Aluminum Black Powder has become a staple in various industries. Its unique properties make it indispensable in manufacturing and energy sectors. Dr. Emily Carter, an expert in materials science, emphasizes, "Aluminum Black Powder transforms innovation in energy solutions." This highlights its critical role in modern technology.

In aerospace, Aluminum Black Powder is crucial for fuel formulations. Its energy density is impressive, enabling better performance. However, challenges in safety protocols remain. Ensuring safe handling is a priority. For manufacturers, the production process of Aluminum Black Powder must maintain quality and consistency.

Yet, despite these advancements, oversight is necessary. The industry must address environmental impacts. Proper disposal and recycling methods are vital. As industries evolve, the demand for Aluminum Black Powder will continue to grow. Balancing innovation with responsibility is essential for future developments.

Aluminum black powder is known for its versatile applications across various industries. Its chemical composition primarily consists of aluminum particles, often combined with other materials to enhance its properties. The average particle size typically ranges from 15 to 30 micrometers, influencing its reactivity and efficiency. Reports indicate that this specific size facilitates faster combustion, making it essential in the pyrotechnics and aerospace sectors.

The properties of aluminum black powder contribute to its widespread use. The material exhibits a low density, which can lead to weight savings in applications like propellants and explosives. However, achieving the desired level of stability can be challenging. Variations in the production process can yield inconsistent results, leading to potential safety concerns. It's noted that up to 90% of batch inconsistencies arise from contamination or incorrect handling, underscoring the importance of stringent quality control.

In applications such as metallurgy, aluminum black powder serves as a reducing agent. It aids in the production of alloys and facilitates the sintering process. However, the burning rate can vary significantly depending on the formulation. This variability calls for careful testing and adjustment. Users must regularly evaluate the performance to ensure it meets specific industry standards. Making assumptions without thorough testing can lead to costly mistakes.

Aluminum black powder is pivotal in the defense industry. This substance is primarily known for its use in propellants and explosives. Notably, its unique properties enhance performance and stability. Reports indicate that aluminum black powder increases the energy output of explosive materials. This effect is crucial in both military and aerospace applications.

In military operations, precision is vital. The increased energy from aluminum black powder allows for better projectile velocity. It improves the effectiveness of munitions. According to industry analyses, munitions containing aluminum black powder demonstrated a 20% increase in blast efficiency. Additionally, its lightweight nature contributes to easier transportation and deployment in various scenarios.

However, the handling of aluminum black powder requires caution. While it offers significant advantages, safety protocols are essential. There are risks associated with dust formation during processing. Production facilities must adhere to strict safety guidelines. Training personnel on these procedures is paramount. Continuous improvement in safety practices is necessary to mitigate potential hazards in the manufacturing process.

| Application Area | Description | Benefits |

|---|---|---|

| Explosives | Used as a fuel component in composite explosives to improve performance. | Increased energy output and efficiency in explosive reactions. |

| Propellants | Acts as an oxidizer in solid rocket propellants to enhance thrust. | Improved thrust-to-weight ratio for missile and space applications. |

| Pyrotechnics | Used in flares, fireworks, and other signaling devices. | High visibility and reliability in signaling and illumination applications. |

| Coatings | Applied as a protective layer in military equipment to reduce wear and corrosion. | Extended lifespan and durability of defense equipment. |

| Battery Technology | Involved in the production of lighter, efficient batteries for tactical use. | Enhanced energy density and reduced overall weight of power sources. |

Aluminum black powder plays a crucial role in aerospace engineering. Its unique properties make it a preferred choice for many applications. This powder is lightweight yet strong, allowing engineers to create components that reduce overall aircraft weight. The use of aluminum black powder can enhance fuel efficiency, a significant factor in modern aviation.

In the aerospace sector, this material is often used in propulsion systems. It serves as a component in solid rocket propellants. However, operational challenges exist. The handling and storage of this powder require strict protocols. Improper procedures can lead to safety issues. Engineers must constantly assess these risks.

Moreover, aluminum black powder contributes to advanced coating processes. These coatings protect metal surfaces from corrosion. The durability offered by these coatings is invaluable. But, there are questions about their long-term effectiveness. Continuous research is necessary to ensure reliability. Engineers often must balance innovation with safety.

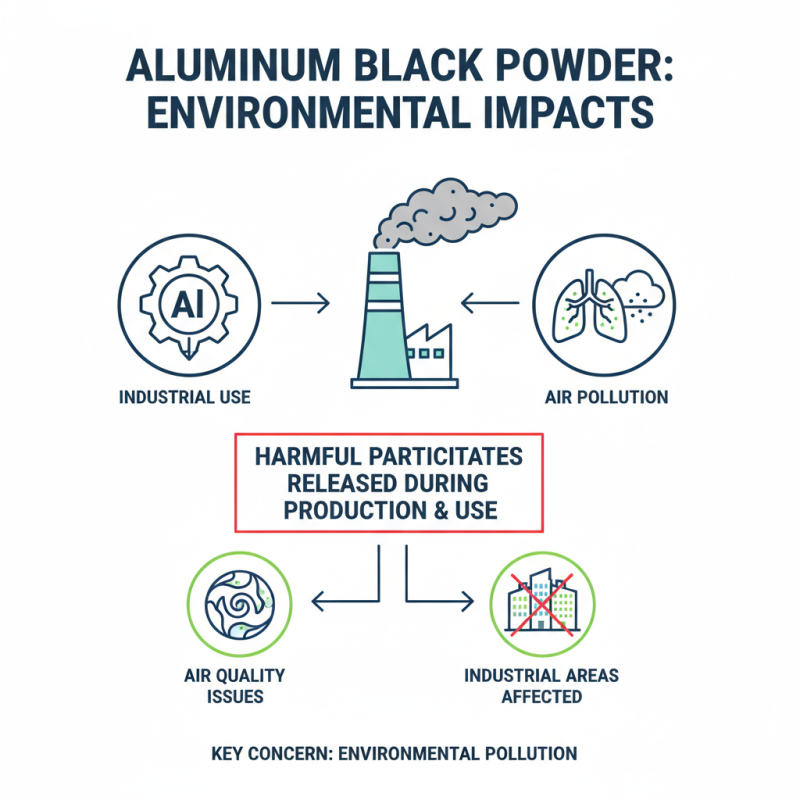

The use of aluminum black powder in industries raises important environmental questions. This material, while effective in various applications, often generates pollution. When aluminum black powder is produced and used, it can release harmful particles into the air. These emissions contribute to air quality issues, particularly in industrial areas.

Moreover, the disposal of aluminum black powder presents challenges. Improper disposal can lead to soil contamination. Heavy metals may leach into groundwater, affecting local ecosystems. Companies need to evaluate their waste management practices carefully.

Recycling aluminum black powder is one solution but is not widely adopted. There is a need for innovation in safe disposal and recycling methods. The industry should explore sustainable alternatives or improvements. Balancing efficiency and environmental responsibility is crucial. Reflecting on these aspects can guide future developments for a sustainable future.

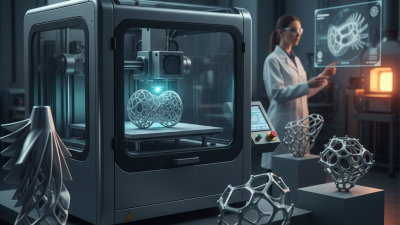

Aluminum black powder has gained significant attention across various industries. This interest stems from its unique properties and versatility. Recent market research suggests a projected growth rate of over 5% annually for aluminum black powder in the manufacturing sector. Various applications can be enhanced through innovations in this area.

Future trends indicate a shift towards eco-friendly formulations. Industries are vying to minimize their carbon footprint. As a result, more companies are focusing on sustainable alternatives to traditional materials. Researchers are exploring novel methods to produce aluminum black powder while reducing waste. This shift may present new opportunities and challenges in formulation stability.

Tips: Always consider the environmental impact of materials used in production. Invest in research to find greener alternatives. Regularly reassess supply chains to enhance sustainability.

Experimentation with aluminum black powder can yield varying results. It might require further understanding of reaction dynamics. Identifying compatible materials is crucial for optimized performance. Collaboration between industries and academic institutions could drive this innovation forward. The focus on adaptability and safety will be vital in future developments.