As we look ahead to 2026, the landscape of 3D printing materials is rapidly evolving. These materials are not just functional; they offer creative opportunities for various projects. From prototyping to artistic designs, understanding the best materials is essential for success.

In this dynamic field, factors like strength, flexibility, and ease of use come into play. New advancements in technology are introducing unique options every year. It's crucial to experiment with different materials to find the right fit. Yet, selecting the best 3D printing materials can be challenging. The options can be overwhelming, leading to confusion and misjudgments.

Mistakes happen, and sometimes a material may not perform as expected. This reality prompts us to reflect on our choices. Embracing the journey of trial and error is part of the creative process. As we explore the top materials for 2026, let's keep an open mind and thrive on innovation. This approach can elevate our projects and expand our understanding of 3D printing.

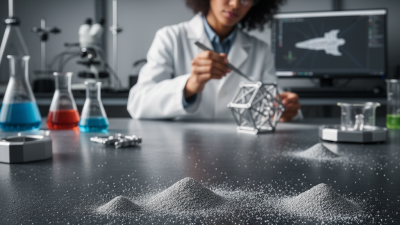

In 2026, the landscape of 3D printing materials is vast and varied. Consumers and businesses alike have more options than ever. Common materials such as PLA and ABS remain favorites. They are user-friendly and versatile. However, new materials are gaining traction. For instance, metal-infused filaments are becoming popular for functional parts. These materials offer durability and strength, ideal for specific applications.

When choosing materials, consider the project’s requirements. Some projects may need flexibility, while others require rigidity. Experimenting is key. This exploration will reveal potential issues. For example, not all materials adhere well to each other. Test prints can help uncover these flaws before committing to a full print.

Tips: Always check compatibility with your printer. Some materials may require specific settings. Additionally, consider environmental factors like humidity. Moisture can alter the quality of prints. A well-prepared work environment improves results significantly. Balancing these elements will enhance your 3D printing experience.

| Material Type | Best For | Strength | Flexibility | Heat Resistance | Cost per kg |

|---|---|---|---|---|---|

| PLA | General Prototyping | Medium | Low | Low | $20 |

| ABS | Durable Parts | High | Medium | Medium | $25 |

| PETG | Food Containers | Medium | High | Medium | $30 |

| TPU | Flexible Parts | Medium | Very High | Low | $35 |

| Nylon | Industrial Parts | High | Medium | High | $40 |

Choosing the right materials for 3D printing is crucial for project success. Several factors should guide your decision. One key aspect is the material's strength. For functional parts, opt for stronger materials that can withstand stress. If your project is aesthetic, lighter materials might suffice.

Another essential factor is printability. Some materials are more challenging to work with due to their tendency to warp or require specific settings. Testing various materials can lead to unexpected challenges. Additionally, consider the temperature resistance of the material. Exposure to heat can deform some plastics.

Cost is a practical consideration. High-quality materials often come at a premium price. Balancing your budget with performance needs can be tricky. It's beneficial to experiment with lower-cost options before committing to expensive ones. Lastly, think about the finish quality. Some materials yield smoother finishes, while others may require post-processing. Reflection on these factors will significantly impact your 3D printing outcomes.

When it comes to prototyping and design projects, selecting the right 3D printing material is crucial. Different projects require different properties. For instance, PLA is user-friendly and eco-friendly, making it popular among beginners. Its ease of printing helps in creating basic prototypes quickly. However, this material may not withstand high temperatures.

On the other hand, ABS offers strength and durability. It is suitable for functional prototypes. Yet, printing with ABS can be tricky. The material tends to warp during cooling, which can lead to failed prints. Challenges like these require trial and error, pushing designers to refine their approaches.

Another option is PETG, which combines strength with flexibility. This material is resistant to moisture and high impact, ideal for more demanding designs. Still, it can be stringy during the printing process, requiring careful adjustments. Designers must frequently experiment and adjust settings. Each material choice comes with its own set of challenges. The journey to find the perfect fit can be rewarding but also frustrating.

In 2026, the landscape of 3D printing materials for functional and mechanical applications has broadened significantly. The rise of advanced composites has transformed traditional manufacturing processes. A report from Smith & Associates points to a 40% growth in composite material usage for mechanical parts. This trend underlines the industry's shift towards durability and performance.

Polymers are gaining ground too, especially in engineering applications. According to recent data, engineering-grade thermoplastics accounted for over 30% of material consumption in 2026. These polymers offer unique features like resistance to heat and chemicals. However, many still struggle with printing complexity and layer adhesion, leading to potential failures.

Despite these advancements, challenges remain. Not every material meets specific project requirements. For example, some composites are still hard to process, leading to inconsistencies. A recent survey indicated that 25% of companies report difficulty in material selection. This highlights the ongoing need for better education and resources in the industry. Understanding material properties is becoming crucial for success. This evolution is both exciting and daunting for practitioners in the field.

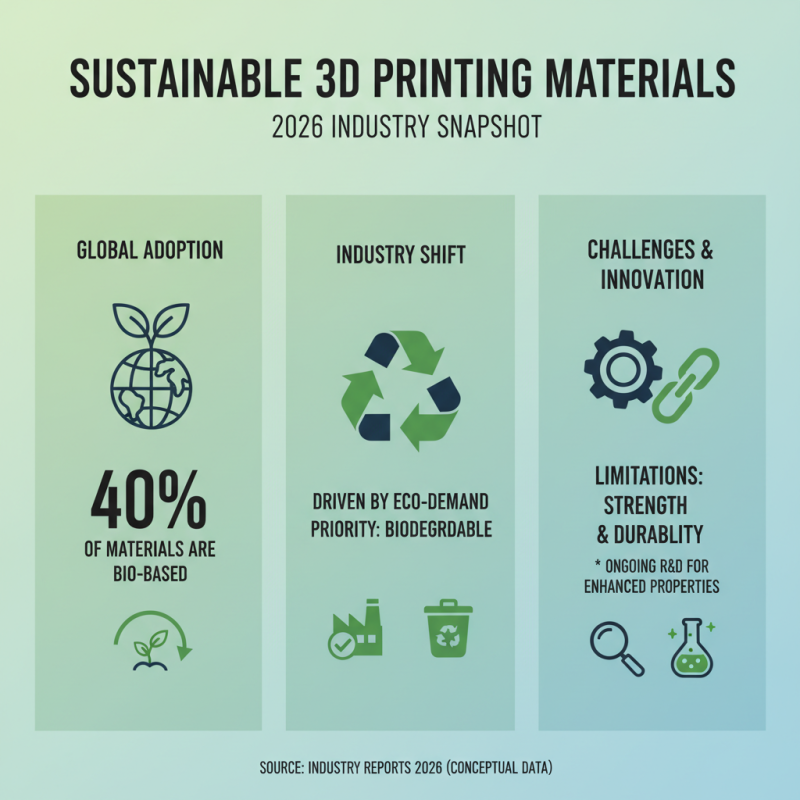

In 2026, sustainable 3D printing materials are gaining significant traction in the industry. Reports indicate that around 40% of 3D printing materials used are now bio-based. This shift reflects the growing demand for environmentally friendly alternatives. Many projects are prioritizing biodegradable materials. However, these materials often come with limitations in strength and durability.

Innovations in recycling processes are emerging. For instance, filament made from recycled plastics is becoming more common. It reduces waste and lowers production costs. Yet, the performance of recycled materials still clashes with their virgin counterparts. Some users notice weaker layers in prints. This inconsistency raises questions about their reliability for critical applications.

While progress is evident, challenges remain. The transition to sustainable materials isn't seamless. Many projects struggle to find the right balance between quality and eco-friendliness. Industry reports highlight a need for more research. Only through ongoing exploration can the full potential of sustainable 3D printing be realized. The future depends on overcoming these hurdles with creative solutions.