Aluminum Black Powder is a versatile material widely used in various industries. Experts emphasize the importance of safety when handling it. Dr. Emily Carter, an industry leader, stated, "Understanding the properties of Aluminum Black Powder is essential for safe application."

In the world of metal powders, Aluminum Black Powder stands out. It has applications in fuels, pyrotechnics, and more. Its fine particles provide unique benefits but also pose risks. Improper handling can lead to accidents. Quick health hazards often arise from inhalation or skin contact.

Proper storage is critical. Experts recommend keeping it in a cool, dry place. Ventilated areas help minimize dust accumulation. Reflecting on best practices is needed. Familiarity with safety data sheets can aid understanding. Each application demands a tailored approach. Safety should never be overlooked when dealing with Aluminum Black Powder.

Aluminum black powder is a finely divided metallic powder, primarily used in a variety of applications. It consists of aluminum particles that have been treated to enhance their reactivity. This powder is known for its light weight and energy density. It appears as a dark gray or black substance, often with a shiny appearance. These properties make it valuable in pyrotechnics and propellants.

When using aluminum black powder, safety is paramount. The material can easily ignite when exposed to heat or sparks. Therefore, storing it in a cool, dry place is crucial. Using appropriate containers can minimize risks. Proper personal protective equipment, such as gloves and goggles, is essential while handling the powder.

Although aluminum black powder has various uses, it poses challenges. Its reactivity can lead to unintended accidents. Careful measurements and procedures are necessary to ensure safety. Users often find that understanding the powder's properties can lead to better practices. Regular training and education remain vital to mitigate risks associated with its use.

Aluminum black powder is widely used in various sectors, including manufacturing and construction. However, its handling requires caution. Safety precautions are crucial. Many industry reports highlight that aluminum powder can pose serious hazards if not managed properly. Ignoring safety can lead to accidents.

Always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and respirators. Dust particles can easily become airborne. Inhalation of fine aluminum dust may cause respiratory issues. Studies show that long-term exposure can result in conditions like pneumonitis. Therefore, using dust control measures is vital.

Work in a well-ventilated area. Proper airflow helps disperse any build-up of harmful particles. Keep the work area clutter-free to prevent accidents. Store aluminum black powder in a cool, dry place away from incompatible materials. Simple lapses in storage can lead to dangerous situations. Before starting any project, conduct a thorough risk assessment. Understanding the potential dangers can make a significant difference.

Aluminum black powder finds diverse applications across various industries, each demanding specific safety measures. The aerospace sector uses it in lightweight composite materials. According to a recent report from the Institute of Aerospace Studies, nearly 40% of new composite materials utilize aluminum black powder for enhanced performance. This increases fuel efficiency yet requires careful handling to avoid combustion risks.

In the pyrotechnics industry, aluminum black powder is a key component. Its reactivity is both a benefit and a challenge. The National Fire Protection Association highlights a significant number of incidents involving improper storage practices. Small quantities can ignite, causing dangerous explosions. Proper ventilation and specific storage conditions are essential, yet often overlooked.

The construction industry also leverages aluminum black powder in lightweight concrete formulations. This application can reduce material weight by 20%, facilitating easier transport. However, working with finer powders poses respiratory hazards. Safety data indicates that workers may underestimate inhalation risks, leading to potential health issues over time. Awareness of these challenges is crucial for effective safety management.

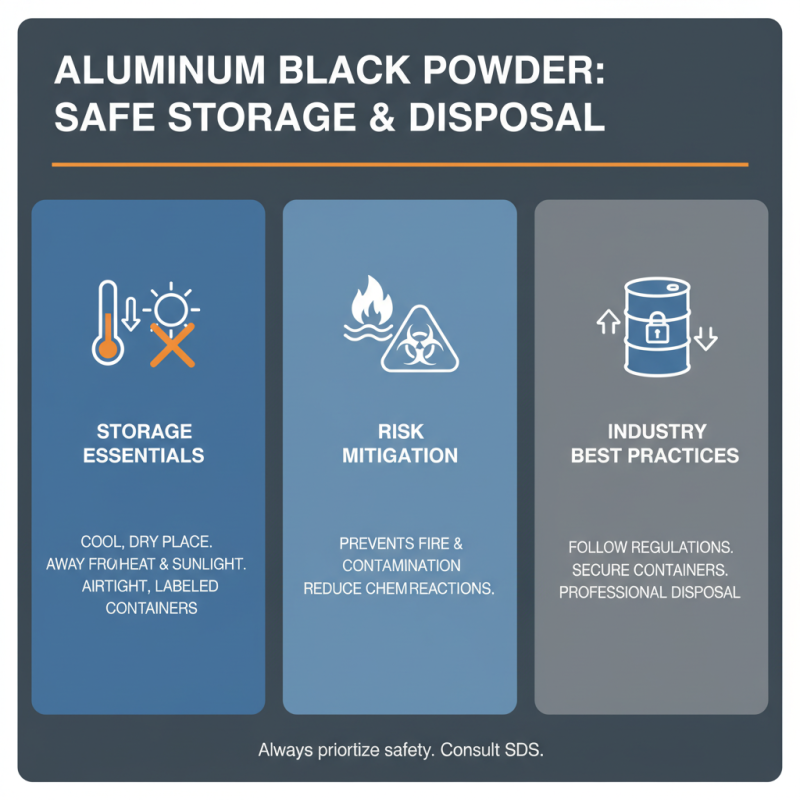

When working with aluminum black powder, safe storage and disposal practices are paramount. Proper storage can mitigate risks associated with fire and contamination. Maintain aluminum black powder in a cool, dry environment. Keep it away from heat sources and direct sunlight. Containers should be airtight and clearly labeled. According to industry reports, improper storage can increase the likelihood of chemical reactions.

Tips: Always check for leaks in containers. Regularly inspect storage areas for signs of wear or damage.

Disposal of aluminum black powder must follow local regulations. Never discard it carelessly. A common method is to contact a hazardous waste disposal service. This ensures safety and compliance. According to environmental data, improper disposal can have grave consequences, affecting both soil and water quality.

Tips: Create a disposal plan before starting your project. Consult local guidelines regularly. Always wear protective gear when handling aluminum black powder to avoid unnecessary exposure.

Working with aluminum black powder requires caution. Although it has many applications, it poses potential hazards. The powder can be highly reactive, especially when mixed with other substances. This reactivity can lead to fires or explosions if not handled properly. Proper safety measures are crucial to mitigate these risks.

Always wear appropriate personal protective equipment. This includes gloves, goggles, and a face mask. Keep the work area well-ventilated to reduce inhalation risks. Store aluminum black powder in a cool, dry place away from any sources of ignition. Use non-sparking tools to prevent unintended reactions.

Tip: Regularly inspect storage containers for any signs of damage. Be conscious of humidity and temperature, as they can affect stability. If spills occur, clean them promptly with appropriate techniques. A well-prepared setup can minimize dangers significantly.

Mistakes can happen, even to experienced users. Reflect on your methods and seek advice if unsure. Continuous learning and adaptation are vital in safely using aluminum black powder. Stay updated on best practices to enhance safety in all applications.