Binder Jetting Solutions for OEMs and Manufacturers: Streamline Your Production

As a premier provider in the metal powder sector, we focus on Binder Jetting technology, offering advanced solutions tailored for OEMs and manufacturers. Our state-of-the-art Binder Jetting process ensures precise and efficient production of intricate geometries while optimizing material use. We cater to the distinct requirements of various industries, committed to supplying high-quality metal powders that enhance manufacturing operations.The Clear Choice of Binder Jetting From Concept to Delivery Manufacturer

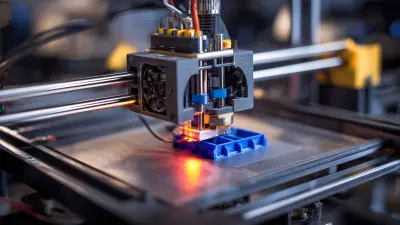

Binder Jetting is revolutionizing the manufacturing landscape, particularly in the field of metal powders. As a preferred method for producing intricate geometries and complex parts, it offers an efficient and cost-effective solution for modern industrial applications. Especially in industries such as aerospace, automotive, and additive manufacturing, Binder Jetting from concept to delivery ensures that clients receive products tailored to their unique specifications with remarkable precision. The journey of Binder Jetting begins with advanced research and development, where high-quality spherical Aluminum Powders and aluminum-based alloys play a crucial role. These materials are specifically engineered to enhance the sintering process, ensuring stronger and more durable end products. By utilizing state-of-the-art techniques in powder metallurgy, manufacturers can achieve superior mechanical properties, making them the ideal choice for demanding applications. Finally, the seamless transition from prototype to production means that global procurement partners can count on timely delivery without compromising quality. With a strong emphasis on innovation and collaboration, businesses can leverage Binder Jetting technology to transform their ideas into reality, ensuring they stay competitive in an ever-evolving market. Opt for Binder Jetting and experience the clear advantages it offers for your manufacturing needs.

The Clear Choice of Binder Jetting From Concept to Delivery Manufacturer

| Phase | Duration | Key Activities | Materials Used | End Product |

|---|---|---|---|---|

| Concept Development | 2 weeks | Idea brainstorming, design sketches | Digital CAD models | Prototype specifications |

| Material Selection | 1 week | Research on materials | Metal powders, polymers | Approved material list |

| Prototype Build | 4 weeks | 3D Printing process | Binder Jetting materials | Functional prototype |

| Testing and Validation | 3 weeks | Performance testing | Prototype and standards | Validated product |

| Production Preparation | 2 weeks | Final adjustments to design | Manufacturing setup | Production-ready design |

| Full Production | Ongoing | Mass production | Final materials | Market-ready product |

Best Way To Binder Jetting Dominates Pioneers in the Field

J

James Thompson

The quality speaks for itself, but the outstanding customer service was the cherry on top!

03 July 2025

J

Jacob Edwards

The craftsmanship is excellent. I was very pleased with the customer service I received.

16 June 2025

A

Abigail Stewart

This product is a game-changer! The support staff were courteous and very knowledgeable.

12 May 2025

M

Matthew Hill

Premium quality and fantastic service! The staff was very engaging and knowledgeable.

02 July 2025

W

William Turner

Highly recommend this product! The support team was attentive and responsive.

01 June 2025

S

Sophie Collins

A great purchasing experience! The quality is impressive and the support team is amazing.

30 May 2025