Aluminium Alloy Powder is a versatile material widely used in various industries. Expert Dr. Jane Smith, a renowned materials scientist, states, “The potential of Aluminium Alloy Powder is remarkable, especially in modern engineering applications.” This powder is not just lightweight; it offers impressive strength and durability.

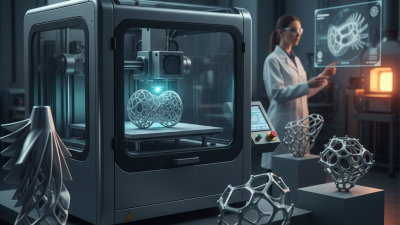

In aerospace, automotive, and additive manufacturing, Aluminium Alloy Powder enhances performance. It aids in producing complex shapes quickly. These benefits streamline production processes, saving both time and resources. Users have reported increased efficiency in their projects. However, challenges remain in ensuring uniformity and proper handling.

Some manufacturers struggle with quality control. Inconsistent particle size and distribution can affect the final product. Industry leaders must continue to innovate. They must refine the production techniques to fully harness the benefits of Aluminium Alloy Powder. The future of this material shows promise, but there is still room for improvement and adaptation.

Aluminium alloy powder has gained attention for its diverse applications and benefits. This fine material is created from various aluminium alloys through a controlled atomization process. The resulting powder features excellent mechanical properties and is lightweight. It is extensively used in 3D printing, automotive, and aerospace industries.

One of the key benefits of aluminium alloy powder is its ability to promote efficient production. The powder can be easily manipulated to create complex shapes that are difficult to achieve with traditional methods. This capability can lead to reduced waste and lower manufacturing costs. However, achieving consistency in powder quality can be challenging. Variability in particle size and shape may affect the final product.

Tips: Consider using aluminium alloy powder for projects requiring strength and lightness. Testing different alloys can yield surprising outcomes. Always ensure proper handling to maximize safety and effectiveness.

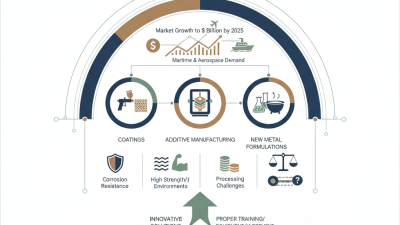

This chart illustrates the various applications of aluminium alloy powder across different industries and their respective utilization ratios. As shown, the automotive and aerospace industries are the leading consumers of aluminium alloy powder, demonstrating its significance in these sectors.

Aluminium alloy powder has numerous applications across various industries. It is commonly used in additive manufacturing, particularly in 3D printing. This technology allows for the creation of complex geometries. The lightweight nature of aluminium alloy powder contributes positively to the performance of the final products. It also offers excellent mechanical properties, making it suitable for high-stress environments.

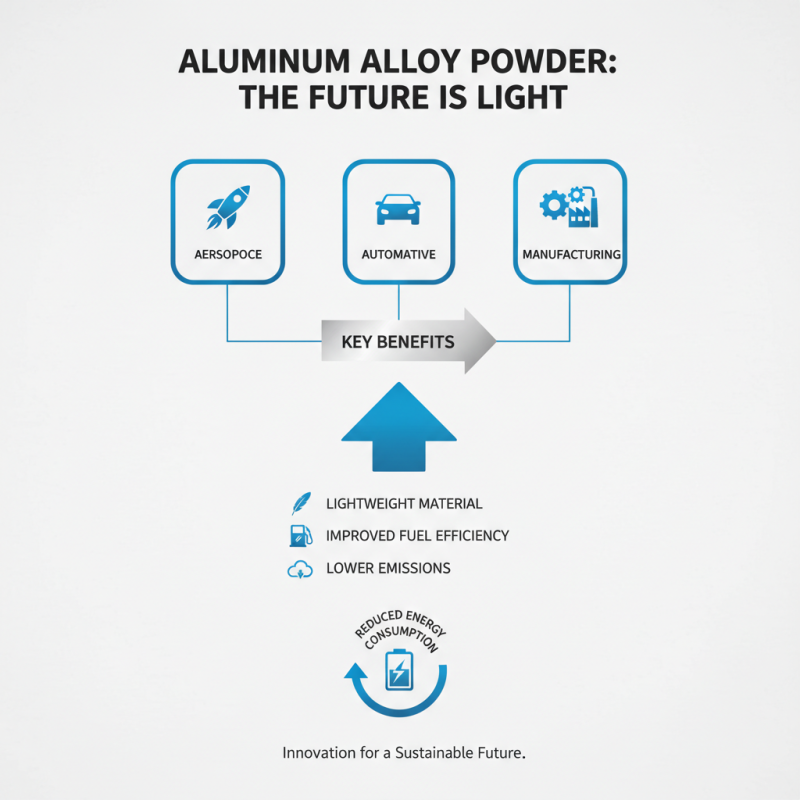

Additionally, aluminium alloy powder finds use in the automotive sector. It helps reduce vehicle weight, thereby improving fuel efficiency. In the aerospace industry, it is essential for producing aircraft components that require both strength and lightweight characteristics. These applications often push the limits of design, resulting in innovative solutions. However, this process can be tricky, as some are still figuring out the optimal powder characteristics.

In the field of coatings, aluminium alloy powder provides corrosion resistance. It improves the durability of surfaces exposed to harsh environments. While the benefits are significant, not every formulation may yield desired results. It’s important for manufacturers to conduct thorough testing. Overall, the versatile nature of aluminium alloy powder continues to open new doors for innovation.

Aluminium alloy powder has gained popularity across various industries due to its unique properties. This material is lightweight, which means it can reduce energy consumption in transportation. Industries such as aerospace and automotive benefit significantly from this advantage. Using aluminium alloy powder can lead to improved fuel efficiency and lower emissions.

In the construction sector, aluminium alloy powder helps create durable and corrosion-resistant materials. It provides structural integrity and longevity. However, achieving the right balance between strength and weight can be challenging. Some applications may require careful engineering to avoid potential weaknesses.

However, not all uses of aluminium alloy powder are straightforward. Some processes involve complex production steps, which can lead to inconsistencies. These imperfections can impact performance. Industries must invest time in research and development to fully harness its benefits. Ultimately, while the advantages are clear, the journey toward optimization can be complex and demanding.

Aluminium alloy powder serves various industries, offering unique advantages over other metal powders. When compared to steel powders, aluminium powders are lighter yet strong. According to industry reports, aluminium alloys weigh 70% less than steel products, providing significant weight savings in applications like aerospace and automotive sectors.

Tips: Consider weight reduction in your designs. It can enhance efficiency and reduce costs.

Aluminium alloy powder also has excellent corrosion resistance. This property makes it preferable for outdoor applications. While steel powders can rust, aluminium's oxide layer prevents degradation. Some may question the cost-effectiveness. Market analysis shows that although aluminium powders can be pricier, their longevity often offsets initial expenses.

Tips: Always evaluate the total cost of ownership. Sometimes, higher initial costs lead to lower maintenance in the long run.

In a comparison with titanium powders, aluminium is less brittle. However, titanium offers superior strength. Manufacturers often weigh these factors based on specific project needs. Choosing the right powder demands careful consideration of both material properties and their resulting performance. Keep in mind that not every application benefits equally from aluminium alloy powder.

The future of aluminium alloy powder technology looks bright. Researchers are developing innovative ways to enhance its properties. This includes improving the mechanical strength and thermal conductivity of powders. As industries demand better materials, aluminium alloy powders are becoming essential.

Adoption of advanced manufacturing techniques is a significant trend. Techniques like additive manufacturing are gaining traction. They allow for complex geometries that traditional methods cannot achieve. This flexibility can lead to more efficient designs. However, the learning curve can be steep. Companies must invest time to adapt to these changes.

Tips: Focus on quality over quantity when sourcing materials. Ensure you understand the composition of the powders. A clear understanding can prevent issues later. Also, consider how the end-use of the product might impact your choice of alloy. This can save time and resources. As the sector evolves, staying informed is crucial.

| Application | Benefits | Future Trends |

|---|---|---|

| Additive Manufacturing (3D Printing) | Lightweight structures, complex geometries | Enhanced printing techniques, higher material efficiency |

| Powder Coating | Durable and corrosion-resistant finishes | Eco-friendly formulations, automated application processes |

| Aerospace Components | High strength-to-weight ratio, superior fatigue resistance | Advanced alloy development, improved manufacturing processes |

| Automotive Applications | Increased fuel efficiency, reduced emissions | Smart materials, integrated manufacturing solutions |