Aluminum Metal Powder is gaining significant attention across various industries. According to recent industry reports, the demand for aluminum powders is expected to grow at a CAGR of 6% through 2027. This growth is driven by their applications in aerospace, automotive, and additive manufacturing. Experts highlight the unique properties of aluminum powder, such as lightweight, high strength, and corrosion resistance.

Dr. Emily Chen, a renowned expert in advanced materials, states, "Understanding the nuances of Aluminum Metal Powder can lead to innovations that redefine efficiency." These insights underscore the importance of mastering effective usage techniques. However, many professionals overlook crucial aspects, leading to suboptimal results.

For instance, improper storage and handling of aluminum powder can result in contamination. This compromises the material's quality and performance. Therefore, considering these factors is vital for maximizing its effectiveness. The tips presented in this guide will address these challenges. They aim to enhance your proficiency in employing Aluminum Metal Powder for your projects, ultimately paving the way for greater success in your endeavors.

Aluminum metal powder is a versatile material used in various industries. Its lightweight and high strength make it an excellent choice for applications like aerospace and automotive manufacturing. According to a recent market study by Grand View Research, the global aluminum powder market is projected to reach USD 5.5 billion by 2028, reflecting its growing demand.

In the field of additive manufacturing, aluminum powder is essential. It contributes to creating complex geometries with ease. However, the powder can be prone to oxidation, affecting its performance. Handling techniques should minimize exposure to moisture and contaminants. Moreover, achieving the right particle size distribution is critical. Some studies suggest that 80% of the powder's performance relies on its particle morphology.

While aluminum powder has promising applications, challenges remain. The right milling process must be chosen. If not, it can lead to undesirable properties. In terms of safety, aluminum dust can be hazardous. Proper precautions are essential to prevent health risks. Understanding these factors is key to maximizing the effectiveness of aluminum metal powder in various applications.

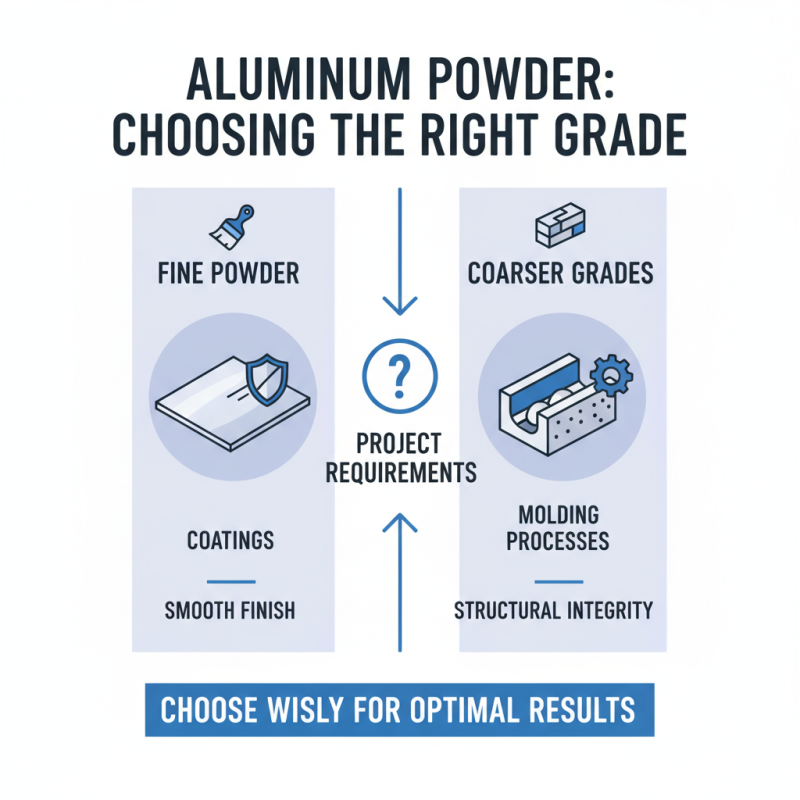

Choosing the right grade of aluminum powder is crucial for your project. Various grades exist, each serving a unique purpose. Fine powders are often used for coatings, providing a smooth finish. Coarser grades may be better for molding processes, offering structural integrity. It's important to understand the specific requirements of your application before making a choice.

Consider the particle size and morphology of the aluminum powder. Finer particles can enhance reactivity and performance but can also increase the risk of dust and handling issues. A balanced approach is needed. The purity level is another factor; higher purity generally means a better final product but often comes with increased cost.

Some projects may require a blend of different grades to achieve the desired outcomes. Testing small batches can provide insights into performance. Don't hesitate to adjust your choice based on feedback. Mistakes do happen, and they can lead to unexpected results. Embrace them as learning opportunities to refine your approach to using aluminum powder effectively.

When handling aluminum metal powder, safety is paramount. The powder can be highly reactive, especially when it becomes airborne. According to a study by the National Fire Protection Association (NFPA), aluminum dust can lead to explosive conditions in certain environments. Ensuring proper ventilation is crucial. You should always work in a well-ventilated space to minimize dust accumulation.

Using personal protective equipment (PPE) is essential. This includes gloves, goggles, and respirators. The American Industrial Hygiene Association (AIHA) recommends using N95 respirators when working with fine powders. Dermal exposure can lead to complications, including skin irritation. Keep your workspace clean and free of unnecessary materials that can accumulate dust.

It’s also important to store aluminum metal powder properly. Containers should be airtight and non-combustible. Improper storage can lead to moisture absorption, which increases reaction risks. Pay attention to your surroundings. If you notice any unusual reactions, stop immediately and reassess your techniques. Regular training and readiness to adapt to changing situations can enhance safety. Remember, safety is an ongoing commitment, not just a checklist.

When blending aluminum metal powder, achieving consistency is crucial. Start by using a clean and dry container. Residue from previous materials can affect the mixture. Consider using a sifter to eliminate clumps in the powder. This step can prevent uneven mixtures and help with flowability.

Mixing techniques matter. A simple method involves using a spatula or a mixer designed for powders. Mix slowly at first. Rapid movements might create dust. Dust can compromise safety and quality. It’s essential to maintain a balanced approach when mixing. Sometimes, the best mixes come from trial and error.

Adding a small amount of binding agent may help in achieving a better blend. Yet, be cautious with the quantity. Too much can ruin the properties of aluminum powder. Always record your process, noting what works and what doesn’t. Reflection on these trials will improve your technique over time. This journey involves learning from imperfections and fine-tuning your methods.

Aluminum metal powder requires specific storage and maintenance to retain its quality. Keep the powder in a cool, dry place. Exposure to moisture can lead to clumping, affecting its usability. Use airtight containers for better protection. Label each container with the date of purchase. This helps to track freshness.

Check the storage area often. Look for signs of moisture or contamination. If any is detected, it’s crucial to evaluate the powder’s condition. When working with aluminum powder, maintain a clean workspace. Poor hygiene can introduce contaminants. Avoid using aluminum powder near open flames. It can be a fire hazard if not handled properly.

Regularly inspect your inventory. Discard any clumped or discolored powder. This ensures you work with effective material. While aluminum powder is versatile, improper storage can lead to significant waste. Reflect on your methods and adapt as needed. Good storage practices enhance performance and safety.

| Tip Number | Tip Description | Storage Recommendation | Maintenance Advice |

|---|---|---|---|

| 1 | Keep Aluminum Powder Dry | Store in a cool, dry place away from moisture. | Regularly check for any signs of moisture. |

| 2 | Use Airtight Containers | Use sealed containers to prevent contamination. | Inspect containers for proper sealing. |

| 3 | Label Storage Containers | Clearly label containers with contents and date. | Update labels when contents change. |

| 4 | Avoid Direct Sunlight | Store away from direct sunlight to reduce heat exposure. | Monitor storage area temperature regularly. |

| 5 | Maintain Proper Airflow | Ensure good ventilation in storage area. | Check for airflow blockages regularly. |

| 6 | Use Gloves When Handling | Wear gloves to avoid contamination from oils. | Replace gloves if they become damaged. |

| 7 | Avoid Mixing with Other Materials | Do not mix with other powders to maintain purity. | Check for cross-contamination regularly. |

| 8 | Dispose of Waste Properly | Follow local regulations for disposal. | Review disposal guidelines periodically. |

| 9 | Regularly Check for Damage | Inspect storage containers for damage. | Replace damaged containers immediately. |

| 10 | Educate Staff on Safety Protocols | Provide training on safe handling and storage. | Schedule regular safety refreshers. |