The landscape of Sintered Aluminium Powder is evolving rapidly. Experts forecast a significant shift towards advanced manufacturing processes and sustainable practices. According to a recent report by TechIndustry, the market for sintered aluminium is expected to grow by over 25% by 2026. This growth is driven by innovations in material properties and applications across various sectors, including automotive and aerospace.

Dr. Emily Carter, a leading expert in the field, emphasizes, "The future of Sintered Aluminium Powder lies in its ability to meet the demands for lightweight, high-strength materials." Companies are now focusing on finer particle sizes and enhanced sintering techniques to improve product performance. However, challenges remain. The industry must address the environmental impact of production processes and the need for recyclability.

As the market expands, stakeholders face pressure to innovate. Organizations are tasked with balancing efficiency and ecological responsibility. This juxtaposition offers opportunities for groundbreaking advancements in Sintered Aluminium Powder while prompting critical reflection on long-term sustainability practices.

Sintered aluminium powder technologies have evolved rapidly. The current state reflects a versatile approach to manufacturing. Industries now leverage advanced techniques to create complex geometries. These innovations in powder metallurgy enhance performance in various applications.

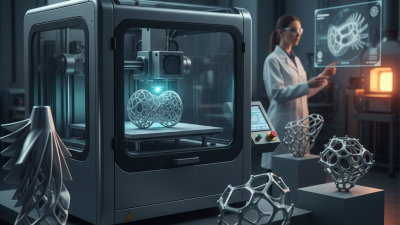

One notable trend is the integration of additive manufacturing. This method enables the production of lightweight components. Such components are crucial in automotive and aerospace sectors. However, challenges remain in achieving uniform density across parts. Also, the cost of materials can be high, limiting widespread adoption.

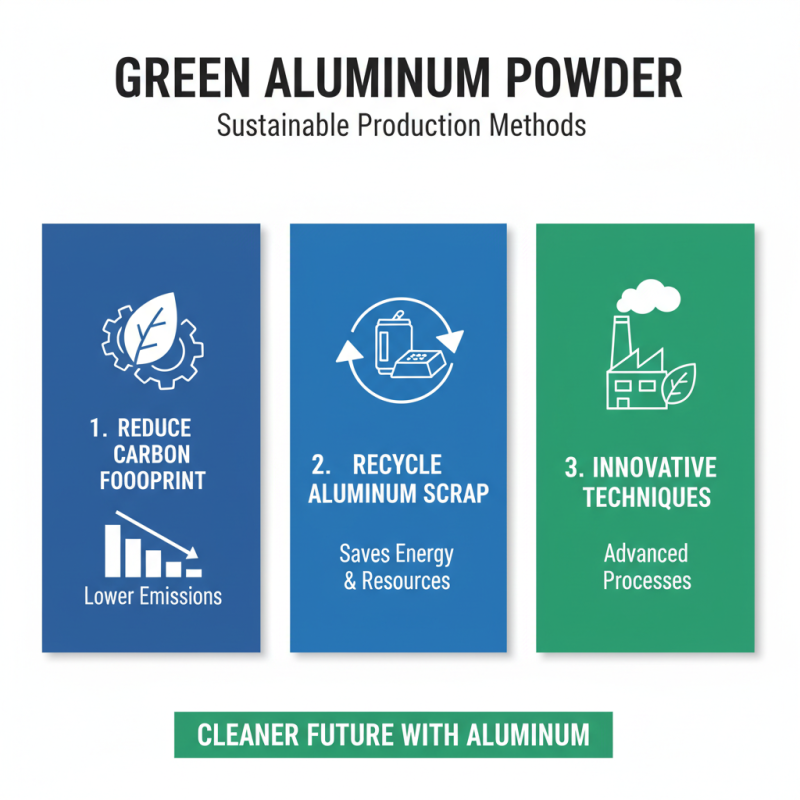

Sustainability is becoming a key focus. Companies explore ways to recycle and reuse aluminium powder efficiently. This shift could reduce environmental impact in the long term. Yet, optimizing these processes requires further research and investment. Overall, the current state of sintered aluminium powder technologies shows promise but needs continuous improvement.

The advancements in sintered aluminium powder technology in 2026 are remarkable. By leveraging innovative processing techniques, manufacturers are optimizing the density and flowability of powders. Recent studies show that the use of advanced sintering methods can increase yield by up to 25%. This is a significant leap compared to traditional methods, which often have limitations in achieving uniform particle distribution.

In addition, the incorporation of artificial intelligence is reshaping production processes. AI-driven systems can predict material behavior, reducing trial and error. This transformation can decrease production time by around 20%. However, reliance on such technology poses risks. For instance, depending solely on automated systems might overlook certain nuances of material properties that require human expertise.

Sustainability plays a crucial role too. A report from an industry leader reveals that eco-friendly approaches reduce carbon footprints by 30%. Still, the transition to greener practices can be slow. Suppliers may face challenges in sourcing sustainable materials. The balance between innovation and practicality remains delicate, urging industry players to constantly rethink their strategies.

| Trend | Description | Impact Level | Adoption Rate (%) |

|---|---|---|---|

| Eco-friendly Powders | Development of sintered aluminium powders using recycled materials to reduce ecological footprint. | High | 75 |

| 3D Printing Applications | Enhancements in sintered aluminium powders optimize them for 3D printing processes, enabling complex geometries. | Medium | 60 |

| High-Performance Alloys | Introduction of new alloy compositions that enhance strength and performance in demanding applications. | Very High | 80 |

| Nanostructured Powders | Development of nanostructured aluminium powders that provide superior mechanical properties and thermal resistance. | High | 65 |

| Customization Capabilities | Offerings of bespoke powder formulations tailored to specific industrial needs and requirements. | Medium | 55 |

Sustainability is becoming a critical focus in aluminium powder production. As companies seek ways to minimize their carbon footprint, innovative techniques are emerging. Recycling scrap aluminium is one effective method. This process not only reduces waste but also conserves energy.

Adopting advanced sintering technologies can further enhance sustainability. These approaches often use less energy and produce fewer emissions. For example, using renewable energy sources can transform the production landscape. Many companies are exploring this path.

Tips: Implementing small changes can lead to significant impacts. Use local sources for raw materials. This reduces transportation emissions. Regular maintenance of equipment can also improve efficiency.

Innovation in sintering methods plays a crucial role too. Techniques like selective laser sintering are gaining traction. They offer better material properties and lower waste. However, challenges remain. Not all innovations are scalable or feasible yet. Balancing performance and sustainability continues to be a complex task.

Sintered aluminium powder has emerged as a significant material in various industries due to its unique properties. The aerospace sector particularly benefits from its lightweight nature and strength. Components manufactured from sintered aluminium can endure high-stress environments. These parts also ensure fuel efficiency and lower emissions.

The automotive industry is rapidly adopting this technology. Manufacturers are using sintered aluminium for engine components and structural parts. This shift aids in producing lighter vehicles. It also contributes to improved performance and reduced fuel consumption. However, some may worry about production methods. Ensuring quality and uniformity can be challenging.

Tips: Always consider material source. Understanding the process helps in achieving desired performance. Testing is crucial too. Rigorous quality checks can save time and resources.

In the electronics sector, sintered aluminium is gaining traction. Its excellent thermal conductivity makes it ideal for heat sinks. This aids in cooling electronic devices effectively. Yet, there can be issues with oxidation. A protective coating may be necessary. Exploring innovative solutions can lead to better longevity and reliability.

The chart above illustrates the projected market growth for sintered aluminium powder across various industries in 2026. The automotive sector leads with an estimated growth of 1500 million USD, followed by aerospace and consumer electronics, showcasing the increasing applications and innovations in this material.

The future of sintered aluminium powder innovations holds great promise, yet it also presents numerous challenges. According to industry reports, the global market for aluminium powder is expected to reach $3.5 billion by 2026. This growth is driven by increased demand in aerospace, automotive, and consumer goods sectors. However, the production process often faces hurdles. The consistency of particle size and shape can significantly affect the final product's quality.

Tips: Ensure proper testing of materials. This helps maintain quality and performance.

Sintering techniques have improved with advances in technology, but cost remains a concern. Implementing new methods may require substantial investment. Companies must weigh the cost versus potential benefits. Furthermore, sustainability remains a hot topic. The need for environmentally friendly production methods is growing. A shift to recycled aluminium powder could ease environmental impacts.

Tips: Explore partnerships with sustainable suppliers. This can enhance brand reputation and reduce carbon footprints.

The path forward for sintered aluminium powder innovations is complex. The industry must adapt to changing demands and technological shifts. Addressing these challenges effectively will define the future landscape of this evolving field.