In the world of metalworking, Aluminum Flux Powder plays a crucial role in ensuring successful projects. According to Dr. Emily Carter, a renowned expert in metallurgical engineering, "Using Aluminum Flux Powder correctly can significantly enhance the quality of your welds." This statement underscores the importance of mastering its application.

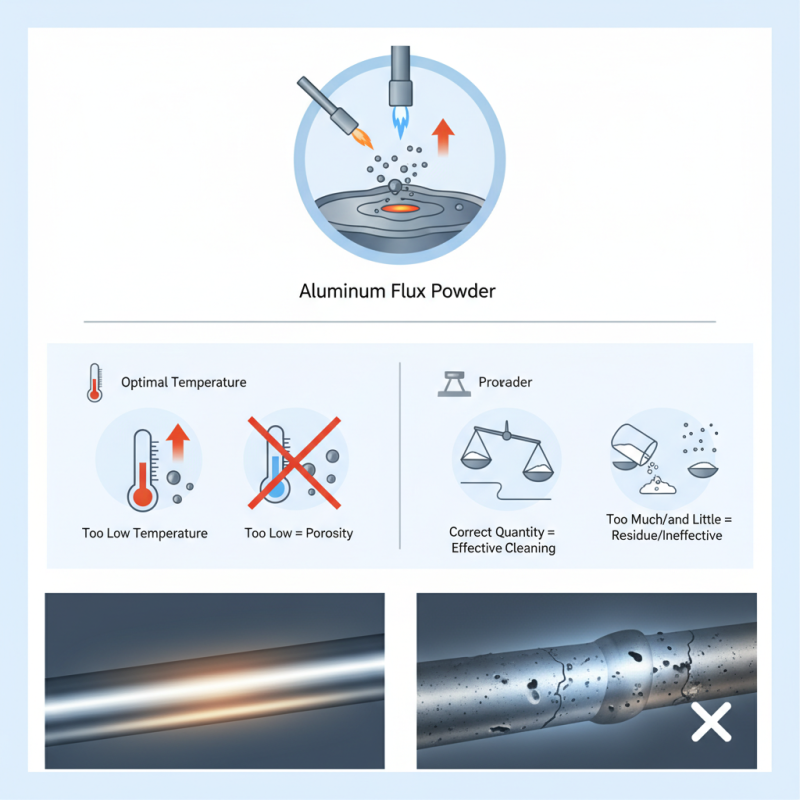

Understanding Aluminum Flux Powder is essential for achieving optimal results. Its chemical properties allow it to remove impurities during the melting process. However, improper usage can lead to issues like porosity or ineffective cleaning. For instance, if the temperature is too low, the powder might not bond correctly, causing defects. Many users overlook this detail, leading to unsatisfactory outcomes.

Moreover, some professionals may underestimate the importance of the right quantity. Too much flux can create excessive residue, while too little can hinder the flux's effectiveness. Each project requires careful consideration. Awareness of these nuances can make the difference between a successful weld and a flawed one. Embracing these challenges can help users fully realize the potential of Aluminum Flux Powder in their work.

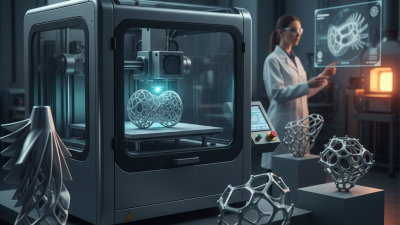

Aluminum flux powder is a blend of finely milled aluminum particles and various chemical additives. It serves as a crucial component in metalworking projects. The addition of flux powder improves the melting process by lowering the melting point of aluminum. This allows for smoother casting and reduces oxidation.

The properties of aluminum flux powder depend on its composition. The particle size can influence its effectiveness. Smaller particles often offer better flow and reaction rates, but they can be harder to handle. A balance must be struck between fine and coarse powders. Additionally, mixing ratios can vary, leading to different results in projects. Experimenting with these variables is essential for achieving optimal melting conditions.

Achieving the desired outcomes can be tricky. Inconsistent results may lead to flawed castings. Ensuring uniform application is key. Over-application can cause excess slag, making cleanup challenging. It’s vital to observe and adjust techniques accordingly. Regularly assessing the effectiveness of the powder in your work ensures improvements and better outcomes over time. Remembering to note what works and what does not can guide future projects.

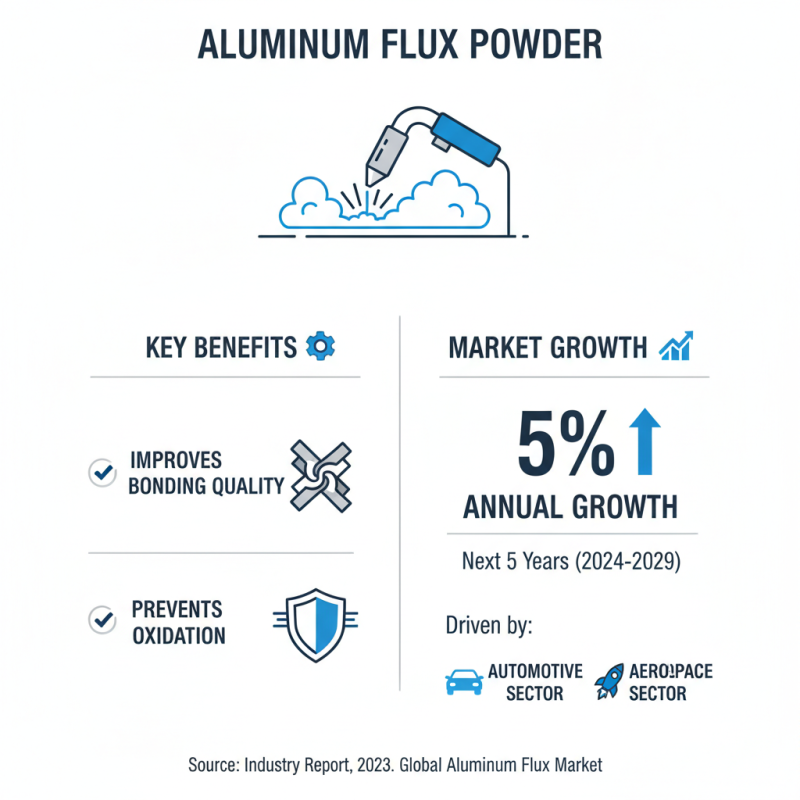

Aluminum flux powder is a crucial material in metalworking and welding projects. This powder improves the bonding quality and effectively prevents oxidation during metal welding processes. According to a recent industry report, the global aluminum flux market size is expected to grow by 5% annually over the next five years. This growth is driven by the increasing demand in the automotive and aerospace sectors.

In welding, aluminum flux powder enhances arc stability and reduces spatter. It creates a protective layer that allows for cleaner welds. However, its application must be precise. Using too much can lead to contamination. Even experienced welders may struggle with correct dosage.

Tips: Always start with a small amount. Gradually increase based on your observation. Monitor results closely. Adjust your approach as needed.

In metalworking, aluminum flux powder serves as a vital ally. It helps in processes like brazing and soldering. Yet, misunderstanding its properties can lead to poor outcomes. Some may expect instant results when applying this powder. In reality, practice and adjustment are key to achieving the desired quality. Proper training and research can help prevent common mistakes, leading to smoother project executions.

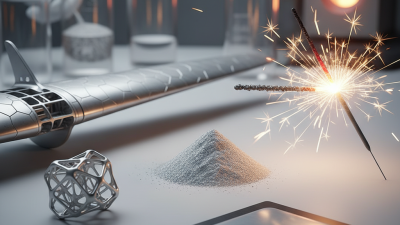

Preparing aluminum flux powder for projects can be straightforward, but attention to detail is crucial. Start with a clean workspace. Ensure all tools and equipment are free from moisture. This prevents the flux from clumping.

Next, measure the aluminum powder accurately. Using too much or too little can affect your project's outcome. Add the powder to your mix gradually. Stir it well to ensure even distribution. An uneven mix can lead to poor results. Keep track of your measurements for future reference.

**Tips:** Work in small batches when possible. This helps maintain control over the process. If you notice clumps forming, don’t panic. Just use a sieve to break them up. Also, take notes on your mixing ratios. This is essential for replicating successful outcomes. Don’t hesitate to adjust your approach based on previous projects. Trial and error is often part of refining your technique.

Aluminum flux powder is essential in many industries, especially metalworking. Proper handling and storage can greatly influence project outcomes. The Occupational Safety and Health Administration (OSHA) notes that aluminum dust can pose respiratory hazards. Thus, personal protective equipment (PPE) is vital. Workers should wear masks, goggles, and gloves to minimize exposure.

Storing aluminum flux powder should occur in a cool, dry place. Moisture can lead to clumping, making it less effective. The National Fire Protection Association (NFPA) provides guidelines for storing flammable materials, such as keeping them away from heat sources. Containers must be airtight to preserve their properties. A dedicated, labeled storage area helps prevent accidental mixing with incompatible substances.

For best results, always check the expiration date. Using expired powder can affect performance. It’s recommended to use the powder within six months of opening. Documentation, like a Material Safety Data Sheet (MSDS), can provide vital safety information. Regular training sessions for workers can reinforce safety standards. Even minor lapses in protocol can lead to significant setbacks. Reassessing these practices regularly can enhance overall project integrity.

| Aspect | Best Practice |

|---|---|

| Storage Temperature | Store in a cool and dry place, ideally between 15°C to 25°C (59°F to 77°F). |

| Container Type | Use airtight, moisture-proof containers to prevent contamination. |

| Handling Safety | Always use gloves and a mask when handling to avoid inhalation and skin contact. |

| Mixing Ratio | Follow recommended guidelines for the specific alloy to achieve optimal results. |

| Application Method | Apply evenly and at the correct temperature for best performance. |

When working with aluminum flux powder, safety should be your top priority. This powder can be reactive and cause harmful fumes if mishandled. Always wear appropriate protective gear, such as gloves, goggles, and masks. Ensure that your workspace is well-ventilated. Avoid open flames or sparks nearby, as they can ignite the material.

One tip is to keep a fire extinguisher handy. Accidents can occur, and being prepared can prevent serious damage. Additionally, store aluminum flux powder in a cool, dry place, away from moisture. This prevents clumping and ensures it remains effective for your projects.

Remember, improper handling can lead to unplanned consequences. If you accidentally spill some powder, do not sweep it up. Instead, use a damp cloth to avoid creating dust. It’s crucial to think twice about your actions while handling these materials. Safety should guide every step in your project.