In recent years, 3D metal printed parts have transformed manufacturing. Experts, like Dr. Sarah Johnson, emphasize their potential. She once stated, “The future of manufacturing lies in additive technology.”

This innovation opens doors across industries. Aerospace, automotive, and medical fields benefit significantly. 3D metal printed parts offer customization and efficiency. However, challenges like material limitations and cost persist.

Exploring these advancements reveals both success and room for improvement. While production speeds increase, quality control remains a concern. The journey of 3D metal printing is ongoing. Each innovation prompts reflection on how to better harness this technology for future applications.

In 2026, innovations in 3D metal printing are making waves across multiple industries. New materials are being developed, enabling stronger and lighter parts. A report by Smithers states that the market is projected to reach $1.2 billion, reflecting the growing demand for advanced manufacturing solutions. This surge is driven by the aerospace and automotive sectors, which seek to improve efficiency.

Metal 3D printing technologies are advancing, but challenges remain. For instance, the cost of high-quality materials can be significant. The process can also be slow, impacting production timelines. A recent analysis indicated that nearly 30% of companies face performance issues with their printed parts. This necessitates continual innovation to enhance quality and reduce production times. Detailed optimization is essential in achieving consistency in metal printing.

Sustainability practices are being integrated into the design of 3D printed parts. For example, reducing material waste and energy consumption is a key focus. As industries strive for greener solutions, findings show that adopting metal printing can lower emissions by up to 50%. However, more research is needed to determine long-term impacts on sustainability. Overall, 3D metal printing offers exciting possibilities, despite facing some hurdles that require attention.

This chart illustrates key innovations in 3D metal printing projected for 2026, highlighting their impact on various sectors. The impacts are rated on a scale from 1 to 10, showing significant advancements in lightweight components and complex geometries.

3D metal printing has gained traction in several industries, driving innovation and efficiency. This technology allows for precise manufacturing of complex parts, which is increasingly crucial in fields like aerospace, automotive, and healthcare. According to recent industry reports, the global 3D metal printing market is expected to reach approximately $4.5 billion by 2025. Many companies are now optimizing designs that were once impossible to achieve with traditional methods.

In aerospace, 3D metal printing is replacing conventional parts to reduce weight. This can lead to better fuel efficiency and lower emissions. A study indicated that using metal 3D printed components can reduce aircraft weight by up to 30%. The automotive sector also benefits, with manufacturers producing lighter, stronger components using this technology. However, challenges remain. The quality control processes for 3D printed metals are under scrutiny. Variability in material properties can lead to failures in critical components.

Healthcare applications are promising yet complex. Metal implants that seamlessly fit patients can drastically improve recovery times. Yet, there are issues concerning biocompatibility. The safety of some 3D printed metals is not fully understood. Ongoing research is essential to ensure these innovations meet strict regulations and safety standards. As industries continue to explore 3D metal printing, balancing innovation with potential risks will remain vital.

| Application Area | Innovation Type | Material Used | Benefits |

|---|---|---|---|

| Aerospace Components | Lightweight Structures | Titanium Alloys | Reduced weight and improved fuel efficiency |

| Medical Devices | Customized Implants | Cobalt Chrome | Tailored fit and enhanced biocompatibility |

| Automotive Parts | Complex Geometries | Aluminum Alloys | Improved performance and reduced manufacturing time |

| Tooling Industry | Rapid Tooling | Steel Alloys | Faster production and cost-effective solutions |

| Energy Sector | Heat Exchangers | Nickel Alloys | Enhanced thermal efficiency and corrosion resistance |

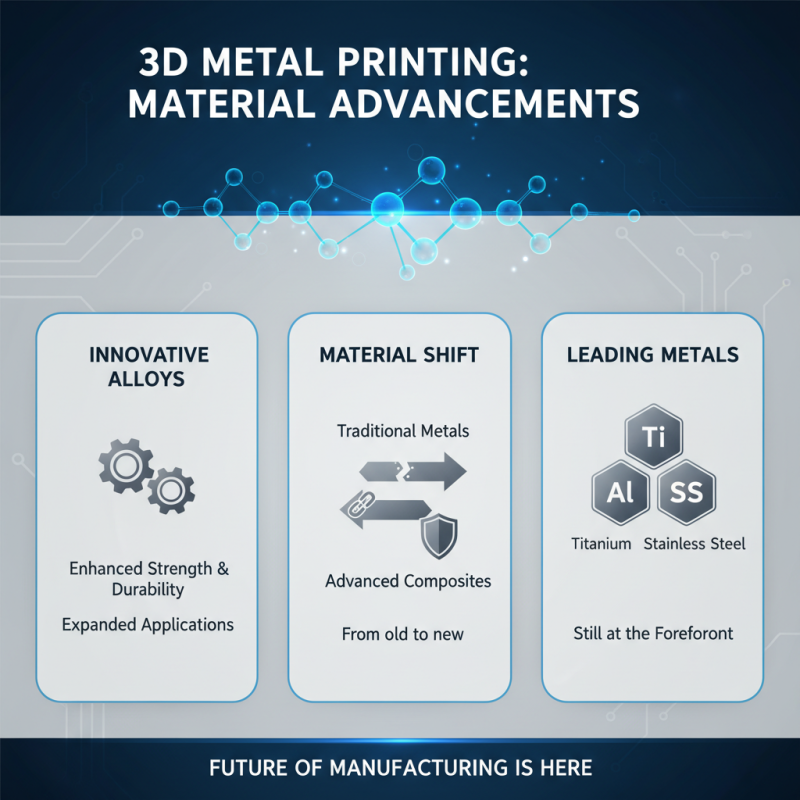

In recent years, 3D metal printing has shown significant advancements in materials used. Innovative alloys are now available for various applications. These materials enhance the strength and durability of printed parts. The shift from traditional metals to advanced composites is notable. Titanium, aluminum, and stainless steel continue to lead the way in metal 3D printing.

Certainly, the trend towards lightweight but robust materials is growing. For example, new high-performance metal powders offer better mechanical properties. These advancements enable engineers to design more complex geometries. The challenge lies in the consistency of these materials. Not every batch delivers the same results, which can lead to unexpected failures.

Tips: Always verify material specifications before starting a project. Consider running tests on smaller prints. This can save time and resources. Keep an eye on emerging materials as they can reshape your designs. Research is key; stay informed about new developments in the field. Embrace the imperfections, as they lead to innovation and breakthroughs.

3D metal printing technology has made significant strides recently. Yet, it is not without challenges. One major issue is the distortion during the printing process. As metal parts cool, they can warp. This affects the precision needed for high-quality parts. It’s crucial to manage temperature during printing. Some solutions involve using advanced cooling systems or adjusting print parameters.

Another challenge is the cost of materials. Metal powders can be expensive, limiting access for many users. This raises questions about material selection. Some techniques involve recycling unused powder, but this may compromise quality. Additionally, the layer-by-layer nature of 3D printing leads to longer production times. While it offers customization, it can be less efficient than traditional methods for mass production.

Lastly, post-processing remains a tricky aspect. Most printed parts require finishing to meet industry standards. This can add time and cost. Alternative methods are being explored, yet none are perfect. The exploration of these challenges shapes the future of 3D metal printing, pushing for innovations that will address these critical issues.

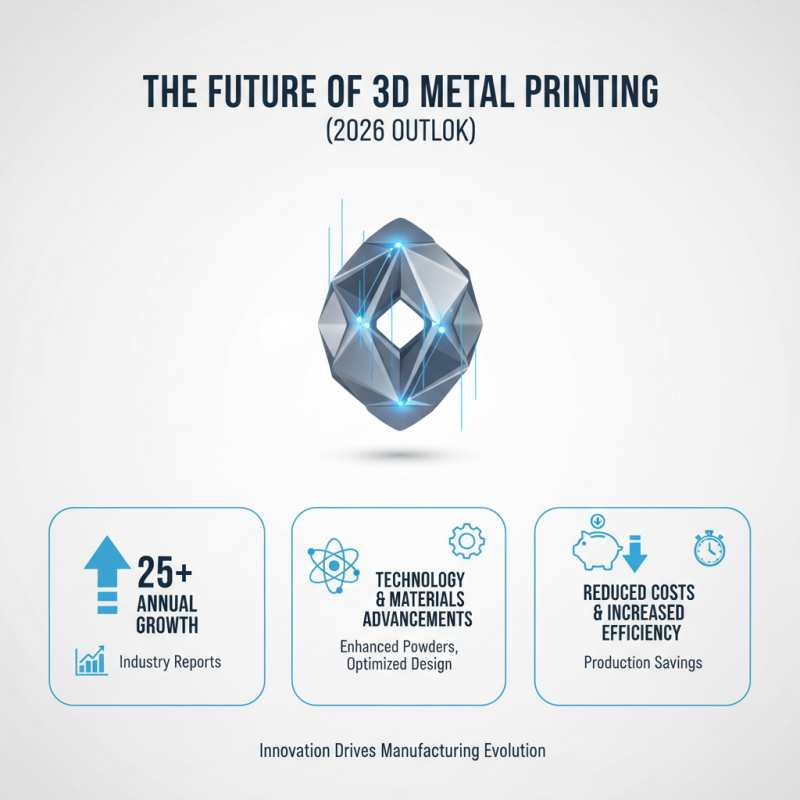

The future of 3D metal printing appears promising as we approach 2026. Recent industry reports indicate a projected growth of over 25% annually in the sector, fueled by advancements in technology and material sciences. Optimized design processes and enhanced metal powders are set to reduce production costs and increase efficiency.

Innovations in metal printing have led to applications in aerospace, automotive, and medical sectors. For instance, complex geometries that traditional methods cannot achieve are gaining traction in plane components. The challenge lies in material consistency and print reliability. Engineers often express concerns about defects in printed parts that can impact performance.

Looking beyond 2026, we anticipate a shift towards hybrid manufacturing processes. Combining 3D printing with traditional methods could yield stronger and more reliable components. However, the industry grapples with integrating these technologies effectively. Continuous research is necessary to address these imperfections and improve quality standards across various applications. Balancing innovation with practical application will be essential for the growth of this transformative technology.