When selecting the right Aluminum Alloy Powder for your projects, several factors come into play. According to industry expert Dr. Emily Carter, “Choosing the correct powder can significantly affect the performance of your finished product.” Her insight highlights the importance of making informed decisions.

Aluminum Alloy Powder offers various benefits, including lightweight properties and resistance to corrosion. However, each alloy has its unique characteristics. It's essential to consider the intended application and required properties. Some alloys excel in strength, while others may focus on thermal or electrical conductivity.

Many users overlook the specifics of their needs. This can lead to inefficient choices and project delays. Not every Aluminum Alloy Powder fits every project's requirements. Take the time to evaluate your options thoroughly. Each decision shapes the outcome of your work.

When selecting aluminum alloy powder, understanding its various types and properties is crucial. Aluminum alloys are primarily categorized into two groups: wrought and cast alloys. Wrought alloys, which include series 1000 to 7000, are shaped and formed through mechanical processes. Cast alloys, represented by series 2000 to 8000, are melted and poured into molds. Each type has its unique attributes, affecting applications in industries such as aerospace, automotive, and construction.

Tips: Always consider strength and weight ratio. Look for data on tensile strength and elongation. Alloys like 6061 offer good mechanical properties for structural components. According to a 2022 industry report, aluminum powder usage is expected to grow by 7% annually. This growth indicates rising demand for lightweight materials in manufacturing.

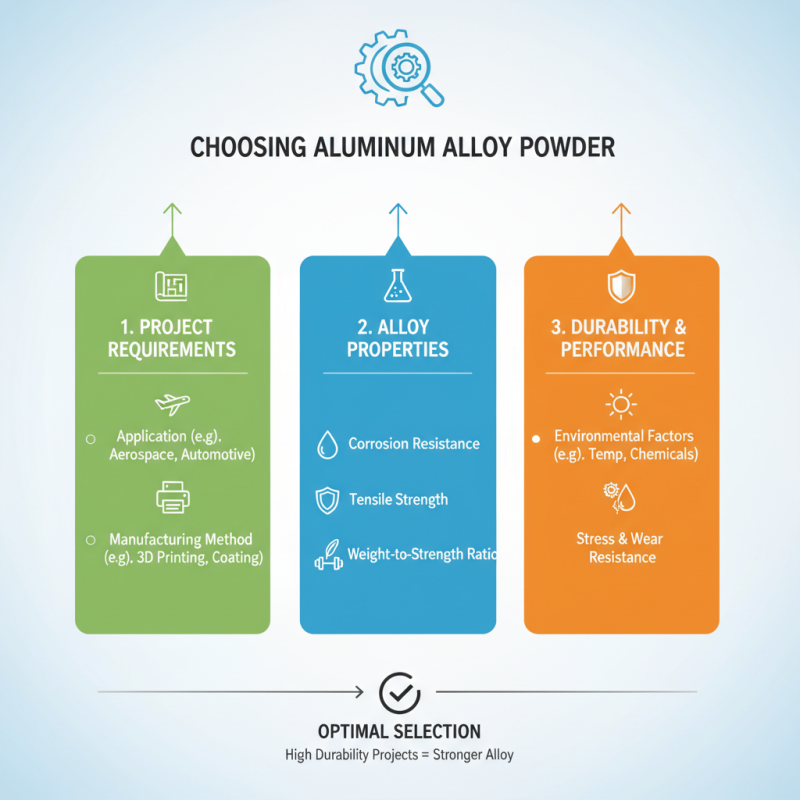

Choosing the right alloy is not straightforward. The trade-offs between corrosion resistance, thermal conductivity, and cost can be challenging. For example, while 7075-T6 is strong, it’s more expensive and harder to machine. Users must weigh these details carefully. Always revisiting your project requirements is vital to ensure that the selected alloy matches needs without overspending or compromising safety.

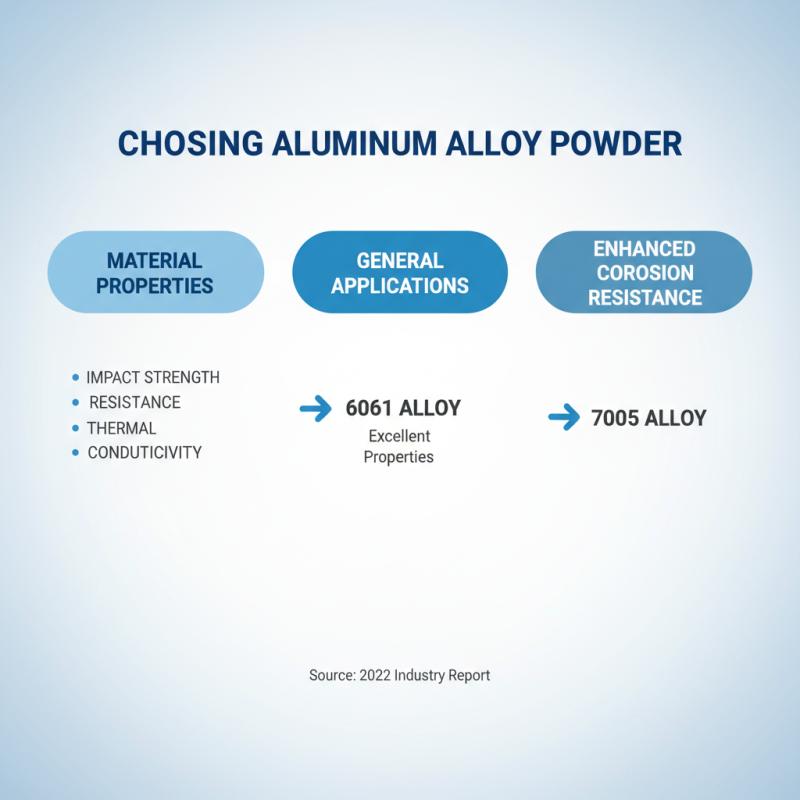

Choosing the right aluminum alloy powder involves various factors. Material properties are crucial. The specific alloy you select impacts strength, corrosion resistance, and thermal conductivity. According to a 2022 industry report, 6061 aluminum alloys are preferred for general applications due to their excellent mechanical properties. However, for applications requiring enhanced corrosion resistance, 7005 alloys may be a better choice.

Particle size is another key consideration. Smaller particles often improve flowability and packing density. Research indicates that powders with a size of 25-45 microns can provide better sintering results. Yet, finer powders may lead to increased oxidation, which could compromise their performance. The density of the powder also influences the final product quality. A 2019 study highlighted that powders with a density higher than 2.7 g/cm³ can achieve better structural integrity.

Applications vary widely. Some projects may require specific thermal or electrical conductivity. For instance, aerospace applications often prefer powders that can withstand extreme conditions. However, not all available alloys meet these rigorous demands. Buyers should analyze their specifications carefully. It's vital to recognize that selecting aluminum alloy powder is not a one-size-fits-all scenario.

When selecting aluminum alloy powders for various applications, it is essential to consider their specific uses. Aluminum alloy powders are widely utilized in additive manufacturing, automotive, aerospace, and construction industries. Each application has unique requirements that influence the choice of alloy.

For instance, aluminum alloy 6061 is commonly used in automotive parts due to its excellent corrosion resistance and machinability. According to a report by MarketsandMarkets, the global aerospace aluminum alloys market size is expected to grow from $25.4 billion in 2020 to $34.9 billion by 2025. This growth is driven by the demand for lightweight materials. However, many users may overlook the tensile strength needed for critical components.

On the other hand, alloy 2024 is favored in aerospace applications for its high strength-to-weight ratio. This alloy exhibits fatigue resistance, which is crucial for aerospace structures. Yet, its lower corrosion resistance means it is often coated. Choosing the right powder requires an understanding of these trade-offs to ensure performance meets project requirements.

| Alloy Designation | Typical Applications | Key Properties | Common Uses |

|---|---|---|---|

| 6061 | Structural components, marine applications | Good corrosion resistance, weldable, medium strength | Bicycles, automotive parts, construction materials |

| 7075 | Aerospace, military applications | High strength, low corrosion resistance | Aircraft structures, high-stress applications |

| 2024 | Aerospace, aircraft structures | High strength, poor corrosion resistance | Aircraft skins, ribs, stringers |

| 5083 | Marine industry, pressure vessels | Excellent corrosion resistance, good weldability | Boat hulls, pressure vessels |

| 3003 | Common applications in industry | Good corrosion resistance, moderate strength | Cooking utensils, chemical equipment |

When selecting aluminum alloy powders for your projects, understanding the processing techniques is essential. Different methods can significantly affect the final product's properties. There are several common techniques for processing aluminum powders. These include mechanical milling, atomization, and gas condensation. Each method has its own advantages and challenges.

**Tip:** Always consider particle size. Smaller particles enhance reactivity but can complicate processing.

Mechanical milling is a widely used method. It involves grinding aluminum alloy chunks into fine powders. This method can produce highly uniform particles. However, it may also introduce impurities. It's important to monitor the process carefully to maintain quality and performance.

**Tip:** Keep an eye on temperature changes during milling. Excessive heat can alter the powder's properties.

Atomization involves spraying molten aluminum alloys into a gas or liquid medium. This process creates spherical particles that are ideal for many applications. While effective, controlling the cooling rate can be tricky. A rapid cooling process prevents oxidation but requires precise equipment.

Understanding the processing techniques allows for better selection of the right aluminum alloy powder for your project. It's a balancing act between desired properties and manufacturing capabilities.

Choosing the right aluminum alloy powder involves careful consideration of several factors. First, understand the specific requirements of your project. Different alloys have unique properties. Some may offer better corrosion resistance, while others have superior strength. For instance, if your project requires high durability, a stronger alloy will be essential.

When selecting an alloy, pay attention to the particle size. Smaller particles can enhance surface area and improve reactivity. However, fine powders may also pose handling challenges. It’s crucial to find a balance between performance and practicality. Also, consider the manufacturing method. Some alloys perform better with specific techniques, such as additive manufacturing or traditional casting.

Testing is often overlooked but is vital. Run trials to assess how the chosen powder behaves in real-world conditions. Sometimes, an alloy may look perfect on paper but fails during application. These moments can offer insightful lessons. Reflecting on these experiences can guide future selections, ensuring more successful projects down the line.