles. Using appropriate personal protective equipment, such as gloves, goggles, and a dust mask, is essential to shield yourself from potential hazards during mixing and application.

One important tip is to measure your components accurately before combining them. Utilizing an electronic scale can help provide precise measurements, which is crucial for achieving the desired effects. Mixing should be done slowly and carefully; avoid vigorous stirring that can lead to accidental ignition. Instead, use a gentle folding motion to blend the materials thoroughly while keeping the mixture in a controlled and safe environment.

Additionally, store your aluminium flash powder in a cool, dry, and secure location away from any heat sources or flammable materials. Label the containers clearly and keep them out of reach of unauthorized personnel. Regularly check for any signs of degradation or clumping, which may indicate that the material should be disposed of safely. By following these best practices, you can enjoy a safer experience while working with aluminium flash powder in your projects.

In managing the risks associated with aluminium flash powder, thorough preparation and an understanding of emergency response procedures are crucial. According to a report from the National Fire Protection Association (NFPA), flash powders are classified as explosive materials that can pose serious hazards if handled improperly. In the event of an accident, prompt and effective response can significantly mitigate injuries and damages.

Emergency response procedures should include immediate evacuation of the area to minimize exposure to potential explosive effects. It is vital to alert local emergency services and provide them with detailed information about the materials involved. A study by the U.S. Chemical Safety Board emphasizes the importance of having a well-established emergency plan, which includes specific roles for personnel in case of a flash powder incident. Additionally, access to fire extinguishing agents suitable for metal fires—such as Class D extinguishers—is essential for a quick response.

Tips for safe handling of aluminium flash powder include wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and flame-resistant clothing. Always work in a well-ventilated area to reduce the risk of dust accumulation, which can lead to accidental ignition. Furthermore, ensure that storage facilities comply with industry standards, such as those laid out in the Occupational Safety and Health Administration (OSHA) regulations, to prevent potential mishaps during storage and transportation.