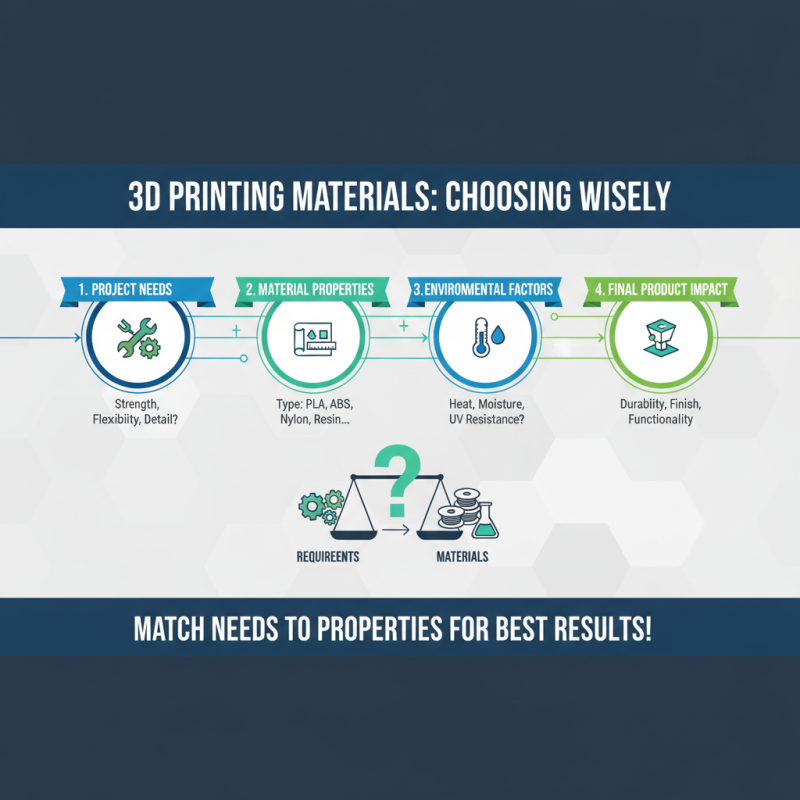

Choosing the right 3D printing materials can be daunting. Each project has unique requirements. The material selection directly impacts the final result. Strength, flexibility, and durability are key factors to consider. You may feel overwhelmed by the options available.

Plastic, metal, and resin each have distinct characteristics. For instance, PLA is great for beginners, but not ideal for high-stress applications. On the other hand, nylon offers flexibility and resilience but can be challenging to print. It’s crucial to evaluate your project's specific needs.

Don't forget about the environment. Some materials are more eco-friendly than others. This can influence your decision. In the end, experimentation may lead to unexpected results. Be prepared for a learning curve. Thoughtful choices will enhance your 3D printing experience.

When choosing 3D printing materials, understanding the diverse options is crucial. Common categories include thermoplastics, resins, and metals. According to industry reports, thermoplastics hold around 60% of the market share in 3D printing materials. Among these, PLA and ABS are popular choices for beginners. They are user-friendly and generally available.

It’s essential to consider your project’s requirements. For sturdy prototypes, ABS is favorable for its strength. On the other hand, PLA is better for environmentally friendly projects due to its biodegradable properties. However, PLA can warp under high temperatures. Always test the material before committing to a large print.

Tip: Keep a small inventory of commonly used materials for quick access. This saves time and helps in rapid prototyping.

As 3D printing evolves, new materials emerge. Nylon, for example, is gaining traction for its flexibility and strength. Yet, it can be challenging to print due to warping. Understanding each material’s characteristics allows for better decision-making. Reflect on how these attributes impact your project's outcome.

Choosing the right 3D printing materials is crucial for project success. Evaluating material properties such as strength, flexibility, and durability can greatly enhance the final outcome. Strong materials are key for functional parts. If a component needs to withstand stress, selecting a high-strength option is essential. Some materials, however, may be too rigid, causing potential issues in applications requiring bending or movement.

Flexibility is another vital aspect. Some projects need parts that can flex without breaking. For instance, certain designs demand elastic materials. This is where balancing strength and flexibility becomes essential. It’s important to test how materials behave under different conditions. Sometimes, what seems flexible on paper may not hold up in real-life uses.

Durability cannot be overlooked, either. A material might perform well initially but could degrade over time. External factors, like UV exposure, can affect longevity. Finding a durable material is not always straightforward. It requires research and sometimes tedious experimentation. Be prepared for some trial and error. The right choice may not be obvious at the beginning, and project requirements can shift, forcing you to reconsider your options.

When selecting 3D printing materials, cost and availability are critical factors. Prices can vary widely across regions and suppliers. In 2022, the global 3D printing materials market was valued at approximately $1.4 billion and is projected to reach $4.7 billion by 2027. This rapid growth indicates increasing interest and potential, but it also encourages careful consideration of budgeting.

Availability can be a hurdle. Certain materials may be easy to find in some locations but scarce in others. For instance, thermoplastics like PLA and ABS are generally more accessible compared to specialty materials like nylon or metal powders. Data from industry reports show that about 40% of users face challenges finding the right materials for their projects. This scarcity can lead to project delays. Additionally, shipping costs should be considered, especially for remote areas.

Researching suppliers in advance is advisable. Consider local distributors for quicker access and reduced costs. Digital platforms can enhance options but may involve longer lead times. Balancing quality and expense is often a tightrope walk. Pricey materials may promise superior results, but they can inflate budgets. If initial findings suggest low availability or high costs, it might be worth revisiting project specifications or exploring alternative materials.

| Material Type | Cost per kg ($) | Availability | Best Use Cases |

|---|---|---|---|

| PLA | 25 | Widely available | Prototyping, Art, Toys |

| ABS | 30 | Commonly available | Functional Parts, Models |

| PETG | 35 | Readily available | Durable Parts, Food Containers |

| TPU | 50 | Less available | Flexible Parts, Wearables |

| Nylon | 40 | Moderately available | Strong Parts, Mechanical Components |

When selecting 3D printing materials, sustainability and environmental impact are crucial. Many popular materials, like PLA and ABS, have different ecological footprints. For instance, PLA is derived from renewable resources, making it a biodegradable option. According to the Plastics Industry Association, PLA decomposes within 90 to 120 days in industrial composting conditions. However, its production still requires energy and contributes to water consumption.

In contrast, ABS, while being durable, poses more environmental challenges. The manufacturing process emits greenhouse gases. A report from the European Commission states that ABS recycling rates are low, often ending up in landfills. This raises concerns about the long-term impact of using such materials.

Moreover, emerging alternatives like recycled PETG show promise. These materials can significantly lower waste. The World Economic Forum highlights that using recycled plastics can cut down carbon emissions by up to 30%. However, the industry still faces hurdles in scalability and acceptance. Choosing sustainable 3D printing materials requires careful consideration, as not all options are equally environmentally friendly.

This chart illustrates the environmental impact and sustainability ratings of various 3D printing materials based on factors such as biodegradability, carbon footprint, and recycling potential. The values are based on a scale from 1 to 10, with 10 being the most sustainable.

Choosing the right material for 3D printing can be tricky. Each project has unique requirements. Understanding these needs is essential. Different materials have various properties that affect the final product.

For strength, consider using materials like nylon or polycarbonate. They offer high durability. If your project requires flexibility, thermoplastic elastomers are ideal. These materials can bend and stretch without breaking. If the project needs a polished finish, look at PLA or ABS. They can achieve smooth surfaces effortlessly.

**Tips:** Always check material specifications. Each type has different heat resistance and durability. Test samples before committing to a large print. It helps identify potential issues early. Remember, not every material suits every project. Reflection on the requirements will guide your choice. A wrong choice may lead to failures and wasted resources. Constant learning is part of the process.