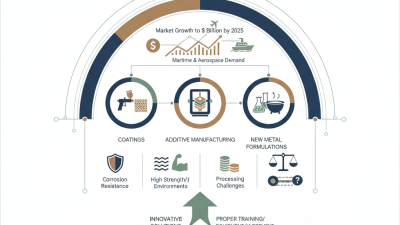

Aluminum Black Powder has gained significant traction in various industries, leading to notable advancements. According to a recent report by MarketsandMarkets, the global aluminum powder market is projected to reach $10.3 billion by 2027, with Aluminum Black Powder being a key component driving this growth. Its unique properties, including high energy density and lightweight nature, make it indispensable in sectors like aerospace and automotive.

Furthermore, the use of Aluminum Black Powder in pyrotechnics and fireworks demonstrates its versatility. The material not only improves combustion efficiency but also enhances color vibrancy. However, this widespread use raises questions about safety practices and storage standards, as mishandling can lead to unintended consequences. While its applications are promising, industry professionals must remain vigilant.

Understanding the top uses of Aluminum Black Powder is essential for maximizing benefits while minimizing risks. This engaging material offers vast potential, yet it demands respect and careful consideration. Identifying proper usage can ensure that this powerful substance is employed effectively across its varied applications.

Aluminum black powder is a unique material with various applications. It consists of aluminum particles that have been coated with a black oxide layer. This gives it distinct properties that enhance its performance in different uses. Understanding how it works is crucial for anyone interested in chemistry or materials science.

In pyrotechnics, aluminum black powder serves as an important component. It helps create vibrant effects and enhances the brightness of fireworks. The powder burns at a rapid rate, producing a significant amount of energy. However, handling it requires caution. Even small amounts can ignite unexpectedly if not stored properly.

Beyond entertainment, aluminum black powder finds its place in metalworking and welding. It acts as a reducing agent, aiding in processes like aluminum extraction. Yet, its misuse can lead to serious risks. Educating oneself about safety practices is essential when working with this material. It's vital to respect the potential hazards and ensure a safe environment.

Aluminum black powder is gaining attention for its unique properties and various applications. It is primarily composed of finely powdered aluminum, which gives it distinctive characteristics. The fine particle size enhances its reactivity, making it suitable for energetic formulations. This reactivity can be crucial when considering safety measures and handling procedures.

One notable feature is its lightweight nature. This makes aluminum black powder highly desirable in industries where weight is a critical factor. It also possesses excellent energy density. This property allows it to be an efficient component in certain composite materials. However, working with aluminum black powder requires careful consideration of storage and containment practices. Its fine particles can pose inhalation risks, and this is an important point to reflect on for users.

Besides its practical uses, aluminum black powder has a visually striking dark finish. This can be leveraged in artistic applications or coatings. The versatility of aluminum black powder is undeniable, yet it demands respect due to its reactive potential. Understanding its properties can lead to innovative uses, but awareness of the associated risks is essential for safety.

| Use Case | Key Properties | Characteristics | Applications |

|---|---|---|---|

| Pyrotechnics | High reactivity | Produces bright flashes | Fireworks, flares |

| Metallurgy | Lightweight | Enhances metal properties | Production of alloys |

| Energy Generation | High energy density | Efficient combustion | Fuel for power plants |

| Aerospace | Corrosion-resistant | High strength-to-weight ratio | Aircraft and spacecraft components |

| Construction | Durable | Shock absorbent | Building materials |

Aluminum black powder is gaining traction in various industries. In 2026, its applications are expected to expand significantly. According to industry reports, the global market for aluminum black powder is projected to grow by 4.5% annually. This increase is fueled by the material’s unique properties, such as lightweight and high reactivity.

In the aerospace sector, aluminum black powder is used in propulsion systems. Its high energy content makes it suitable for improving fuel efficiency. The automotive industry also taps into its potential. Lightweight components lead to better performance and reduced emissions. Furthermore, it plays a crucial role in pyrotechnics and fireworks. The vibrant colors generated from aluminum black powder provide captivating displays.

Tips: When working with aluminum black powder, handle it carefully. It is essential to store it in a cool, dry place. Moreover, ensure proper ventilation during applications to avoid any risks. Reflecting on safety practices is vital. Overlooking these aspects can lead to serious incidents. Regular training for workers in handling materials is necessary to promote a safer work environment.

Aluminum black powder is widely used for various applications, including pyrotechnics and metalworking. However, safety remains a critical concern. According to the National Fire Protection Association (NFPA), fine powders can pose serious risks, including fire and explosion hazards.

When handling aluminum black powder, PPE (personal protective equipment) is essential. Use gloves, goggles, and dust masks to minimize exposure. A well-ventilated workspace reduces the accumulation of dust. Dust can ignite easily, so it’s important to keep areas clean and free of excess powder.

Tips: Always store aluminum black powder in a cool, dry place. Avoid mixing it with other materials unless you are trained and informed about the risks. Regularly check for any signs of degradation. Staying informed about handling protocols will enhance safety and prevent accidents.

Despite precautions, mishaps can happen. Sometimes, the environment may be unpredictable. For instance, one minor spark can lead to huge consequences. Review your safety measures regularly and adjust as needed. Safety should never be an afterthought; it must be a priority.

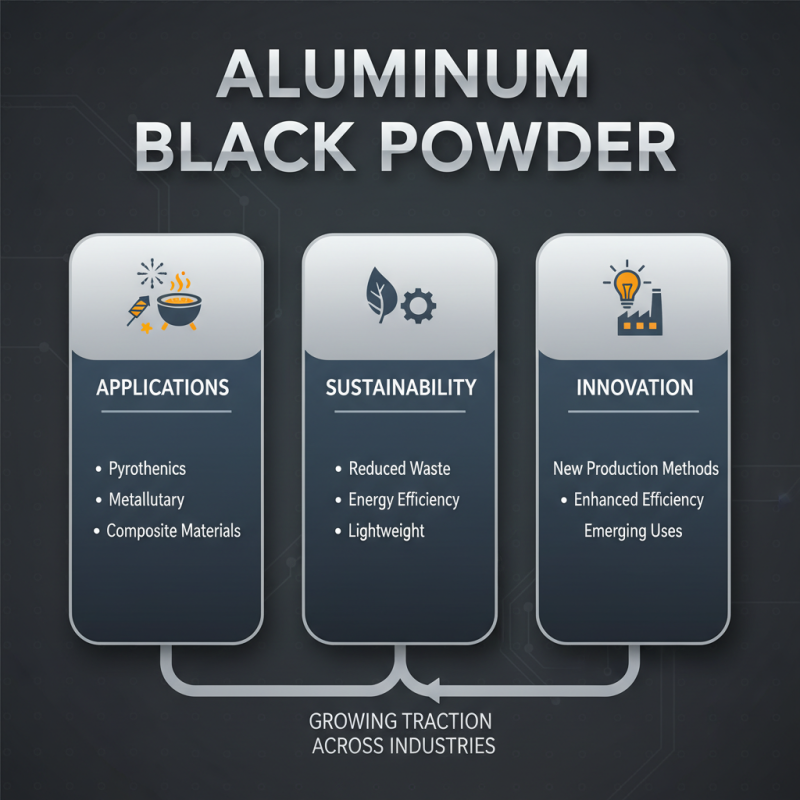

Aluminum black powder is gaining traction in various fields. Its applications extend from pyrotechnics to metallurgy. As industries shift towards more sustainable practices, this material is becoming increasingly relevant. Its lightweight nature makes it ideal for composite materials. Innovations are emerging in its production methods, enhancing efficiency and reducing waste.

Recent developments include the use of aluminum black powder in energy applications. Researchers are exploring its potential in batteries. This could lead to lighter, more efficient energy storage solutions. Engineers are experimenting with incorporating it into 3D printing. This approach aims to create robust prototypes quickly.

Yet, challenges remain. The consistency of aluminum black powder can vary. This inconsistency affects its performance in critical applications. Future research must address these variations. Additionally, safety measures in handling remain a concern. As the industry evolves, understanding these issues will be essential for maximizing its potential.