In recent years, the use of Aluminium Alloy Powder has surged across various industries, driven by its versatility and lightweight properties. According to the latest report by MarketsandMarkets, the global aluminium powder market is projected to reach USD 1.71 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.8% from 2020. This growth is largely attributed to the increasing demand for advanced materials in the aerospace, automotive, and construction sectors. As professionals seek to elevate their projects, understanding how to choose and effectively use aluminium alloy powder has become imperative.

Dr. Emily Harrison, a renowned expert in material science and a leading researcher at the International Aluminium Association, emphasizes the significance of proper selection in her statement: “The right aluminium alloy powder can enhance the material properties of your projects, making them not just lighter but also stronger and more resilient.” This underscores the vital role of aluminium alloy powder in modern engineering and product development. As we delve deeper into the selection criteria and application techniques, this guide aims to equip you with the knowledge necessary to leverage aluminium alloy powder to its fullest potential in your upcoming projects.

Aluminium alloy powder has increasingly become an essential material in modern projects due to its lightweight, strength, and versatility. In various applications, from aerospace to automotive industries, the demand for materials that offer high performance while maintaining manageable weight is critical. Aluminium alloy powders exhibit excellent properties, such as corrosion resistance and thermal conductivity, making them ideal for advanced manufacturing processes like

additive manufacturing (3D printing) and

powder metallurgy.

As projects in 2025 focus more on sustainability and efficiency, the choice of materials like aluminium alloy powder will play a key role in achieving these goals. The ability to recycle aluminium powders contributes to minimizing waste and reducing the carbon footprint of production processes. Furthermore, advancements in powder production methods and alloy compositions continue to enhance the performance characteristics of aluminium alloys, making them suitable for high-stress applications without compromising on quality or safety. This progression signifies a shift in how projects leverage materials to achieve innovative designs and functionalities, ensuring that aluminium alloy powder remains a vital component in various modern engineering applications.

When selecting aluminium alloy powder for projects, it's essential to understand the different types of aluminium alloys and their unique properties. Aluminium alloys can be broadly classified into two categories: wrought and cast alloys. Wrought alloys, such as those from the 6000 series, are known for their excellent corrosion resistance and good workability, making them suitable for applications like construction and automotive components. On the other hand, cast alloys, particularly from the 2000 and 7000 series, offer superior strength and are often utilized in aerospace applications where performance is critical.

According to a report by the Aluminium Association, the demand for aluminium alloys is projected to increase significantly, driven by their lightweight characteristics that contribute to energy efficiency in various industries. In 2025, innovations in alloy compositions are expected to enhance properties such as fatigue resistance and thermal stability. For instance, new developments in 7075-T6 alloys show a remarkable strength-to-weight ratio, making them an attractive choice for high-performance applications. Understanding these properties not only aids in the selection of the appropriate aluminium alloy powder for specific applications but also helps in optimizing the performance and durability of the final product.

| Type of Aluminium Alloy | Typical Use | Composition (%) | Strength (MPa) | Weight (g/cm³) | Corrosion Resistance |

|---|---|---|---|---|---|

| 6061 | Structural Applications | Al: 97.9, Mg: 1.0, Si: 0.6 | 240 | 2.70 | Good |

| 7075 | Aerospace and Military | Al: 90.7, Zn: 5.6, Mg: 2.5 | 570 | 2.81 | Fair |

| 2024 | High-Strength Applications | Al: 90.7, Cu: 4.4, Mg: 1.5 | 470 | 2.78 | Poor |

| 3003 | Cooking Utensils and Chemical Equipment | Al: 96.3, Mn: 1.2 | 130 | 2.73 | Excellent |

When selecting aluminium alloy powder for your projects in 2025, it is essential to consider several critical factors to ensure optimal performance and suitability. Firstly, the specific application of the aluminium alloy powder plays a crucial role in your decision. Different alloys possess distinct mechanical properties, such as strength, ductility, and corrosion resistance. Understanding the requirements of your project—whether it involves 3D printing, aerospace applications, or automotive manufacturing—will guide you in choosing an alloy that meets these demands effectively.

Another important consideration is the particle size and distribution of the alloy powder. The fineness of the powder can significantly influence the flow characteristics and packing density, affecting the overall mechanical properties of the final product. A well-controlled particle size distribution ensures better coverage during the mixing process and contributes to enhanced sintering in additive manufacturing. Additionally, it is advisable to evaluate factors like purity levels and any potential contaminants in the alloy powder, as these can impact the overall performance and durability of your finished goods.

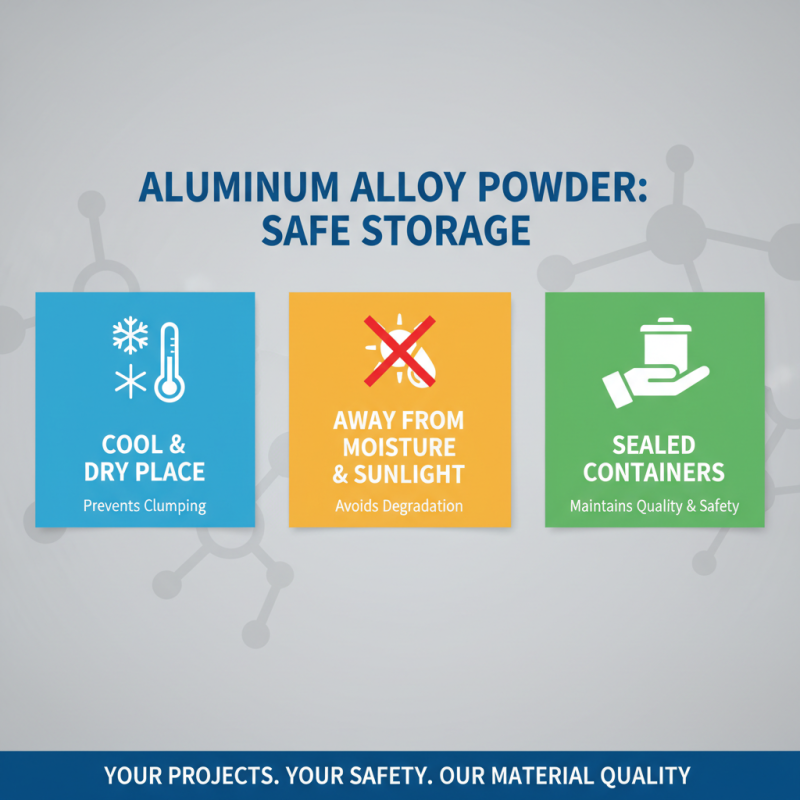

When working with aluminium alloy powder, proper storage and handling practices are crucial to ensuring safety and maintaining the quality of the material. Aluminium powder can be sensitive to environmental conditions, so it’s important to keep it in a cool, dry place away from direct sunlight and moisture. These elements can lead to clumping or degradation of the powder, making it less effective for your projects.

Tips for storing aluminium alloy powder include using air-tight containers that prevent contamination from humidity and dust. Labeling containers with the date of purchase and batch number can also help track the shelf life and quality of the material. Moreover, placing desiccants within storage containers can further assist in controlling moisture levels and preserving the powder's integrity.

When handling aluminium alloy powder, always use appropriate personal protective equipment (PPE), such as gloves and masks, to minimize inhalation risks and skin contact. Make sure the workspace is well-ventilated and free from potential ignition sources, as fine powders can be prone to combustion when dispersed in the air. Implementing these best practices will enhance safety and ensure that the aluminium alloy powder remains effective for your projects.

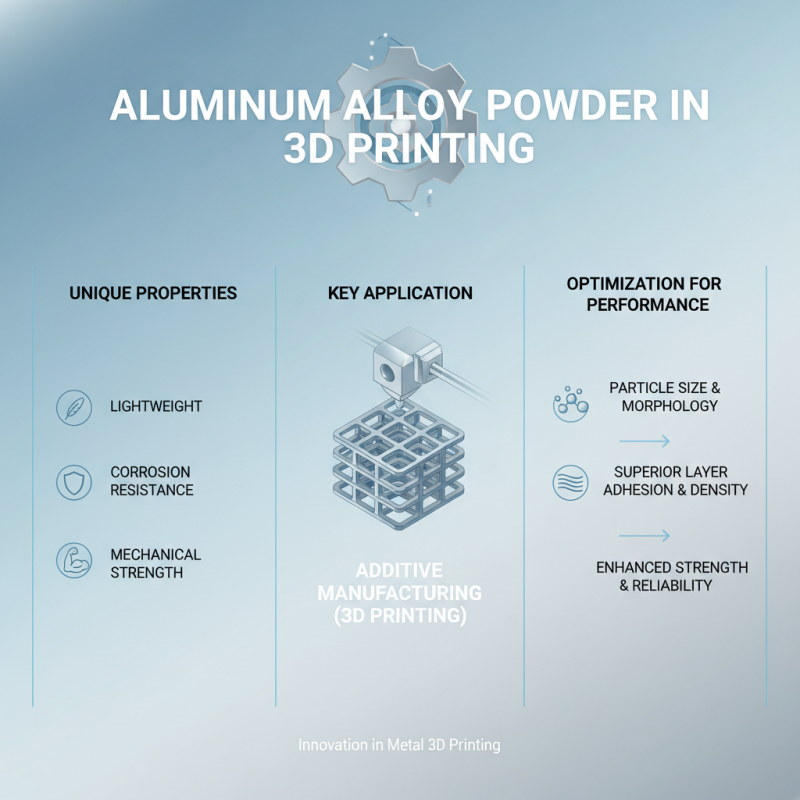

Aluminium alloy powder is increasingly being utilized in various industries for its unique properties, such as lightweight, corrosion resistance, and excellent mechanical performance. One of the most effective applications of aluminium alloy powder is in additive manufacturing, where it serves as a key material for 3D printing components. By optimizing the particle size distribution and morphology of the powder, manufacturers can achieve superior layer adhesion and density in printed parts, which translates into enhanced mechanical strength and reliability.

In addition to additive manufacturing, aluminium alloy powder is also widely used in surface coating and thermal spray applications. Techniques such as cold spraying or plasma spraying can effectively utilize this powder to create durable protective coatings on various substrates. Proper preparation techniques, including preheating the substrate and adjusting spray parameters, are essential to ensure good adhesion and performance of the applied coatings. Furthermore, compaction and sintering processes can be employed to create strong, lightweight components for automotive, aerospace, and structural applications, demonstrating the versatility of aluminium alloy powder in modern engineering solutions.